Bionic rope-driven four-degree-of-freedom arm for man-machine cooperation

A technology of human-machine collaboration and degrees of freedom, applied in manipulators, claw arms, manufacturing tools, etc., can solve the problems of increasing joint volume, weight, small load self-weight, poor flexibility, etc., to improve safety, reduce mechanism damage, environmental protection The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0027] The preferred embodiment of the human-machine collaboration-oriented bionic rope-driven four-degree-of-freedom arm of the present invention is:

[0028] Including shoulder structure, elbow joint, wrist joint, rope drive device, decoupling layout between joints, joint stiffness amplification device, upper arm and lower arm;

[0029] The elbow joint is a tangential circular rolling structure, which is equivalent to a single-degree-of-freedom rotary joint, and the stiffness and torque amplification of the joint is realized through the pulley block;

[0030] The wrist joint is a three-degree-of-freedom joint, two of which are realized through a three-link parallel mechanism, and the third rotational degree of freedom is realized through a universal joint and a rotating shaft;

[0031] The driving motors of the above four degrees of freedom are all arranged at the shoulder structure, and the driving motors drive each joint through the transmission rope and the transmission p...

specific Embodiment

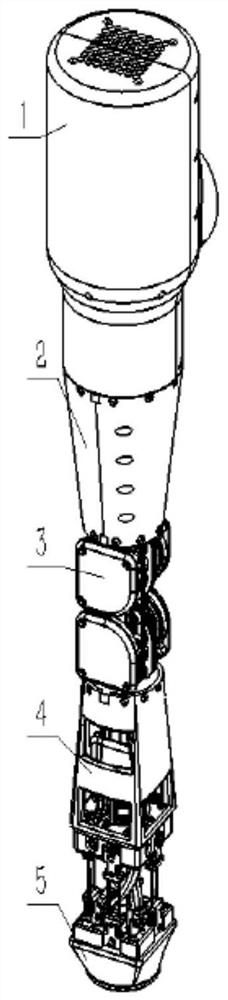

[0056] Such as Figure 1a , Figure 1b to Figure 10 As shown, the mechanical arm is composed of a shoulder structure 1 , an elbow joint 3 , a wrist joint 5 , an upper arm 2 and a lower arm 4 . The shoulder is equipped with driving motors for the elbow joint and wrist joint, a transmission screw group and a transmission rope guide pulley group; the elbow joint has one degree of freedom, and the pure rolling structure is used to realize the movement of the elbow joint, and the motor driving the elbow joint is arranged in the shoulder structure position, which can effectively reduce the moment of inertia of the arm; the wrist joint has three degrees of freedom, of which two degrees of freedom are tilted and flexed through a three-link parallel mechanism, and two sets of pulley blocks are used to achieve movement in these two directions. The third degree of freedom Rotational movement is realized by driving the shaft connected to the Hooke hinge through the rope wheel. The three m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com