Seat frame for motorcycle

A technology for two-wheeled motor vehicles and seat frames, applied in the direction of motor vehicles, bicycle racks, bicycle saddles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

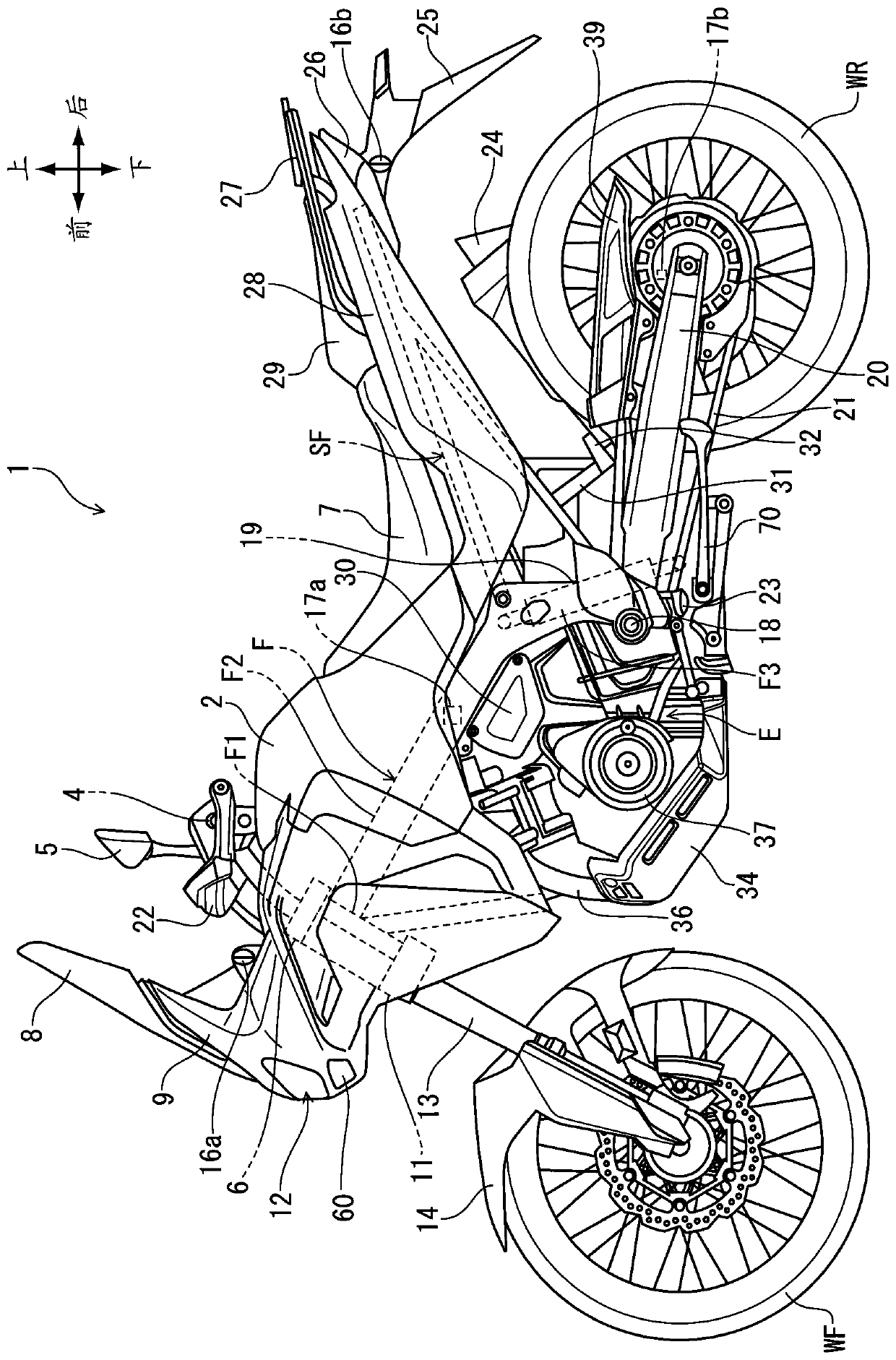

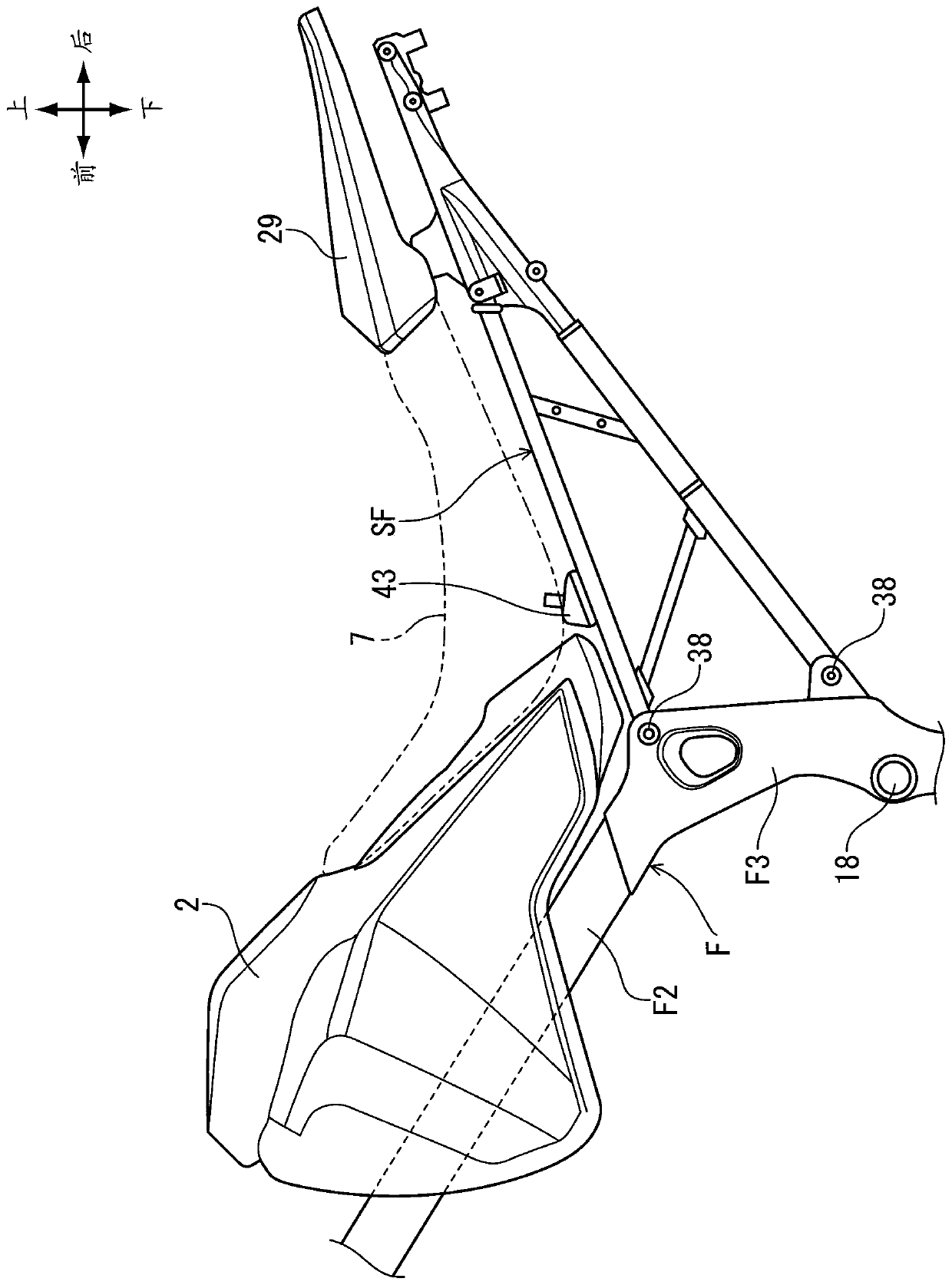

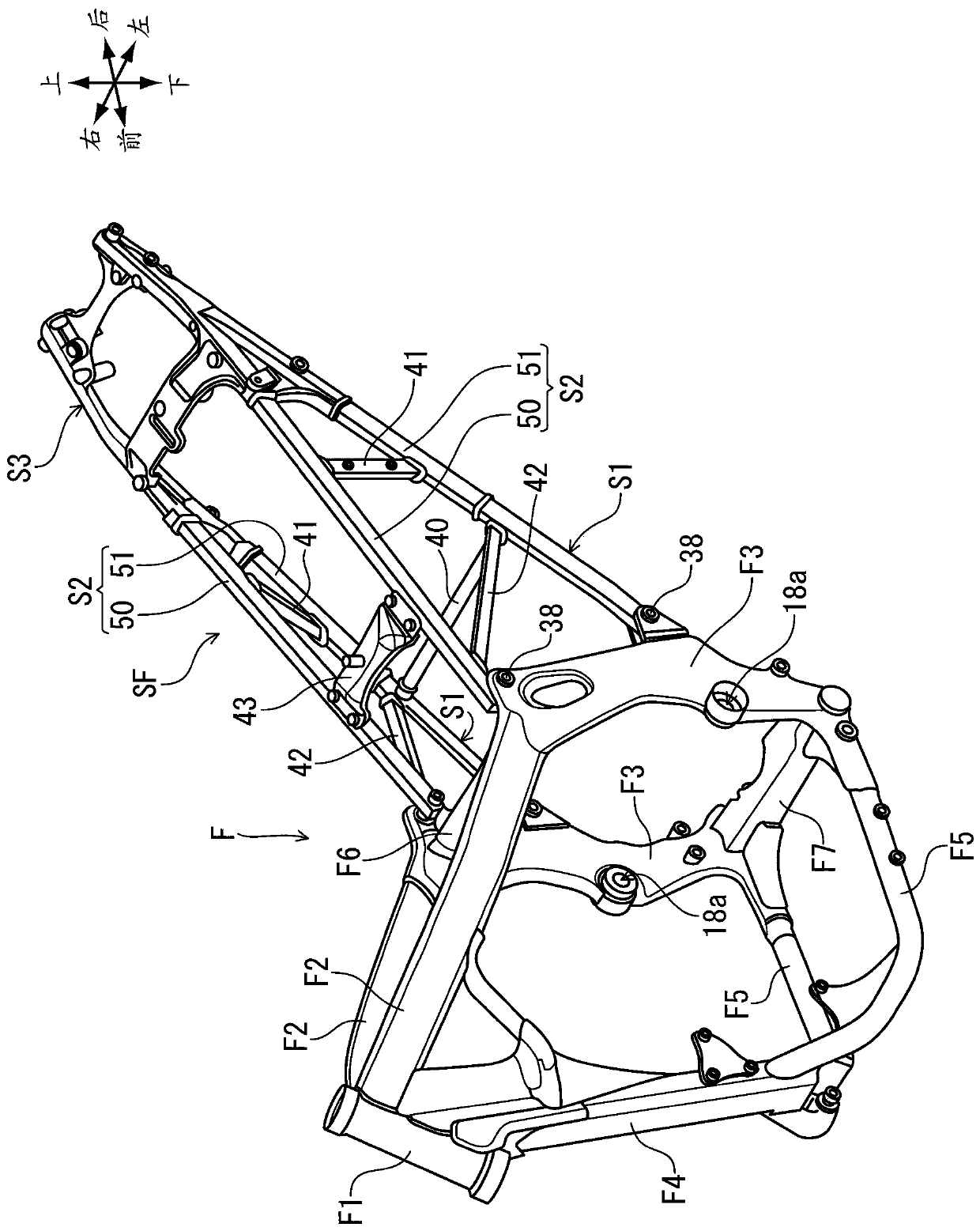

[0038] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a left side view of the motorcycle 1 to which the seat frame SF of one embodiment of this invention is applied. The two-wheeled vehicle 1 is a dual-purpose saddle-riding type vehicle that travels by transmitting the driving force of the engine E serving as a power source to the rear wheels WR using a transmission chain 21 . At vehicle body front end portions of a pair of left and right main frames F2 constituting the vehicle body frame F, a head pipe F1 pivotally supporting an unillustrated steering shaft is provided. A pair of left and right front forks 13 that rotatably pivotally support the front wheel WF are supported by a top beam 6 and a bottom beam 11 fixed to the steering shaft above and below the head pipe F1. A pair of left and right rearview mirrors 5 and a knuckle cover (nack guard) 22 are attached to the steering handle 4 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com