Electromagnetic valve and air conditioning system

A solenoid valve, moving iron core technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of large flow resistance, large pressure loss, short stroke, etc., to reduce pressure loss, increase distance, reduce The effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

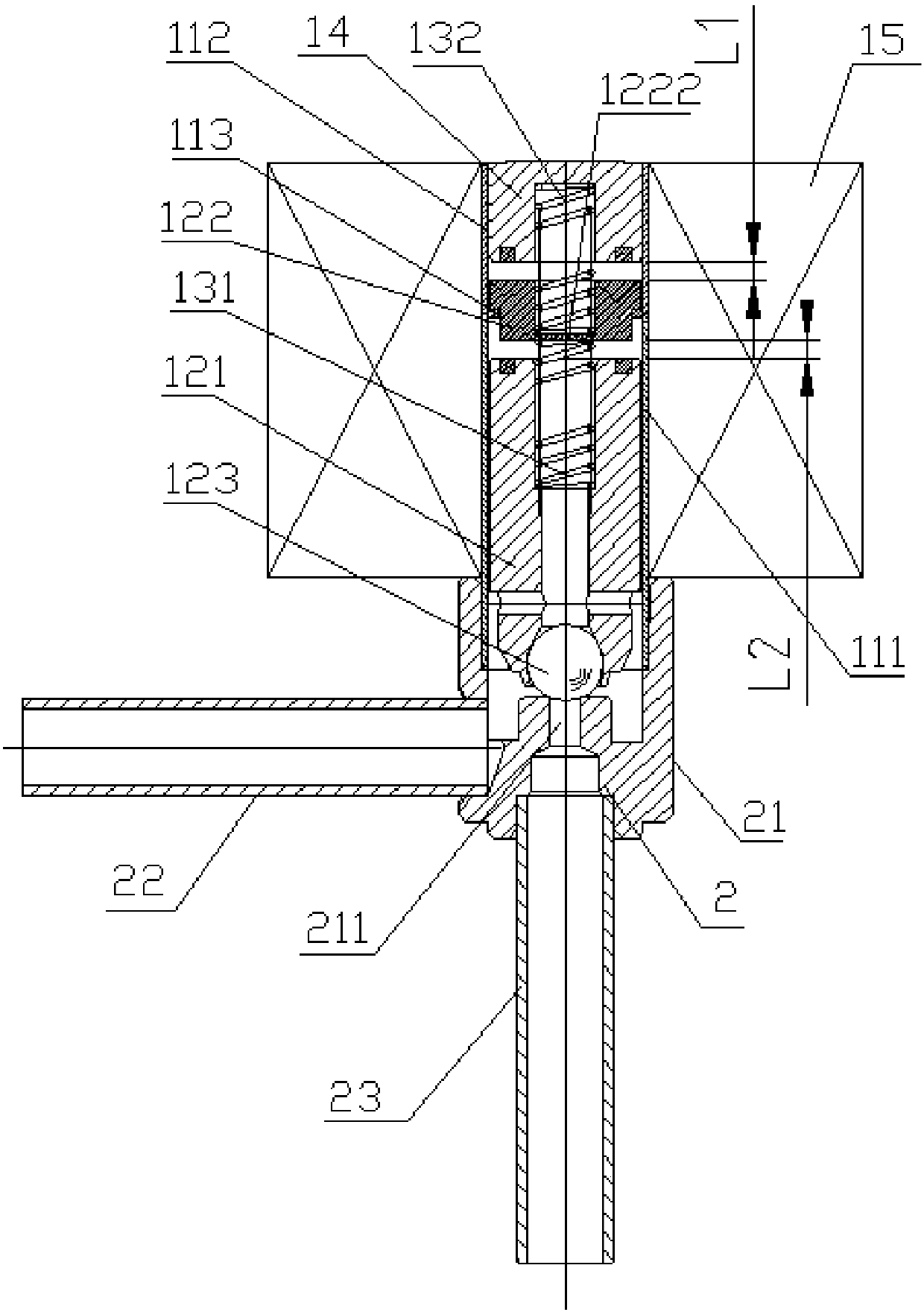

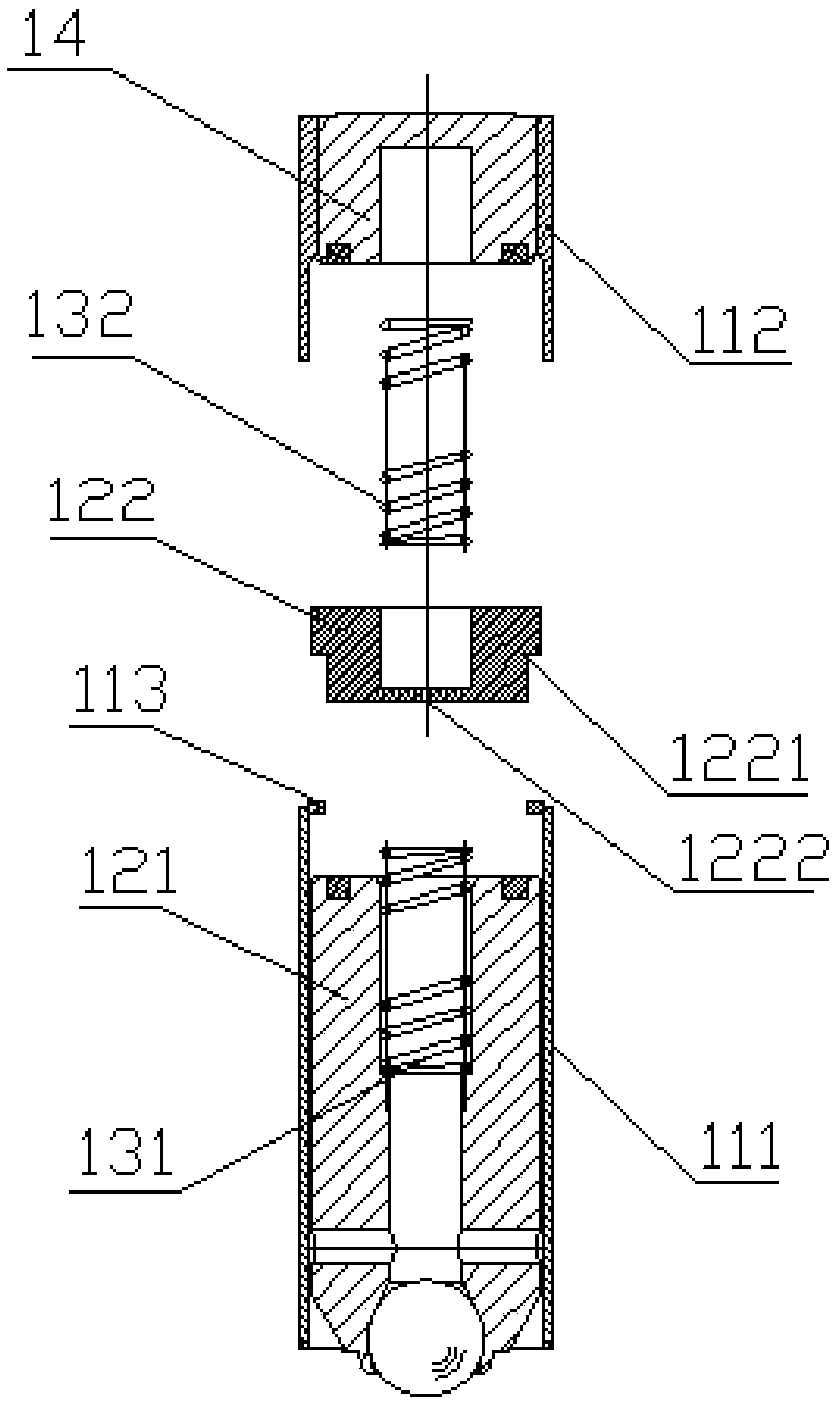

[0030] Embodiment one, such as figure 1 with figure 2 As shown, a solenoid valve includes a valve body part 2 and an electromagnetic control part 1, wherein the valve body part 2 includes a valve body 21 with a first interface and a second interface, the first interface is connected to the first connecting pipe 22, and the second The interface is connected to the second connecting pipe 23 , and the valve body 21 is provided with a valve port 211 communicating with the second interface. The electromagnetic control part 1 includes a casing, a coil 15 arranged outside the casing, a static iron core 14 installed at the rear end of the casing, and a moving iron core arranged in the casing, and the moving iron core includes a first moving iron core arranged separately. An iron core 121 and a second moving iron core 122, the first moving iron core 121 is located in front of the second moving iron core 122 and a first return spring 131 is arranged between the first moving iron core ...

Embodiment 2

[0036] Embodiment 2, on the basis of Embodiment 1, in order to further ensure that the first moving iron core 121 and the second moving iron core 122 are attracted first when the coil 15 is energized, and then the second moving iron core 122 is connected with the first moving iron core 121 Together with the static iron core 14 suction, and to avoid malfunction. It can be set in such a way that the suction force between the first moving iron core 121 and the second moving iron core 122 is greater than the suction force between the second moving iron core 122 and the static iron core 14 when the coil 15 is energized.

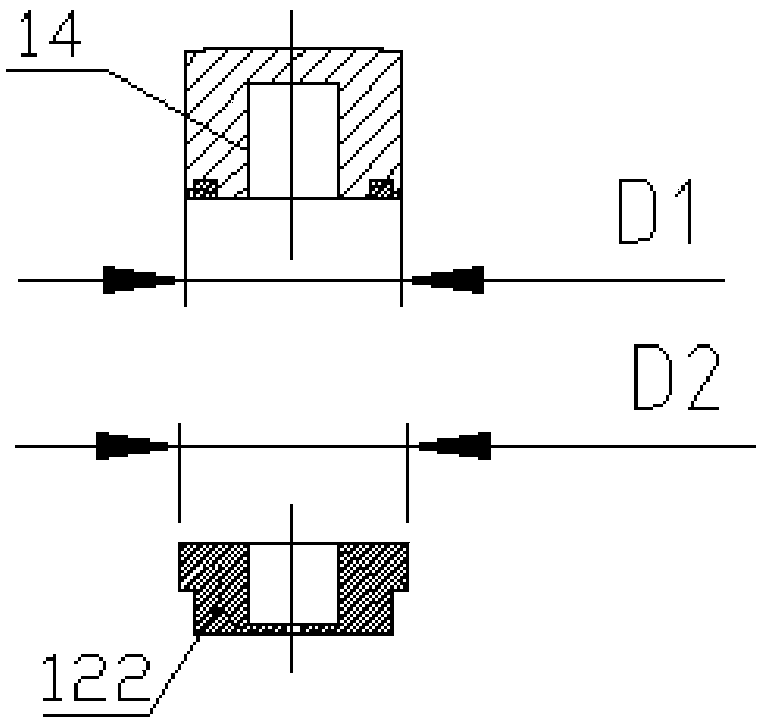

[0037] refer to figure 1 As shown, when the coil 15 is powered off, the first moving iron core 121 , the second moving iron core 122 and the static iron core 14 are separated by the first return spring 131 and the second return spring 132 . Wherein, the distance between the second moving iron core 122 and the static iron core 14 is L1, the distance between the fi...

Embodiment 3

[0043] Embodiment 3, an air conditioning system is provided with the above-mentioned solenoid valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com