Variable servo valve, power servo valve and variable pump

A power valve and servo valve technology, applied in the field of hydraulic controllers, can solve the problems of difficult processing and assembly, a large number of parts, and high cost, and achieve the effects of reducing assembly difficulty and cost, adjusting power and displacement, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

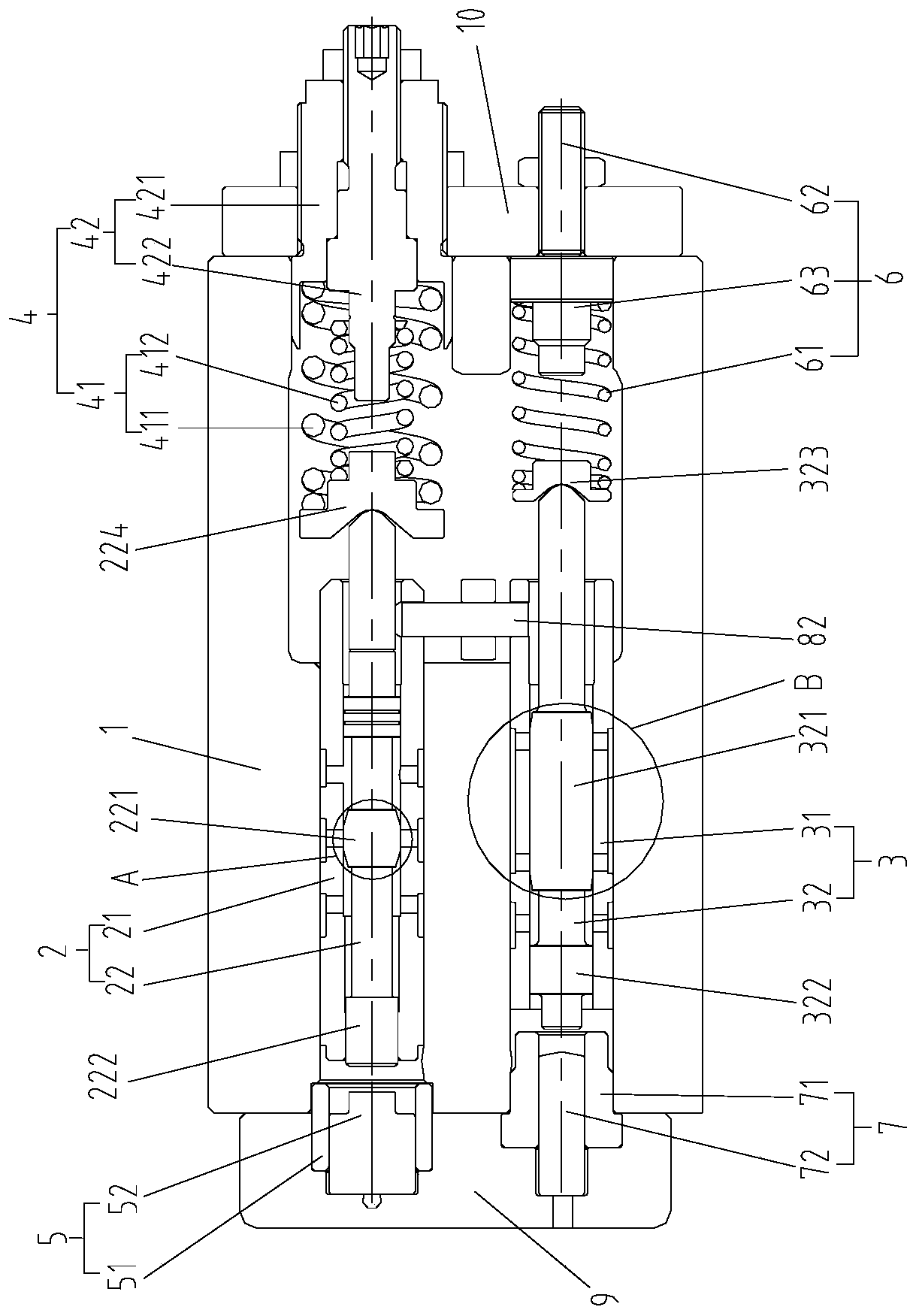

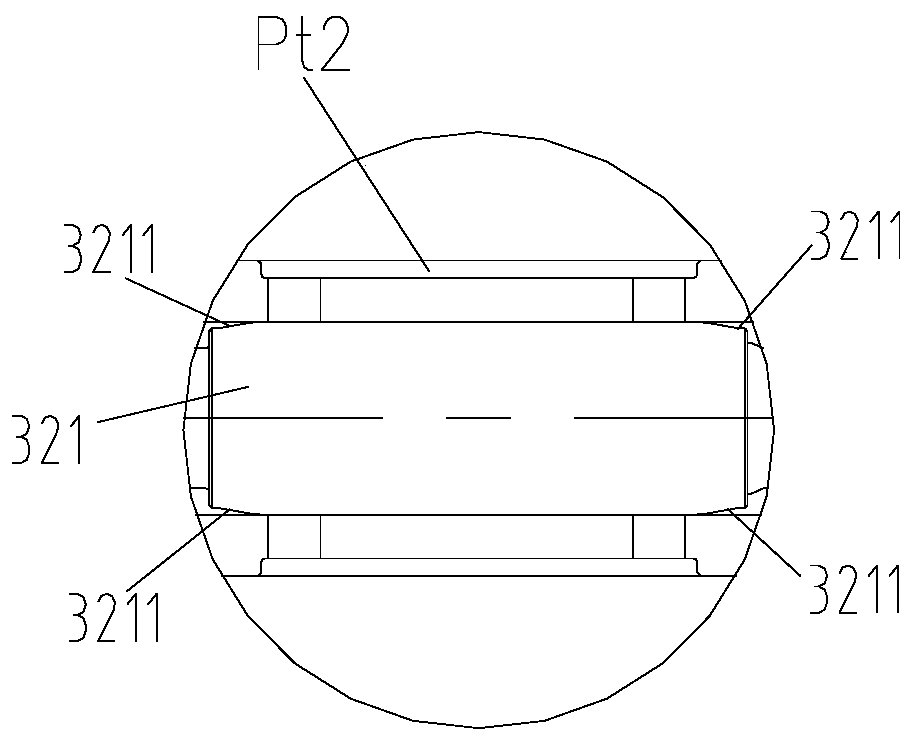

[0046] Such as Figure 1-11 As shown, this embodiment provides a variable variable servo valve, which includes a valve body 1, and a power valve 2 and a displacement valve 3 are arranged side by side in the valve body 1. Specifically, two installation holes are opened in parallel in the valve body 1. The power valve 2 and the displacement valve 3 are respectively arranged in two mounting holes. The power valve 2 and the displacement valve 3 can realize the power control and displacement control of the variable displacement pump by controlling the movement of the servo piston. The power valve 2 and the displacement valve 3 can be controlled separately or cooperatively.

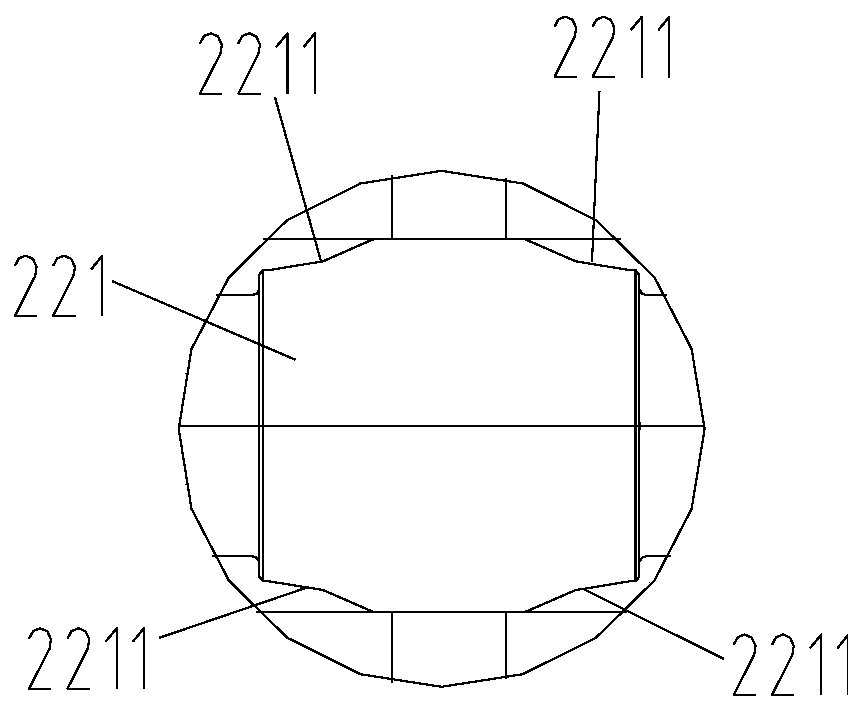

[0047] The power valve 2 includes a power valve sleeve 21 and a power valve core 22 , the power valve sleeve 21 is axially slidably disposed in the valve body 1 , and the power valve core 22 is axially slidably disposed in the power valve sleeve 21 . The power valve sleeve 21 is opened with the pressure oil p...

Embodiment 2

[0062] Such as Figure 12 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that there are two pressure oil ports Po1 of the power valve sleeve, and the pressure oil ports Po1 of the two power valve sleeves are used to connect pressure oil, and the power valve core 21 is also provided with a third core 223, the third core 223 is located on the side of the second core 222 away from the first core 221, the outer diameter of the third core 223 is D3, D1>D2>D3, An area difference S1 is formed between D1 and D2, and an area difference S2 is formed between D2 and D3, forming two pressure steps. The pressure oil ports Po1 of the two power valve sleeves are respectively located between the first core 221 and the second core 222 and between the second core 222 and the third core 223 . The force direction of the pressure oil entering through the pressure oil port Po1 of the two power valve sleeves on the power spool 22 is opposite to the force dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com