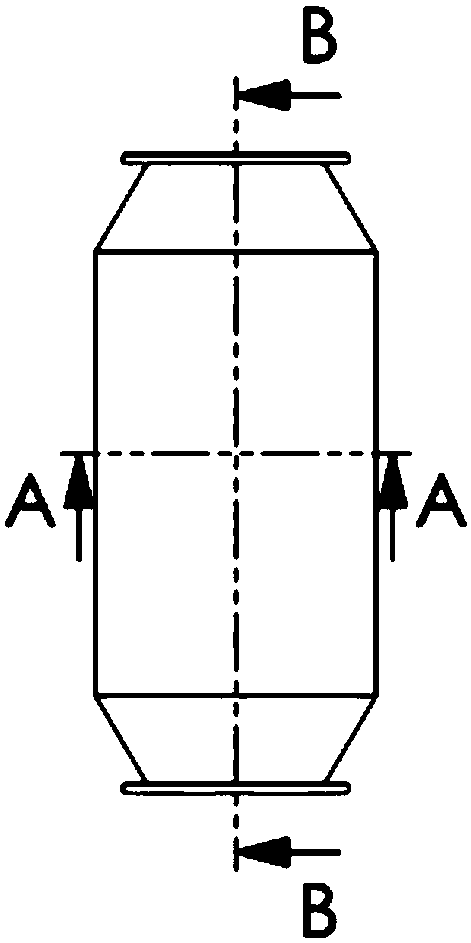

Vacuum pump silencing device

A noise reduction device and vacuum pump technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problem of excessive noise at the vacuum pump exhaust port, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

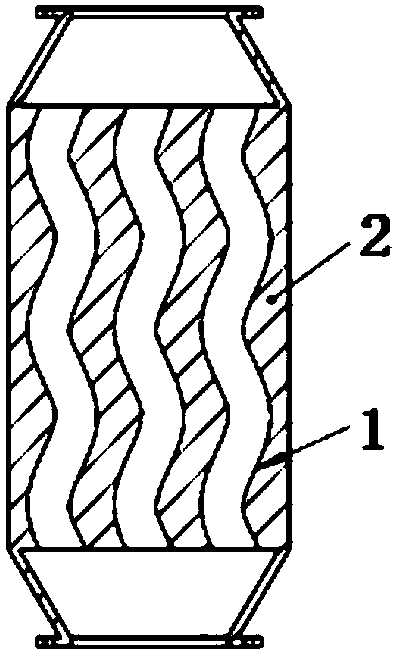

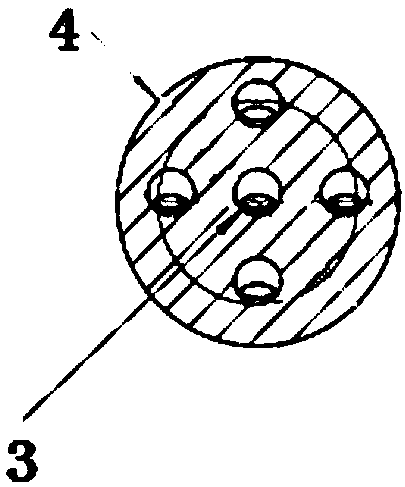

[0026] The vacuum pump muffler device of the present invention uses DN450 outer pipes to cover the internal sound-absorbing material, and arranges five DN80 muffler pipes in a cross shape inside, and the muffler pipes are arranged in an S-shape to increase the internal sound-absorbing stroke and reduce noise. The perforated sound insulation board is installed outside the pipe for primary sound absorption, and the polyester fiber sound-absorbing cotton is filled outside the perforated sound insulation board for secondary sound absorption. The noise of the vacuum pump evacuating the air is partially absorbed inside the muffler.

[0027] The measured noise at the exhaust port of the original vacuum pump is up to 85 decibels, and the measured minimum is 80 decibels. After using this vacuum pump silencer device, the measured noise control is up to 64 decibels, and the measured minimum is 60 decibels, which effectively reduces the noise of the vacuum pump and makes the vacuum pump rea...

Embodiment 2

[0029] A vacuum pump noise reduction device, the vacuum pump noise reduction device is installed at the outlet of the vacuum pump exhaust port, the vacuum pump noise reduction device includes a flange, a noise reduction pipe, and a punched sound insulation board;

[0030] - the flange, the first end is connected to the flange of the outlet end of the vacuum pump, and the second end is connected to the inner pipe of the evacuation outlet pipeline of the vacuum pump;

[0031] - the silencer pipe, which is arranged in an S shape inside the outer pipe of the vacuum pump's evacuation outlet pipe;

[0032] -Punched sound insulation board, wrapped on the outer wall of the sound deadening pipe.

Embodiment 3

[0034] The difference from Embodiment 1 is that the polyester fiber sound-absorbing cotton is also included, and the polyester fiber sound-absorbing cotton is filled inside between the perforated sound-insulating board and the outer pipe of the vacuum pump's evacuation outlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com