Self-resetting whole assembly type friction energy dissipation steel frame beam-column joint

A technology of friction energy consumption and beam-column joints, which is applied in the direction of protective buildings/shelters, building components, building types, etc., can solve the problems of beam-column joints lack of plastic rotation capacity, large residual deformation, and difficult to repair, etc. Achieve the effect of convenient and quick repair, improve stability, and reduce damage to the main structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

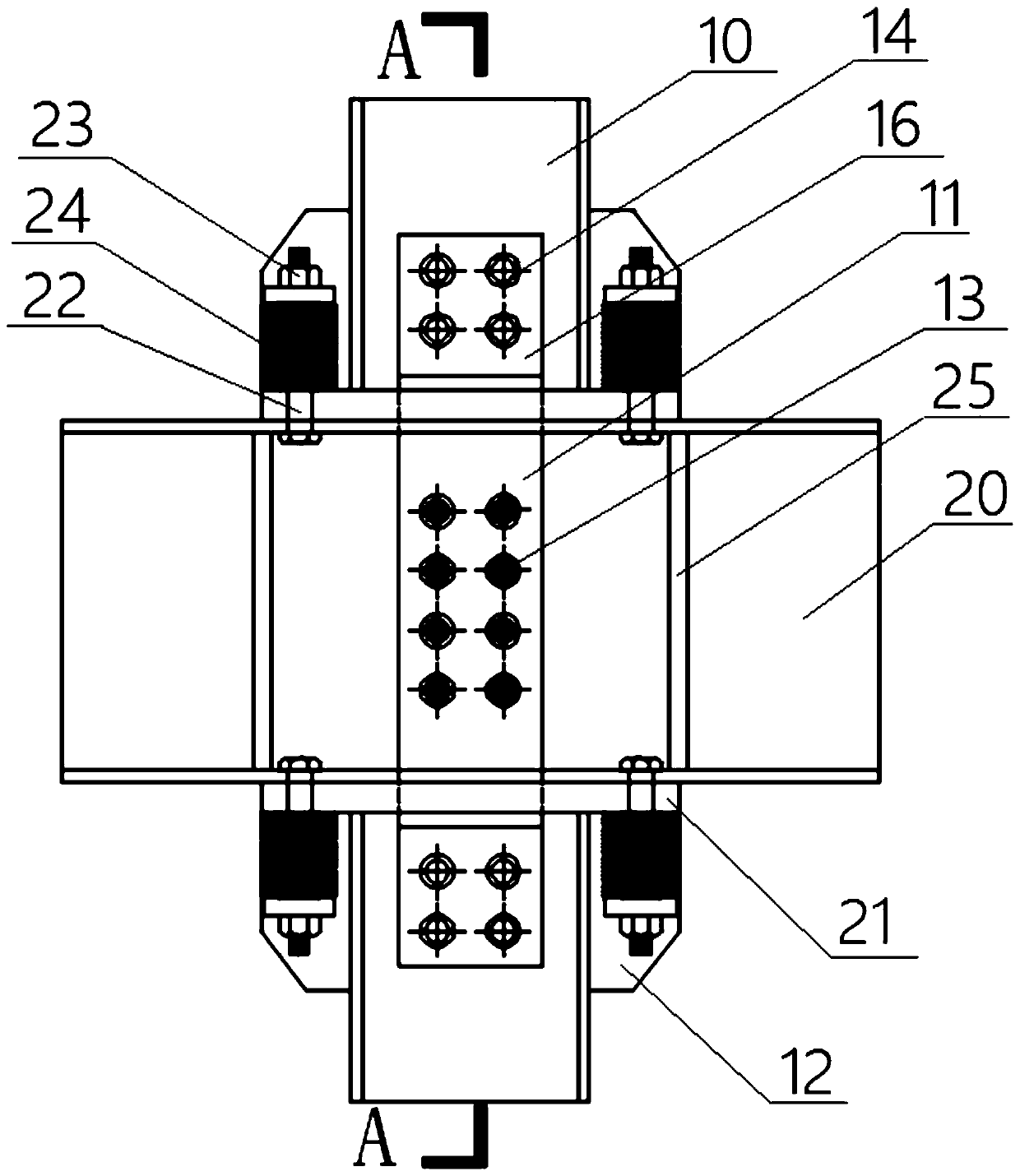

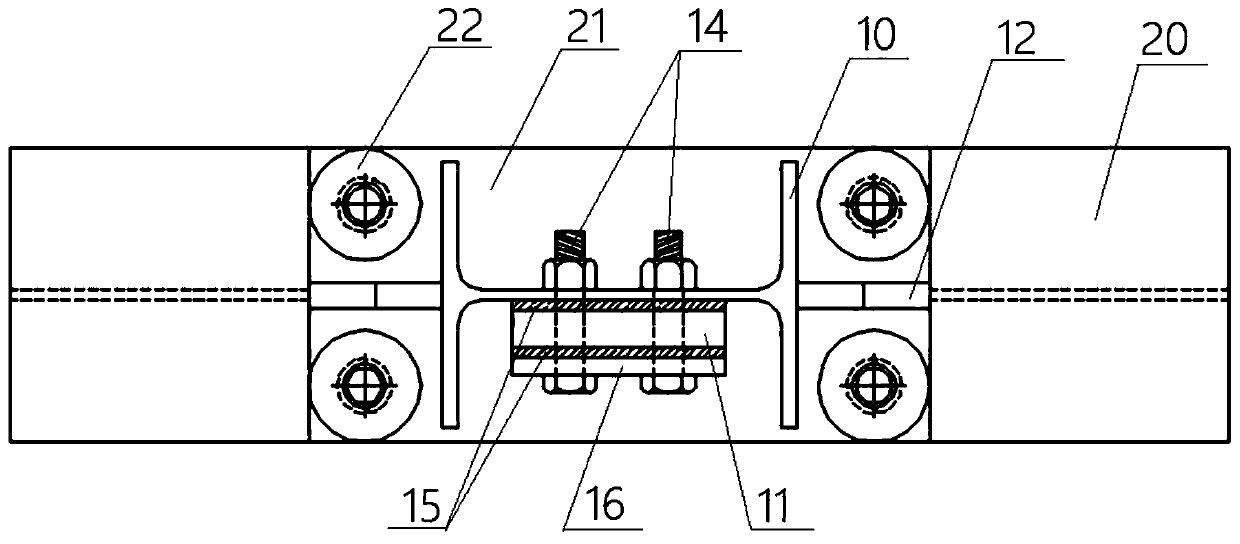

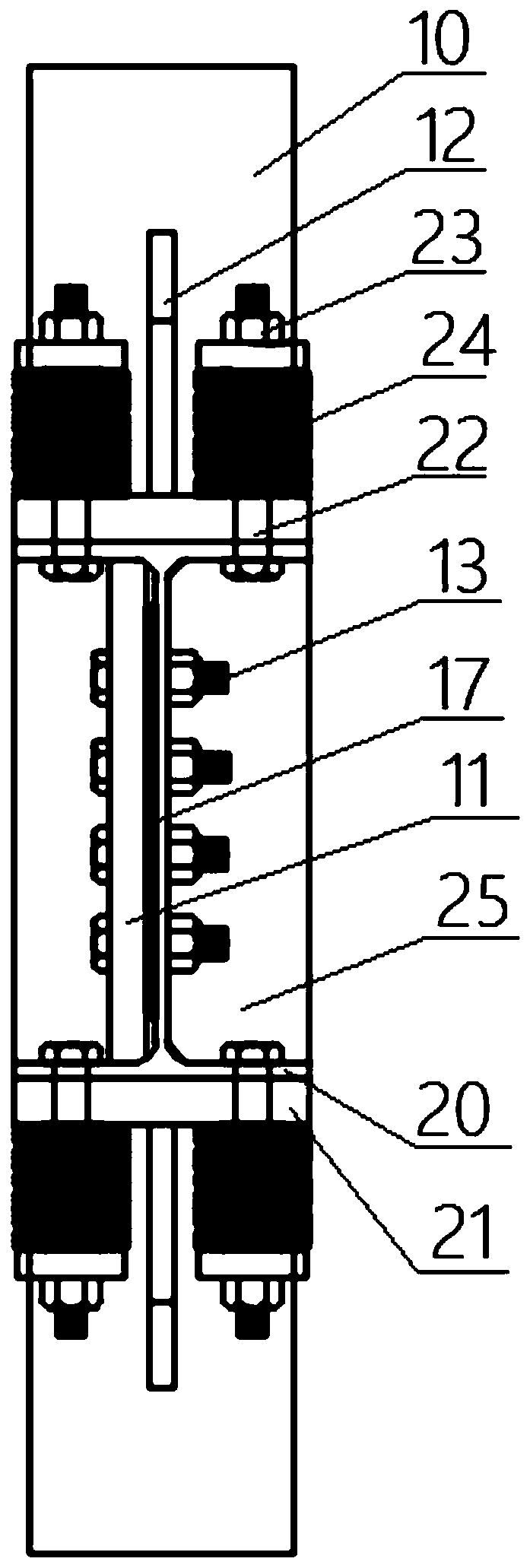

[0026] refer to Figure 1-Figure 4 , the self-resetting fully assembled frictional energy-dissipating steel frame beam-column node of the present invention includes a longitudinal swing column 10, a transverse frame beam 20, a beam-column connection riser 11, a beam-column connection bottom plate 21, and a boot beam plate 12, and the swing The cross sections of the column 10 and the frame beam 20 are both H-shaped, including a web in the middle and flanges on both sides. The swing column 10 is disconnected, and the upper and lower column sections are respectively located above the upper flange and below the lower flange of the frame beam 20, and a beam-column connection base plate 21 is provided between the swing column 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com