Heat-preservation humidity-adjusting dry-powder diatom ooze and preparation method thereof

A technology of diatom mud and dry powder, which is applied in the field of thermal insulation and decorative functional materials, can solve the problems of diatom mud not being able to give full play to the function, uneven quality, easy powder falling and cracking, etc., to achieve obvious three-dimensional effect and strong ability to decompose formaldehyde , Improve the effect of constructability and modeling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

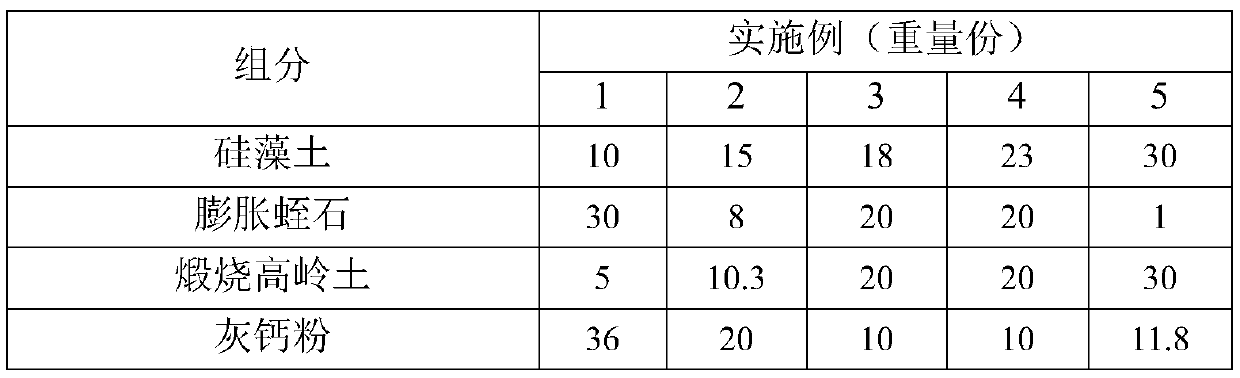

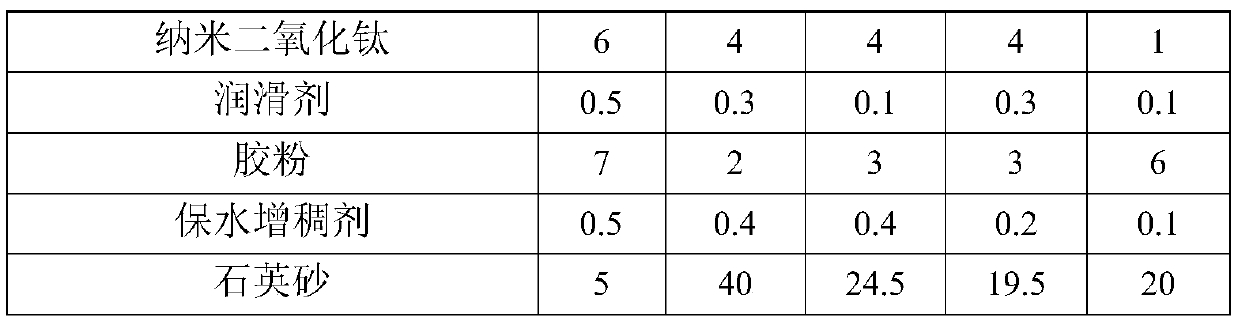

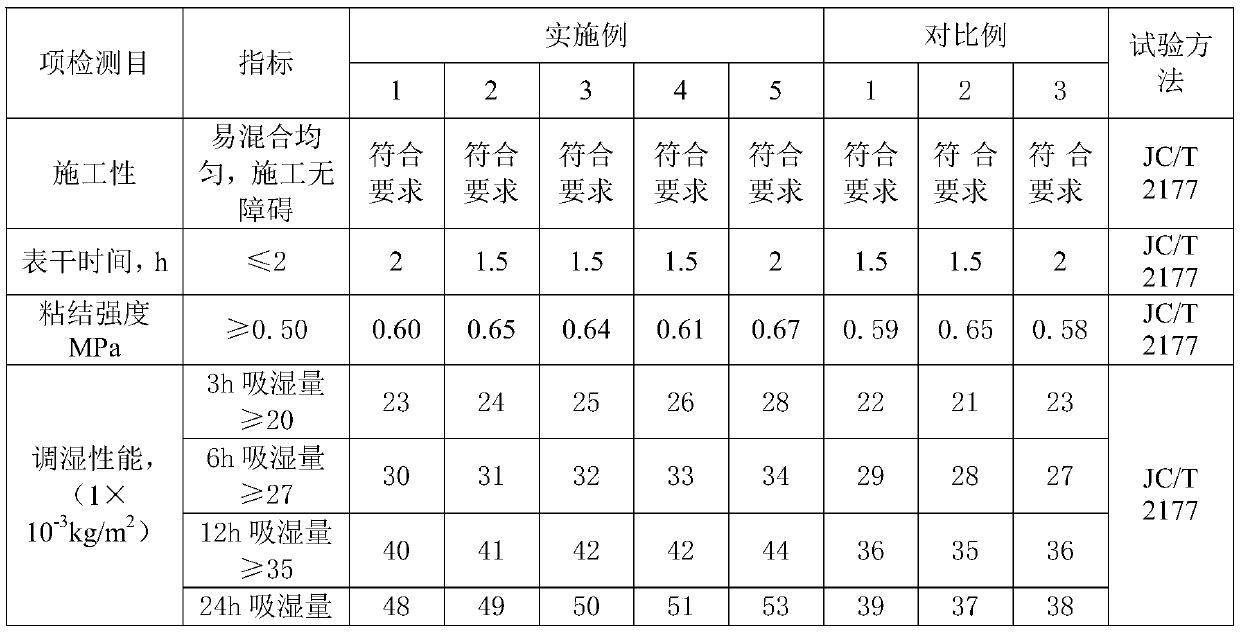

[0036] Examples 1 to 6 relate to a heat-preserving and humidity-adjusting dry powder diatom ooze and a preparation method thereof. The components and dosages of the heat-retaining and humidity-adjusting dry powder diatom ooze are shown in Table 1.

[0037] The preparation method includes the following steps: adding the diatomite, expanded vermiculite, calcined kaolin, lime calcium powder, nano-titanium dioxide, lubricant, rubber powder, water-retaining thickener, and quartz sand into a dry mixing mixer in sequence , fully mixed evenly, that is, heat preservation and humidity control dry powder diatom mud.

[0038] Then according to different shapes and construction requirements, the amount of water added is between 30% and 60%, and the water can be added and stirred evenly before construction and use.

[0039] Table 1

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com