Efficient automatic car wiping equipment and application method thereof

An automatic and equipment technology, applied in vehicle cleaning equipment, vehicle maintenance, vehicle cleaning, etc., can solve the problems of low efficiency of manual drying and affecting the enthusiasm of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] see Figure 1-3 , In an embodiment of the present invention, a high-efficiency automatic car cleaning device includes a housing, the upper part of the housing is a drying compartment, and the lower part is a lifting equipment compartment and a drying equipment compartment. There is a vehicle entrance on one side of the casing, and a lifting door is arranged above the vehicle entrance. The lifting door is installed on the side wall of the casing through a slide rail, and a servo motor is installed at the slide rail. The servo motor can drive the lifting door to descend to close the vehicle entrance.

[0022] The inner wall of the drying chamber is provided with four symmetrical mechanical arms, the ends of the mechanical arms are provided with micro motors, the output shaft of the micro motors is provided with a towel mounting plate, and the dry towels are installed at the bottom of the towel mounting plate. Several hydraulic cylinders are evenly arranged in the lifting ...

Embodiment 2

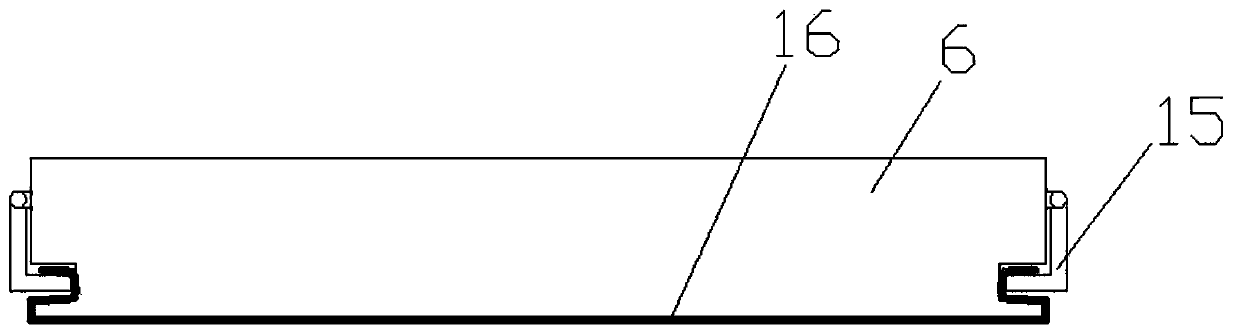

[0026] There are grooves on both sides of the towel mounting plate, and an L-shaped buckle is hinged above the groove. A coil spring is provided at the connection between the buckle and the towel mounting plate. After the towel is placed on the bottom of the towel mounting plate, the end of the towel covers the groove , at this moment, the buckle fixes the towel under the action of the spring force.

Embodiment 3

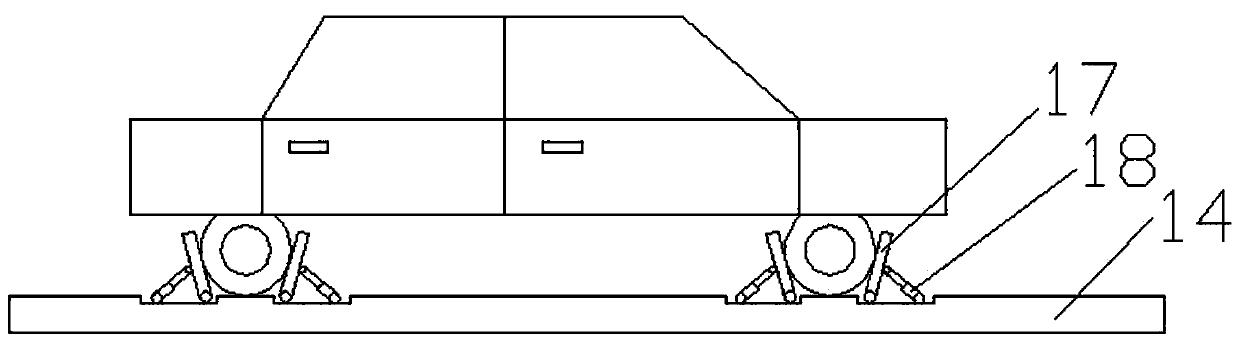

[0028] The four positions on the lifting plate corresponding to the wheels are respectively equipped with car body fixing devices. The car body fixing devices include wheel splints and cylinders. There are four sinking grooves on the upper surface of the lifting plate, and the wheel splints and cylinders are hinged in the sinking grooves. After the vehicle stops on the lift plate, the cylinder drives the wheel splint to clamp the four wheels to prevent the vehicle from moving due to accidents and avoid accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com