Differential pressure type profiling matrix cylinder group mechanism

A cylinder group and differential pressure technology, which is applied in the field of sanding machines, can solve problems such as uneven pressure, omission of processing areas, and low yield rate, and achieve the effects of increased adaptability, high resolution, and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

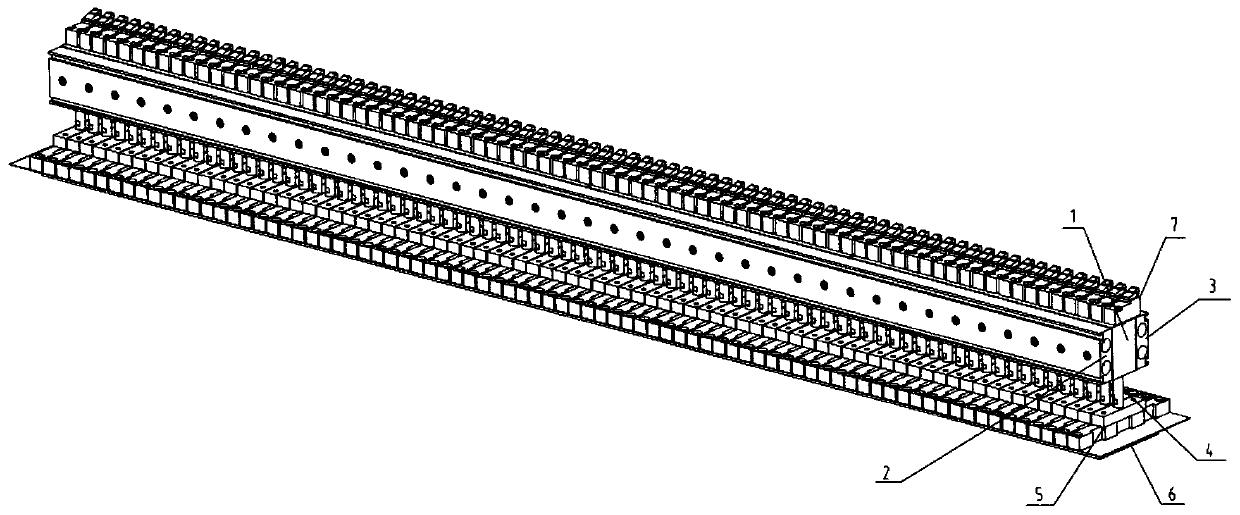

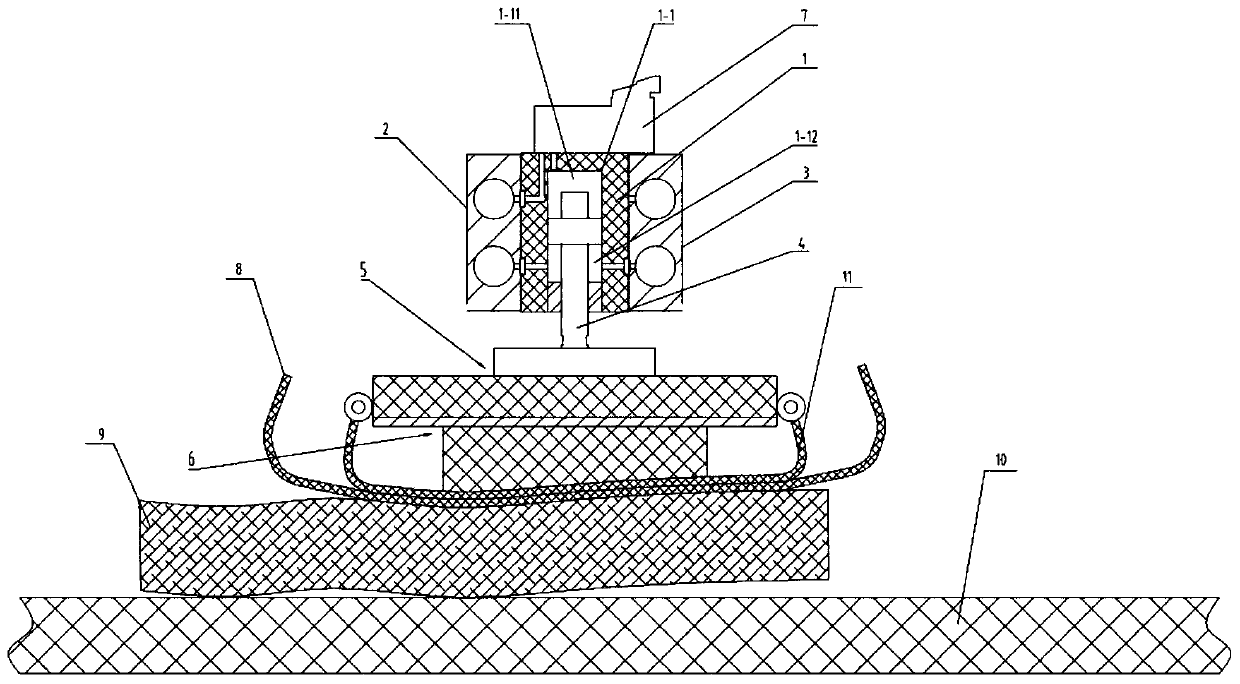

[0015] Embodiment 1, as figure 1 , 2 As shown, a pressure difference type profiling matrix cylinder group mechanism includes a matrix cylinder block 1 arranged horizontally, and a left air circuit board 2 and a right air circuit board 3 are respectively arranged on both sides of the matrix cylinder block 1. A cylinder cavity 1-1 is horizontally arranged in the cylinder body 1, and a piston column 4 is evenly arranged in the cylinder cavity 1-1, and a connecting piece 5 is provided at the end of the piston column 4, and a flexible piece is provided at the bottom of the connecting piece 5. The backing plate 6, the top of the matrix cylinder block 1 is also provided with a control valve 7 corresponding to the piston rod 4 one by one.

Embodiment 2

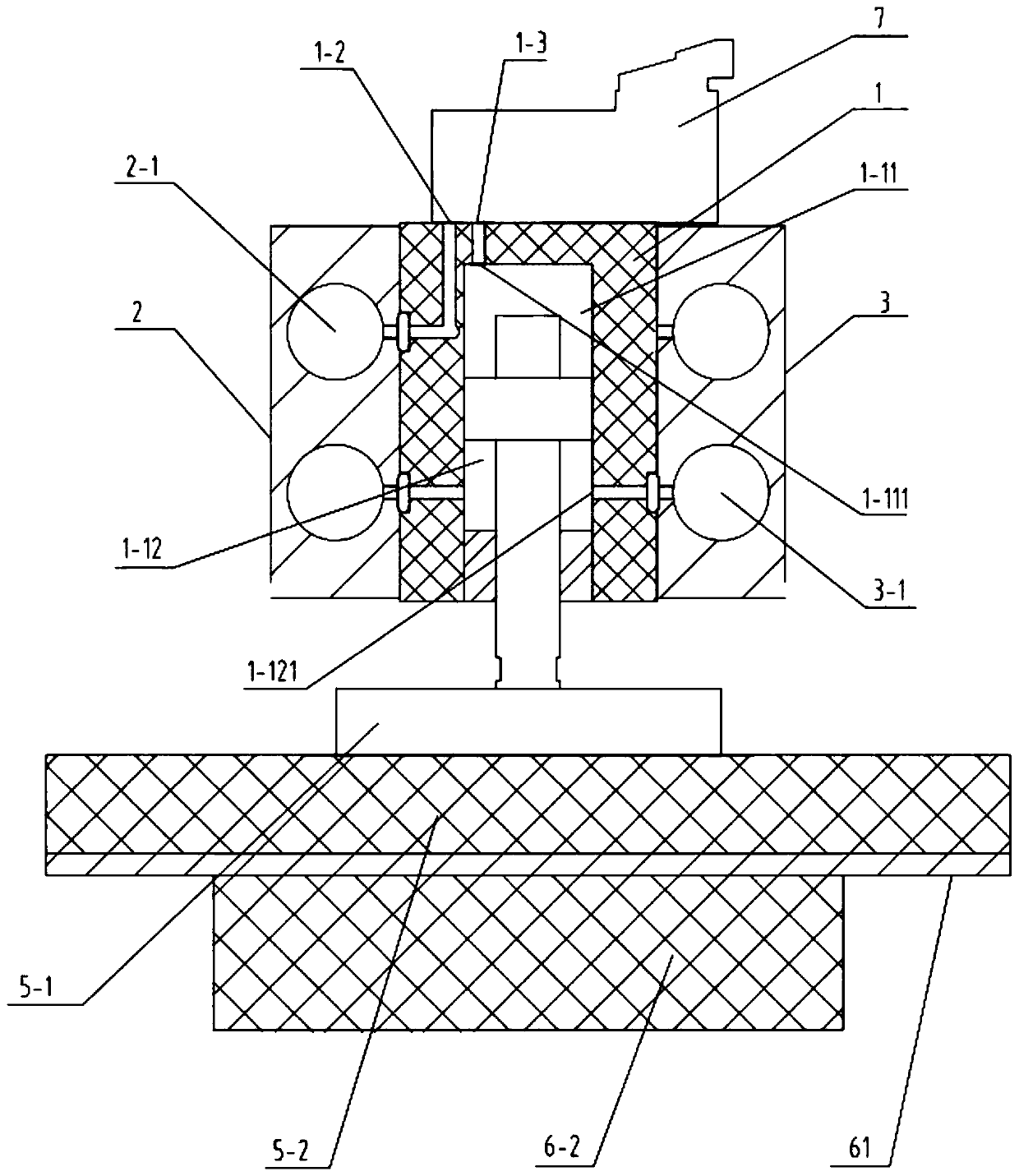

[0016] Embodiment 2, as figure 1 , 2 , 3, on the basis of Embodiment 1, the cylinder cavity 1-1 is composed of an upper air chamber 1-11 and a lower air chamber 1-12, and the piston rod 4 is formed between the upper air chamber 1-11 and the lower air chamber 1-12. The air chamber 1-12 performs reciprocating motion; the left air circuit board 2 is provided with a left air intake hole 2-1, and the top of the matrix cylinder body 1 is provided with a cylinder air intake hole 1-2 and a cylinder air outlet hole 1-3 , the upper air chamber 1-11 is provided with an upper air chamber air inlet 1-111, the right air circuit board 3 is provided with a right air inlet 3-1, and the lower air chamber 1-12 is provided with a lower air inlet chamber air intake hole 1-121; the left air intake hole 2-1 communicates with the cylinder air intake hole 1-2, the cylinder air intake hole 1-2 communicates with the control valve 7, and the control valve 7 communicates with the The air outlet hole 1-3...

Embodiment 3

[0017] Embodiment 3, as figure 1 , 2 , 3, on the basis of Embodiment 1, the connecting piece 5 comprises an aluminum block 5-1 and a plastic block 5-2, the aluminum block 5-1 is placed on top of the plastic block 5-2, and the The aluminum block 5-1 is connected with the piston rod 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com