Automatic intelligent warehousing logistics equipment

An intelligent warehousing and logistics technology, applied in the field of logistics, can solve problems such as deformation, and achieve the effect of convenient classification and high loading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

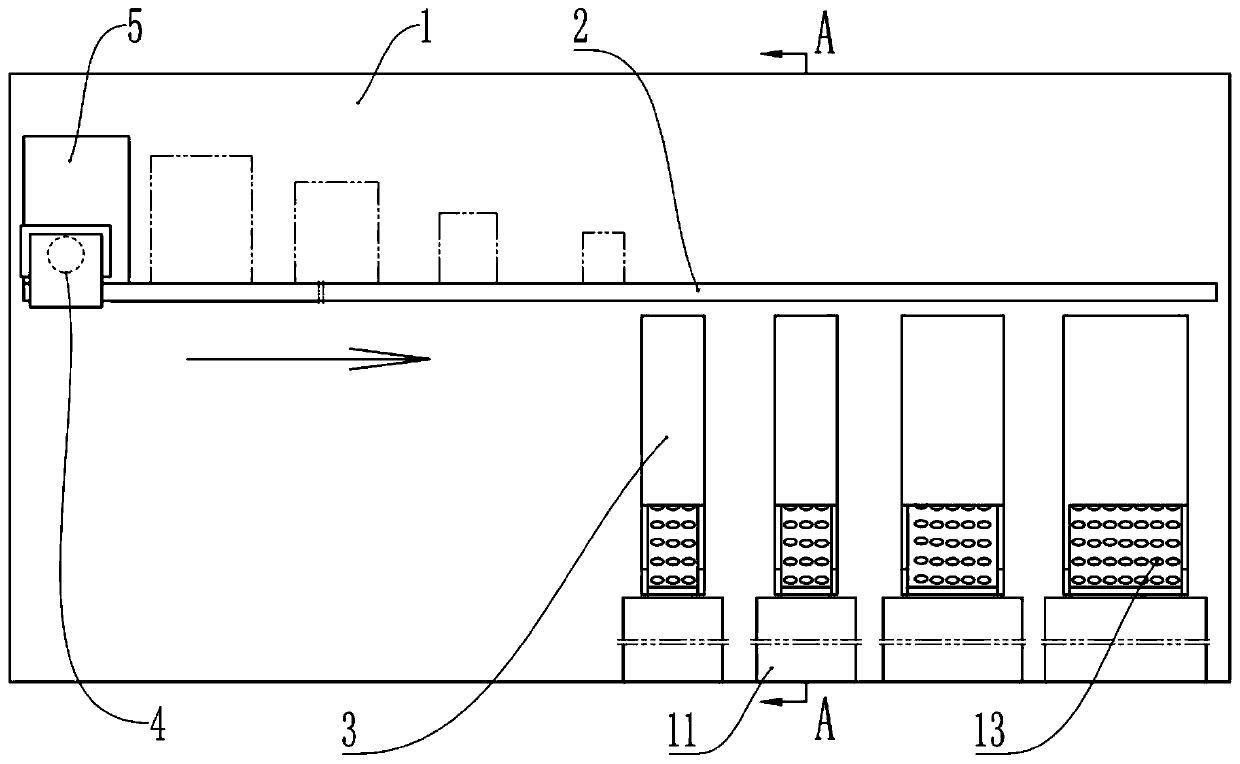

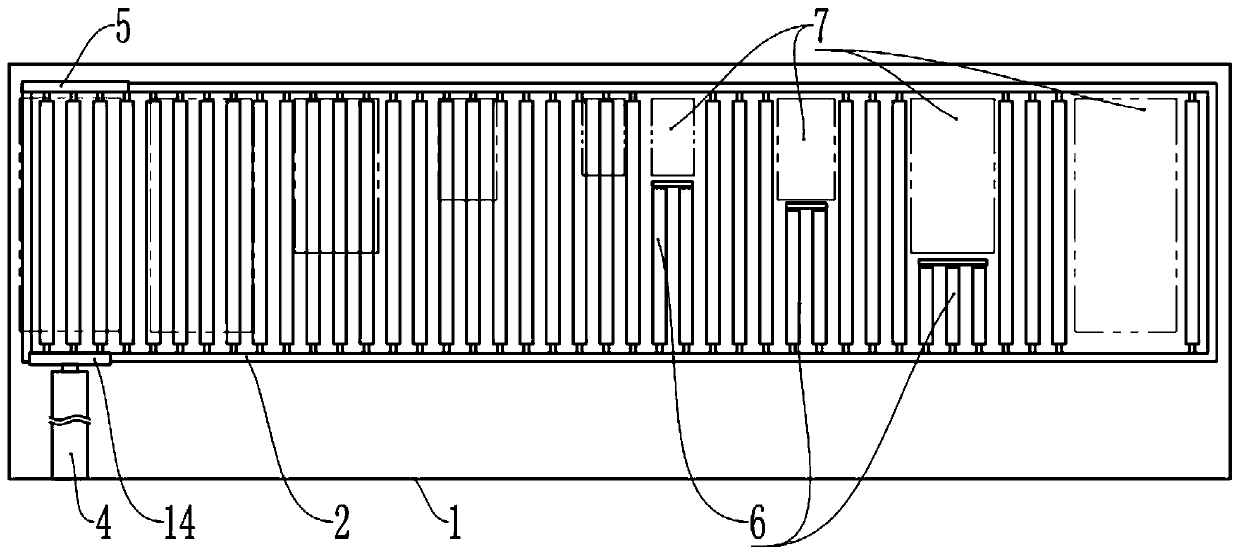

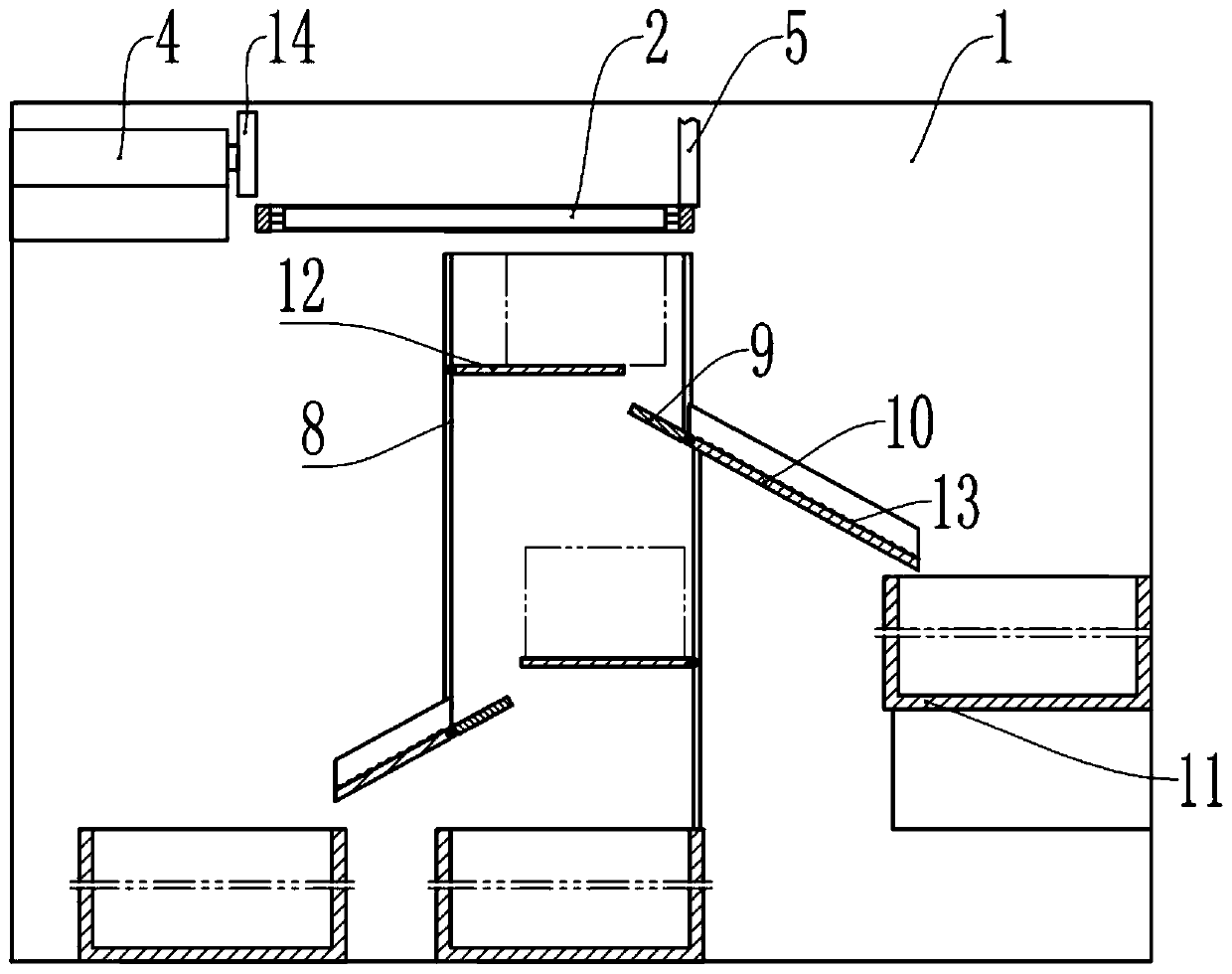

[0035] Embodiment one is basically as attached Figure 1 to Figure 3 Shown:

[0036] combine figure 1 , automated intelligent warehousing and logistics equipment, including a frame 1 and a roller conveyor line 2 installed on the frame 1, a sorting mechanism 3 and an alignment mechanism 4, the roller conveyor line 2 is a powered roller conveyor line, and the sorting mechanism 3 is located at Below the roller conveyor line 2, a baffle plate 5 is connected to the roller conveyor line 2 by bolts. The baffle plate 5 and the alignment mechanism 4 are located on both sides of the roller conveyor line 2 in the width direction. The transmission direction of the roller conveyor line 2 is from left to right. .

[0037] combine figure 2 , a movable roller 6 is installed on the roller conveying line 2, one end of the movable roller 6 is connected with the roller conveying line 2, and the other end of the movable roller 6 is rotatably connected to the frame 1, and the movable roller 6 a...

Embodiment 2

[0046] Embodiment two is basically as attached Figure 4 and Figure 5 As shown, Embodiment 2 is improved on the basis of Embodiment 1. Three adjustment mechanisms 15 are added to the automated intelligent storage and logistics equipment. The three adjustment mechanisms 15 all include adjustment plates 16 and drive the adjustment plates 16 to move horizontally. The cylinder, the piston rod end of the cylinder is threadedly connected with the adjusting plate 16, and the moving direction of the adjusting plate 16 is perpendicular to the conveying direction of the roller conveying line 2.

[0047] The interval between the adjacent adjusting plates 16 and the interval between the push plate 14 and the leftmost adjusting plate 16; the cylinder drives the moving distance of the adjusting plates 16 to decrease successively from left to right, and the height of the adjusting plates 16 is along the length of the conveying mechanism. The conveying direction decreases successively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com