Shaping sorting machine for recycling wine bottle

A sorting machine and wine bottle technology, which is applied in the field of tableware, can solve the problems of inaccurate classification and low work efficiency, and achieves the effect of high work efficiency and preventing mutual stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

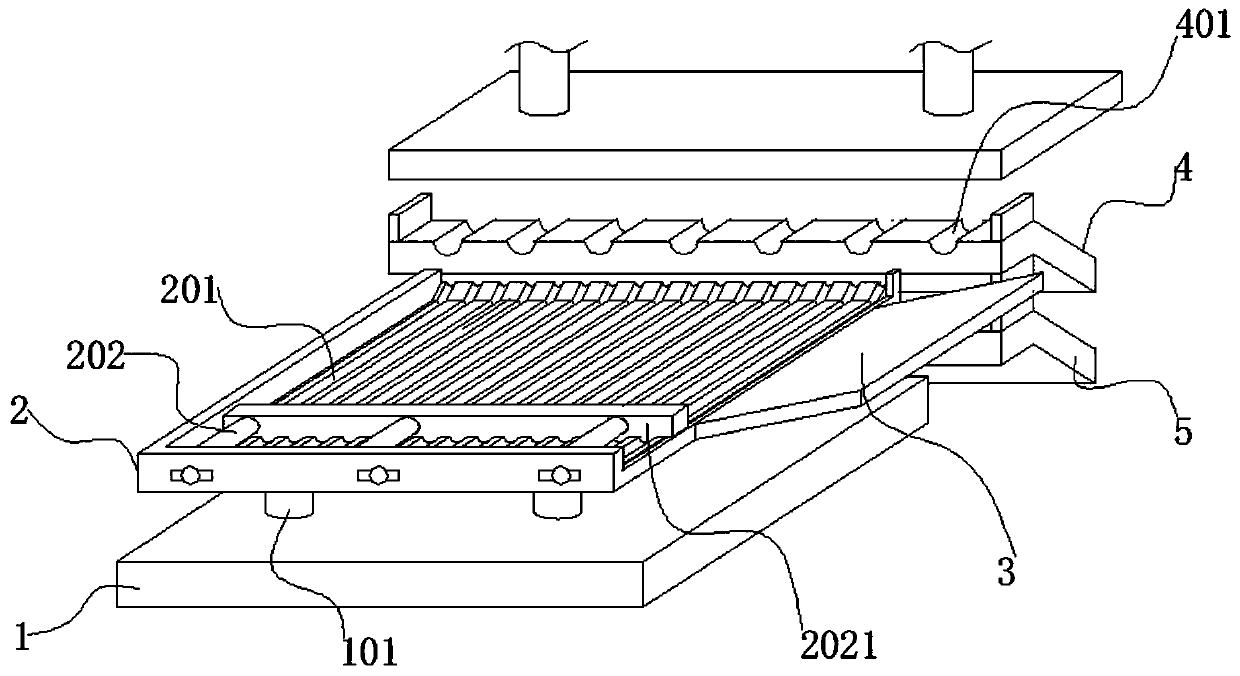

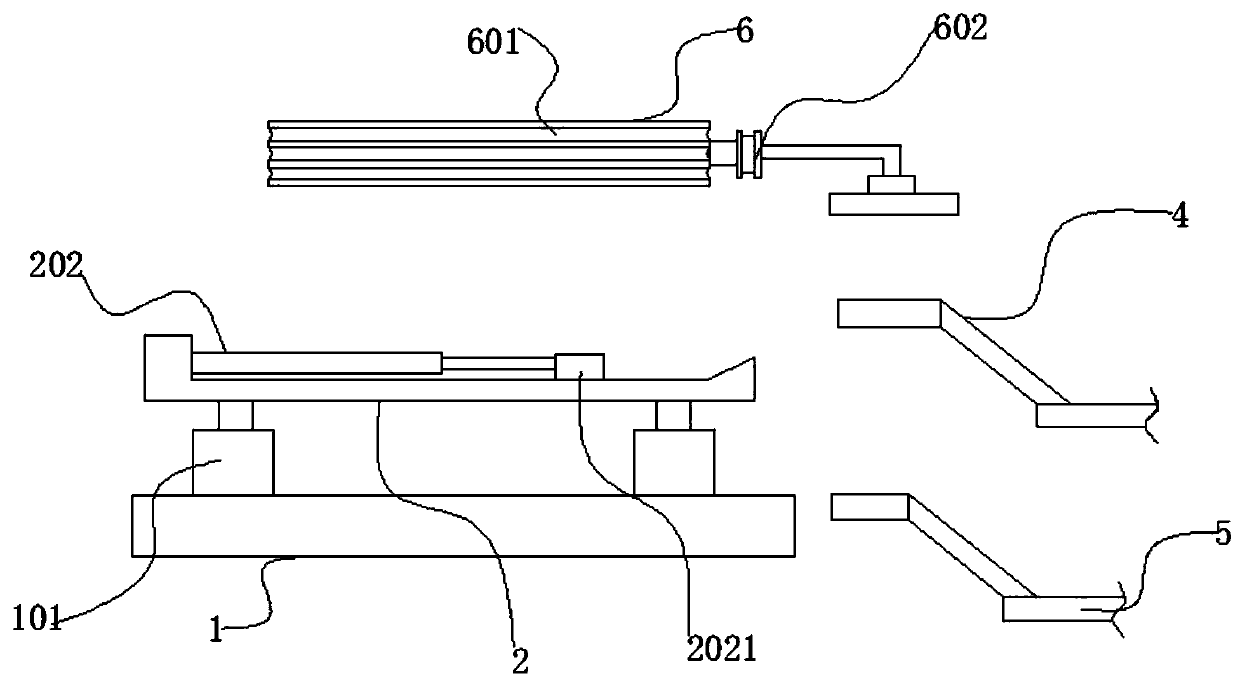

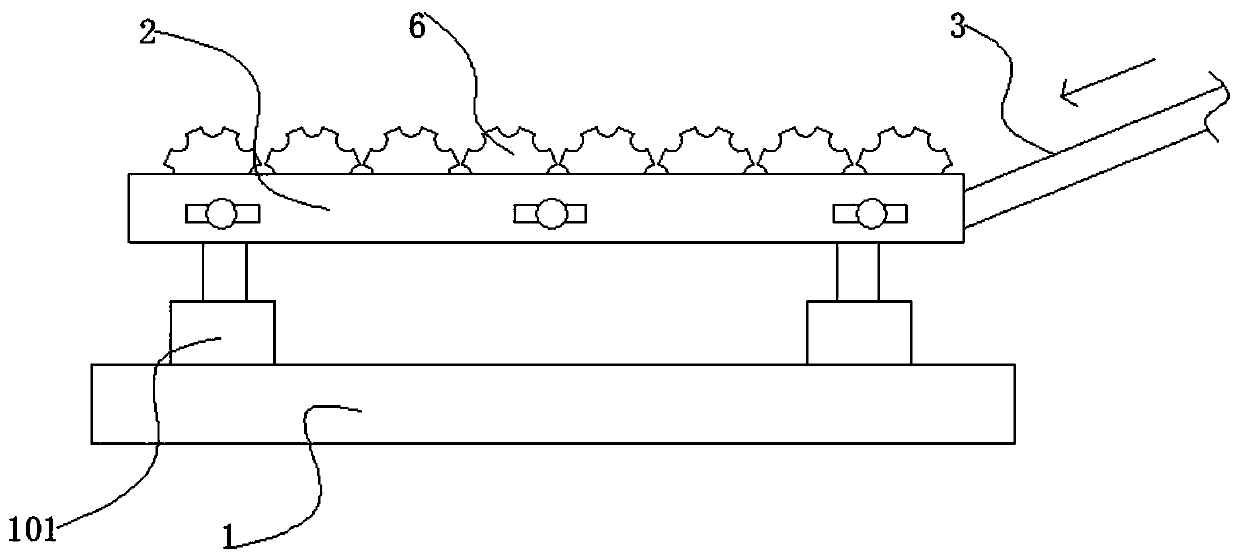

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The invention provides a shaping and sorting machine for wine bottle recovery, which comprises a bottom plate 1, an open plate 2, a feeding plate 3, a first guide plate 4, a second guide plate 5, Positioning roller 6, longitudinal lifting cylinder 101, placement groove 201, horizontal pushing cylinder 202, pushing plate 2021, diversion groove 401, positioning groove 601, belt roller 602 and drive motor 603; bottom plate 1 is fixedly connected with longitudinal lifting cylinder 101 , the top of the longitudinal lift cylinder 101 is fixedly connected with the open plate 2, the outside of the top of the open plate 2 is rotatably connected with the positioning roller 6 through the connecting piece, the surface of the positioning roller 6 is integrally provided with a positioning groove 601, and the other side of the positioning roller 6 is integrally provided There is a belt roller 602, a feed plate 3 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com