A chip reservoir and its manufacturing method

A production method and reservoir technology, applied in chemical instruments and methods, earth square drilling, preparation of test samples, etc., can solve the problems of not having the characteristics of real reservoirs, ignoring, restricting the research and development of experimental authenticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for making an oil reservoir on a chip, comprising:

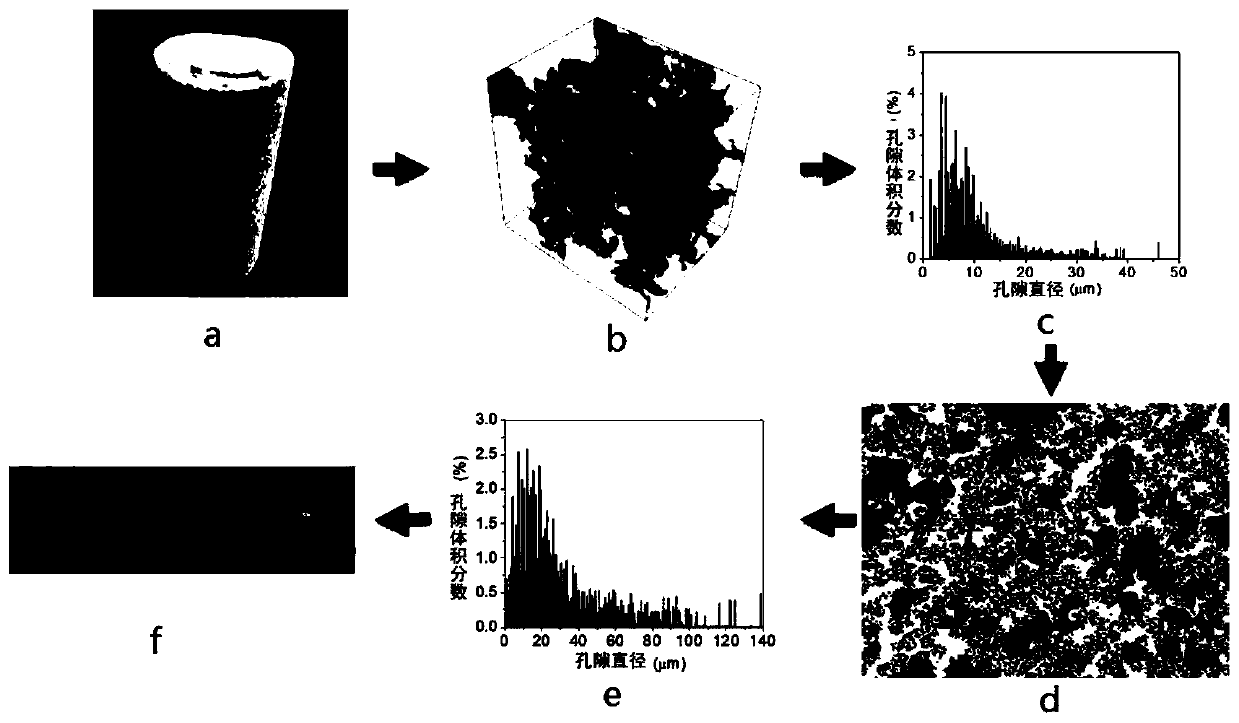

[0056] (1) Select real reservoir cores (sandstone, such as figure 1 shown in a), and use micro-CT to scan the three-dimensional structure of the real reservoir core (such as figure 1 shown in b);

[0057] (2) Use matlab or imageJ software to reconstruct the three-dimensional structure of the real reservoir core obtained by scanning, and use the maximum sphere method to extract pore size distribution characteristics (such as figure 1 Shown in c, the abscissa is the pore diameter μm, and the ordinate is the pore volume fraction %);

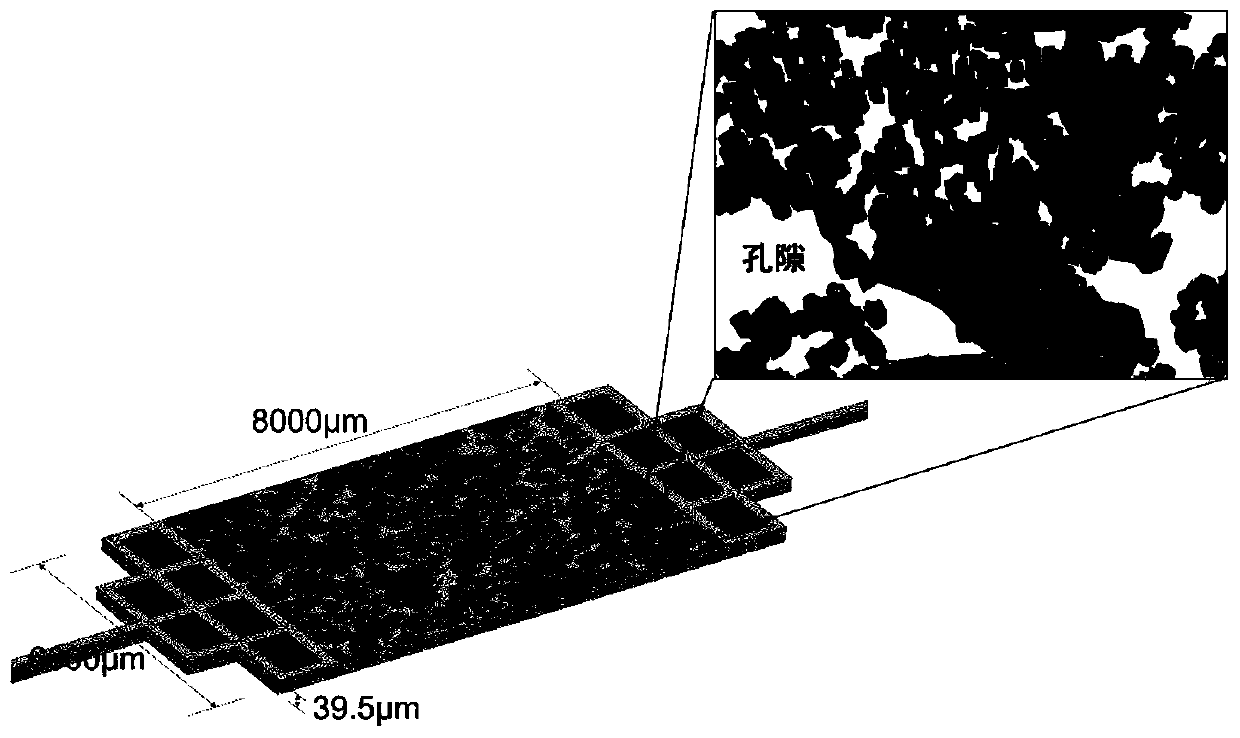

[0058] (3) According to the obtained pore size distribution characteristics, the formation of the pore structure of the real oil reservoir core and the accumulation form of rock particles are analyzed, and the main large particles (referring to volume accounting for the entire rock solid matrix) in the rock particles are extracted. Particles whose volume is more than 1% of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com