Synthesis method of ZnO@SiO2 supported mesoporous niobium phosphate catalyst and application thereof in preparation of 5-hydroxymethylfurfural

A technology of niobium phosphate catalyst and hydroxymethyl furfural, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problem of low yield of 5-hydroxymethyl furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: A ZnO@SiO 2 The synthetic method of supported mesoporous niobium phosphate catalyst comprises the following steps:

[0022] (1) Preparation of nano-zinc oxide: Accurately weigh 2.195g of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O), and it was uniformly dissolved in 100mL CH 3 CH 2OH, and fully stirred at 65°C for 20min to obtain a homogeneous solution; then take sodium hydroxide (0.4g) and dissolve it in 100mLCH 3 CH 2 OH, and fully dissolved at 50°C; the Zn(CH 3 COO) 2 2H 2 The O solution was cooled to 50°C, and 5 mL of polyethylene glycol 200 (PEG200) was added. After stirring for 10 min, the sodium hydroxide ethanol solution was quickly added to the Zn(CH 3 COO) 2 2H 2 In the O solution, the nanometer zinc oxide solution is obtained after reacting for 10 minutes;

[0023] (2) ZnO@SiO 2 Preparation of core-shell quantum dots: Accurately take 200 μL of concentrated ammonia water and 100 mL of absolute ethanol, and mix them evenly to obtain NH...

Embodiment 2

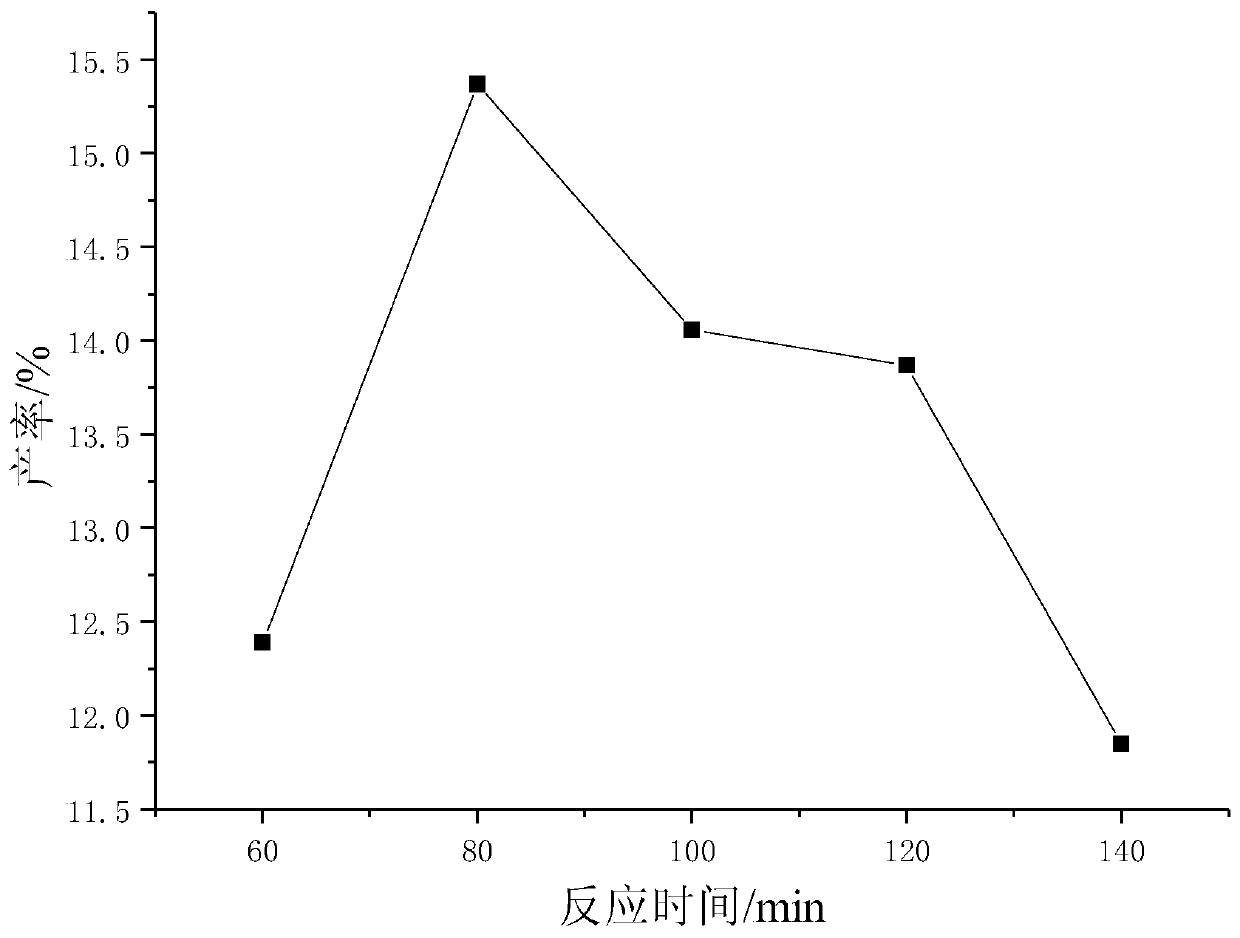

[0027] Embodiment 2: a kind of ZnO@SiO as described in embodiment 1 2 The application of the supported mesoporous niobium phosphate catalyst in the preparation of 5-hydroxymethylfurfural, weigh 0.04g glucose and place it in a 50mL beaker and add 20mL water to ultrasonically dissolve it completely. Add γ-valerolactone and glucose solution at a ratio of 1:9, stir evenly and add crushed ZnO@SiO 2 Load mesoporous niobium phosphate catalyst, the mass ratio of catalyst to glucose is: 120:0.24, then place the round-bottomed flask in a heater with a temperature of 140°C, install a condensing reflux device and pass tap water, and carry out heating and reflux reaction for 80 minutes. After taking out the reaction flask, filter it with a suction filter bottle while it is hot, and the liquid obtained by suction filtration is 5-hydroxymethylfurfural solution, and the yield is 84.96%.

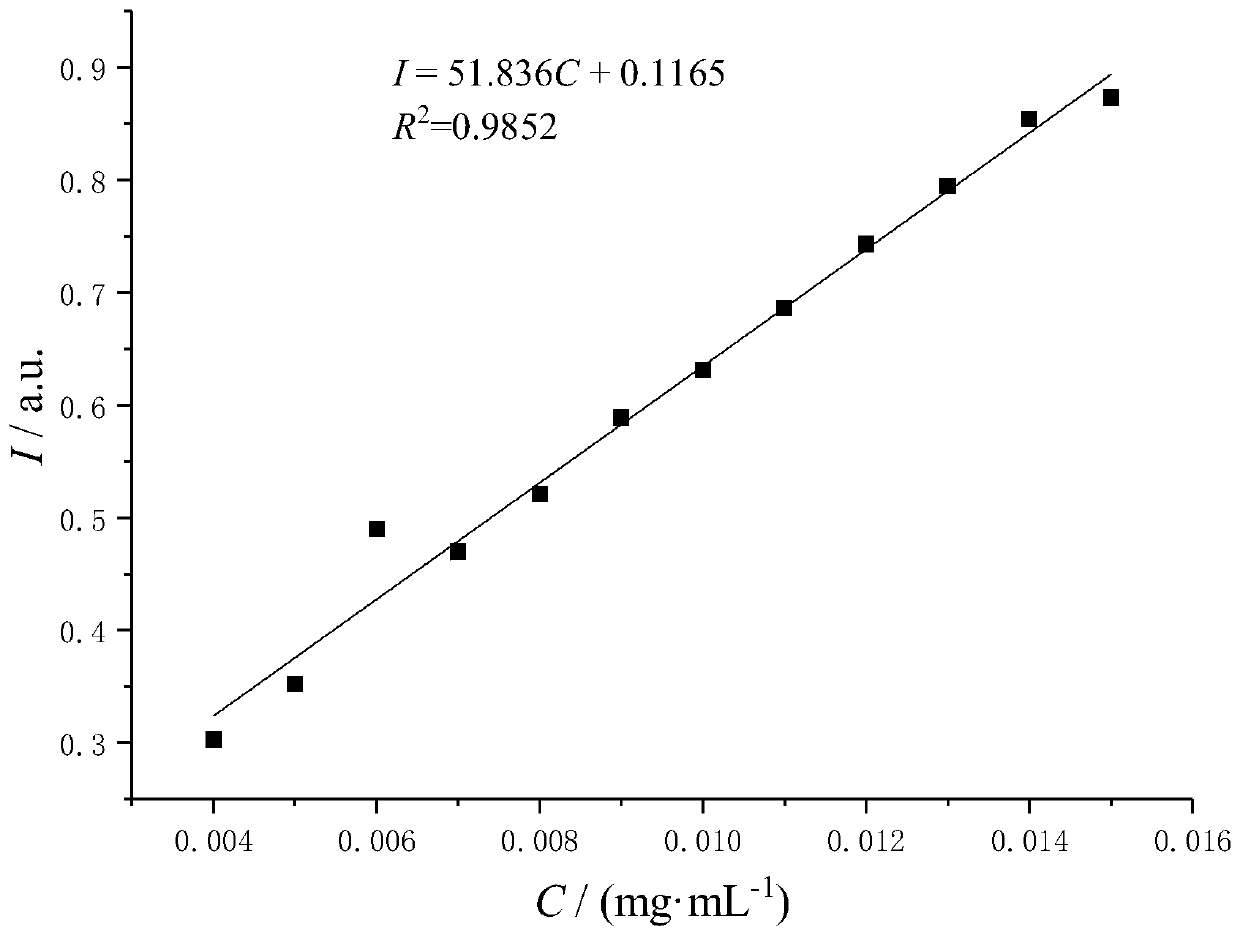

[0028] The calculation of the detection and yield of product 5-hydroxymethylfurfural is as follows:

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap