Method for preparing full-thickness skin tissue engineering scaffold with gradient pore structure

A technology for tissue engineering scaffolds and full-thickness skin, applied in additive processing, medical science, prostheses, etc., can solve the problems of difficult to meet the requirements of multi-layer complex structures, difficult to achieve precise control of pore structure and personalized customization, etc. Achieve the effects of promoting vascularization and proliferation of fibroblasts, accelerating wound healing, and combining tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

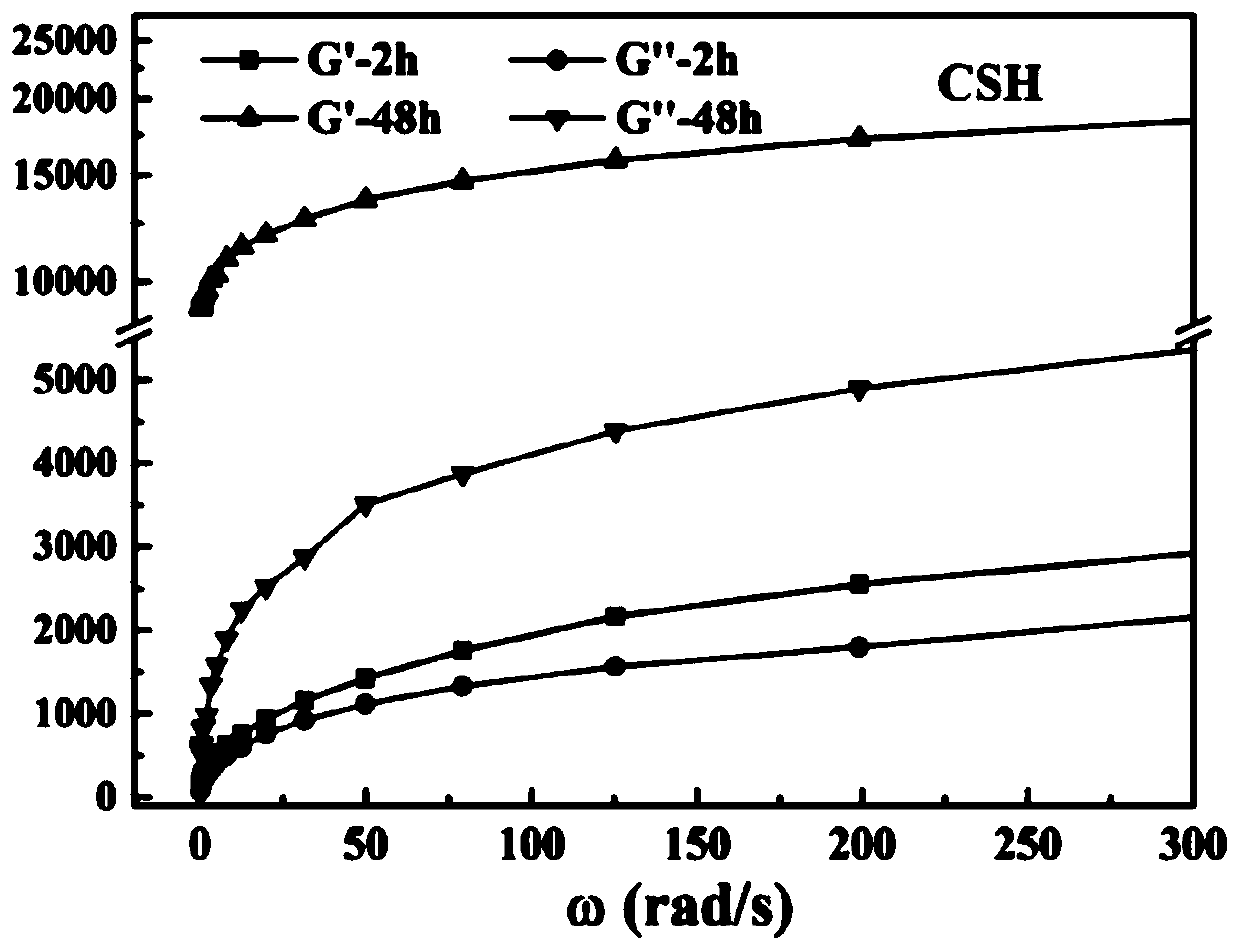

[0034] The full-thickness skin tissue engineering scaffold with gradient pore structure prepared in this example has two layers, namely the epidermis and the dermis, wherein the epidermis is made of chitosan / silica gel, i.e. CS- Si gel is made, and the dermis is made of chitosan / silicon dioxide / gelatin gel, that is, CS-Si-Gel gel is made; the preparation process of the support is as follows:

[0035] Chitosan-silica hybrid (CS-Si) gel preparation: 8g chitosan was dissolved in 4% acetic acid aqueous solution to prepare 8wt% chitosan solution; 2 TEOS solution, stirred to make it evenly mixed, the obtained sol was transferred to a barrel, and after defoaming, it was placed at room temperature for 48 hours to gel.

[0036] Gelatin-chitosan-silica hybrid (10Gel-CS-Si) gel preparation: 1.2g gelatin (Gel) was added into deionized water to prepare a concentration of 10wt% gelatin solution A, and 0.12g GPTMS was added to the above solution , stirred vigorously for 2h under 50°C water ba...

Embodiment 2

[0041] The preparation process of the full-thickness skin tissue engineering scaffold with gradient pore structure in this embodiment is as follows:

[0042] Chitosan-silica hybrid (CS-Si) gel preparation: 12g chitosan was dissolved in 10% acetic acid aqueous solution to prepare 12wt% chitosan solution; 2 TEOS solution, stirred to make it evenly mixed, the obtained sol was transferred to a barrel, and after defoaming, it was placed at room temperature for 48 hours to gel.

[0043] Gelatin-chitosan-silica hybrid (20Gel-CS-Si) gel preparation: 2g gelatin (Gel) was added to 8g deionized water to prepare a concentration of 20wt% gelatin solution A, and 0.2g was added to the above solution GPTMS, stirred vigorously in a water bath at 50°C for 2 hours; weighed 12g of chitosan (CS) and dispersed it in deionized water to prepare 8wt% chitosan suspension B; weighed TEOS solution and dissolved it in an acidic deionized In the aqueous solution, the TEOS hydrolyzate C was prepared.

[0...

Embodiment 3

[0048] The preparation process of the full-thickness skin tissue engineering scaffold with gradient pore structure in this embodiment is as follows:

[0049] Chitosan-silica hybrid (CS-Si) gel preparation: 8g chitosan is dissolved in 4% acetic acid aqueous solution and prepares the chitosan solution of 8wt%; Add the TEOS solution of pre-hydrolysis, stir to make it Mix evenly, transfer the resulting sol into a barrel, remove the bubbles and let it gel at room temperature for 2 hours.

[0050] Gelatin-chitosan-silica hybrid (10Gel-CS-Si) gel preparation: 2g gelatin (Gel) was added into deionized water to prepare a concentration of 10wt% gelatin solution A, and 0.6g GPTMS was added to the above solution, Stir vigorously in a water bath at 50°C for 2 hours; weigh 12g of chitosan (CS) and disperse it in deionized water to prepare 8wt% chitosan suspension B; measure TEOS solution and dissolve it in an acidic deionized aqueous solution with a pH value of 2 , to prepare TEOS hydrolyz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com