Mixed flow production line dynamic bottleneck prediction method

A forecasting method and production line technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as inaccurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

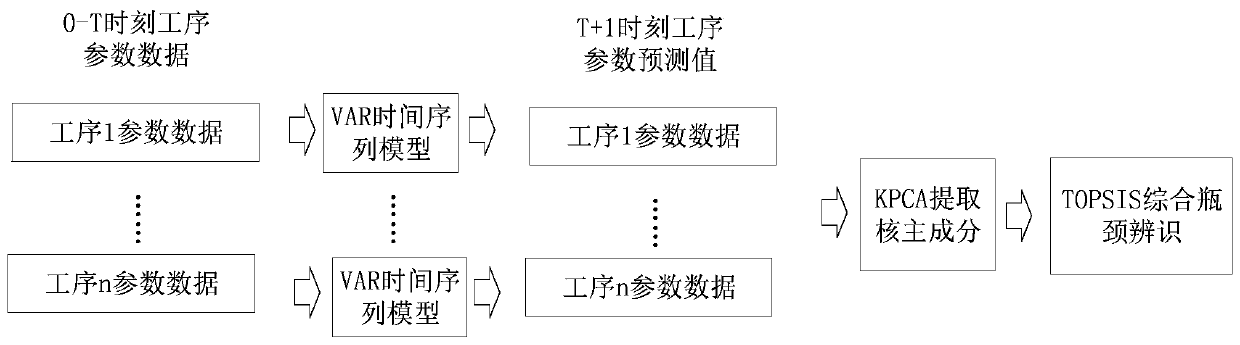

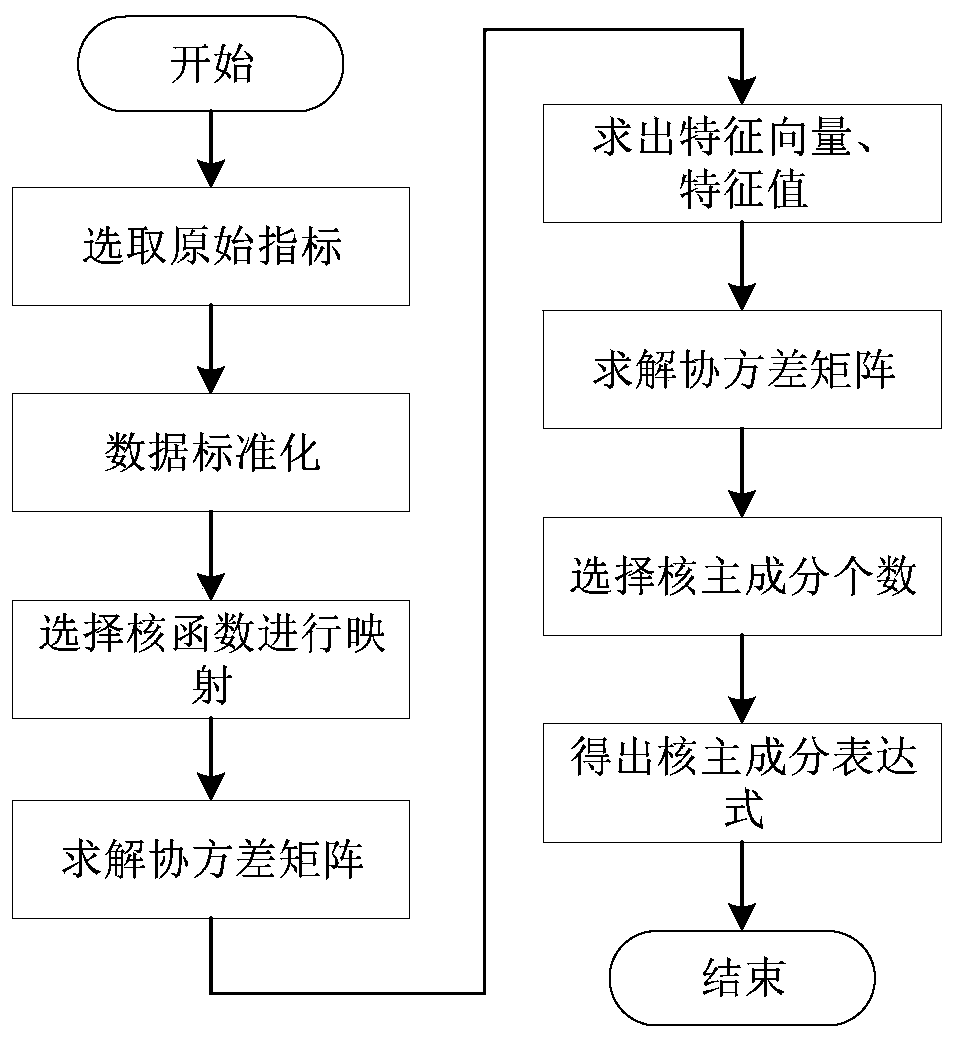

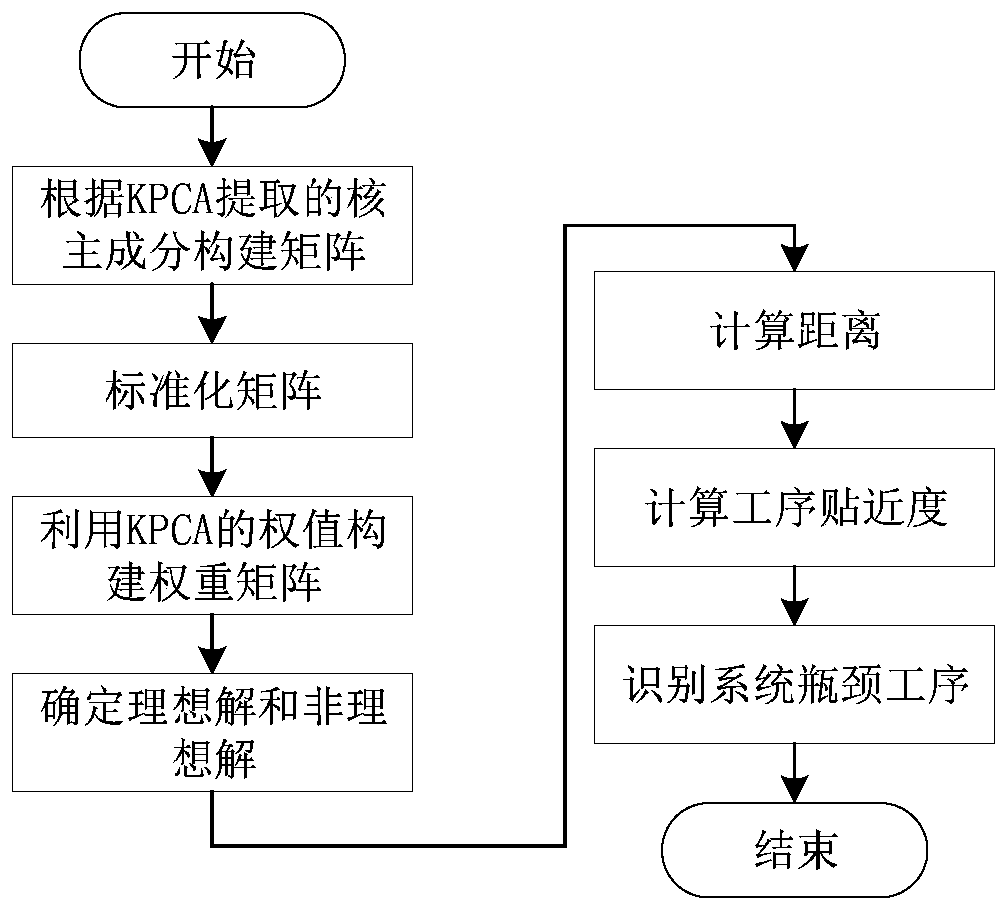

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation manners and accompanying drawings.

[0078] by Figure 4 The lower vehicle body assembly line described in is taken as an example to analyze the method adopted in the present invention. There are 10 processes in total. For the convenience of discussion, the letters in the block diagram are used to represent the processes.

[0079] The production line now mainly produces three products, C2, S1, and C1, in mixed flow. Table 1 shows the timetable required for each product in each production process, and the production line beat is 70S.

[0080] Table 1 Production schedule of each process of the product

[0081] car model A B C D E F G H I J C2 65 62 65 64 65 70 66 65 64 64 S1 63 62 65 66 63 69 66 65 63 64 C1 65 64 65 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com