Generation method of non-standard wedge and accessory standard part thereof

A technology of wedge and standard parts, applied in the field of intelligent mold design and manufacturing, can solve the problems of high work repeatability and low design efficiency, achieve the effect of high speed and efficiency, improve design efficiency, and eliminate repetitive labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

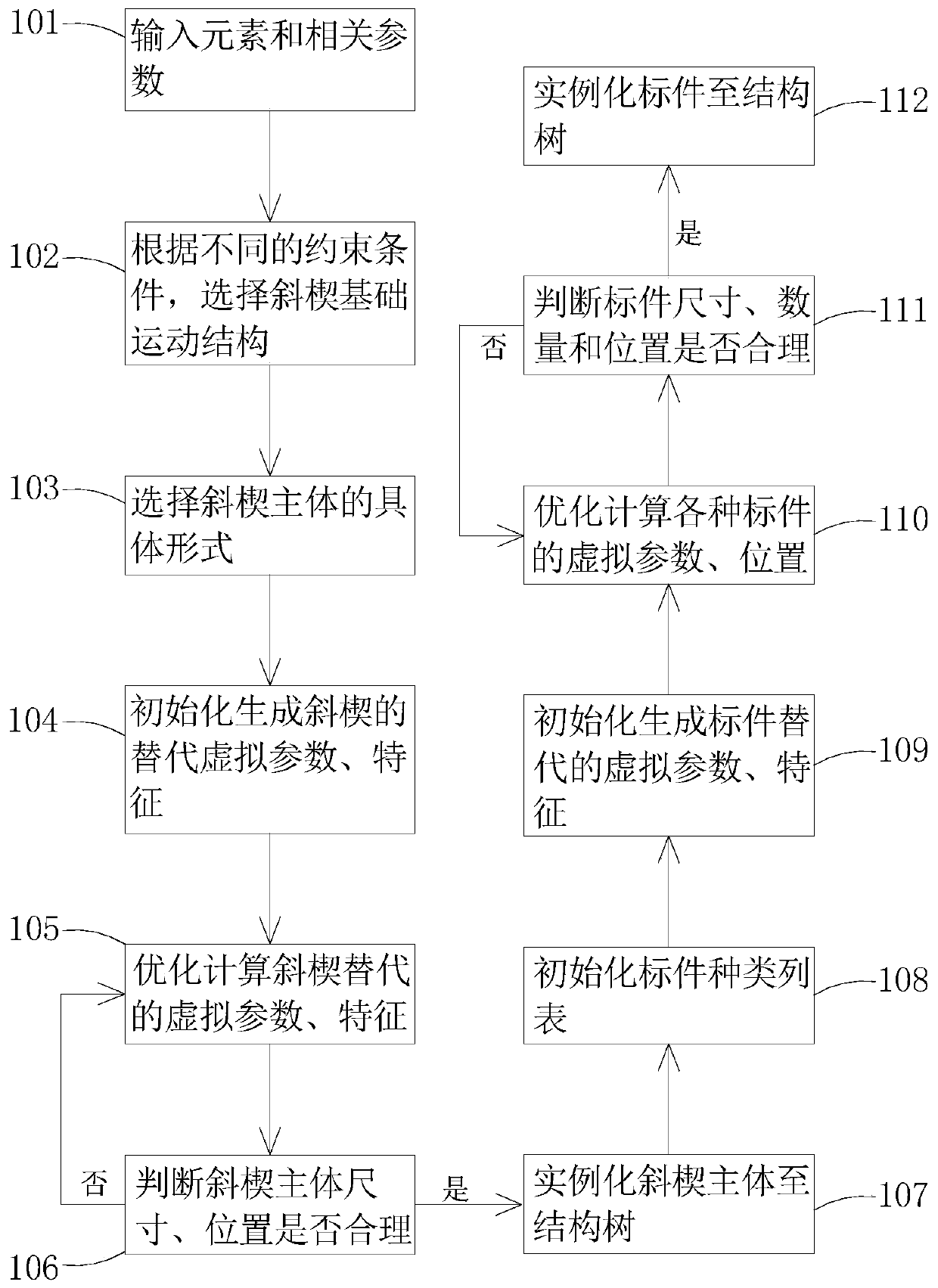

[0028] Below in conjunction with accompanying drawing, invention is described in further detail.

[0029] figure 1 A schematic flowchart of a method for generating a non-standard wedge and its associated standard parts according to an embodiment of the present invention is schematically shown.

[0030] refer to figure 1 , a method for generating a non-standard wedge and its associated standard parts includes the following steps:

[0031] Step 101: Input elements and related parameters; said elements and related parameters include: working line set (WCurve_Sets), working axis system (Axis_Sets), insert frame (SCurve_Sets), process product (Product), etc.

[0032] Step 102: Select the kinematic structure of the wedge foundation according to different constraints; the constraints are, for example: whether the product has a negative angle. The naive Yebes algorithm is used to select the motion structure of the wedge foundation. The motion structure of the wedge foundation inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com