Ultra-large type offshore floating type platform and butt joint forming method thereof

A floating platform, ultra-large technology, applied in the direction of floating buildings, etc., can solve problems such as difficult to guarantee safety and reliability, complex structure, etc., to achieve high safety and reliability, good effect in harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

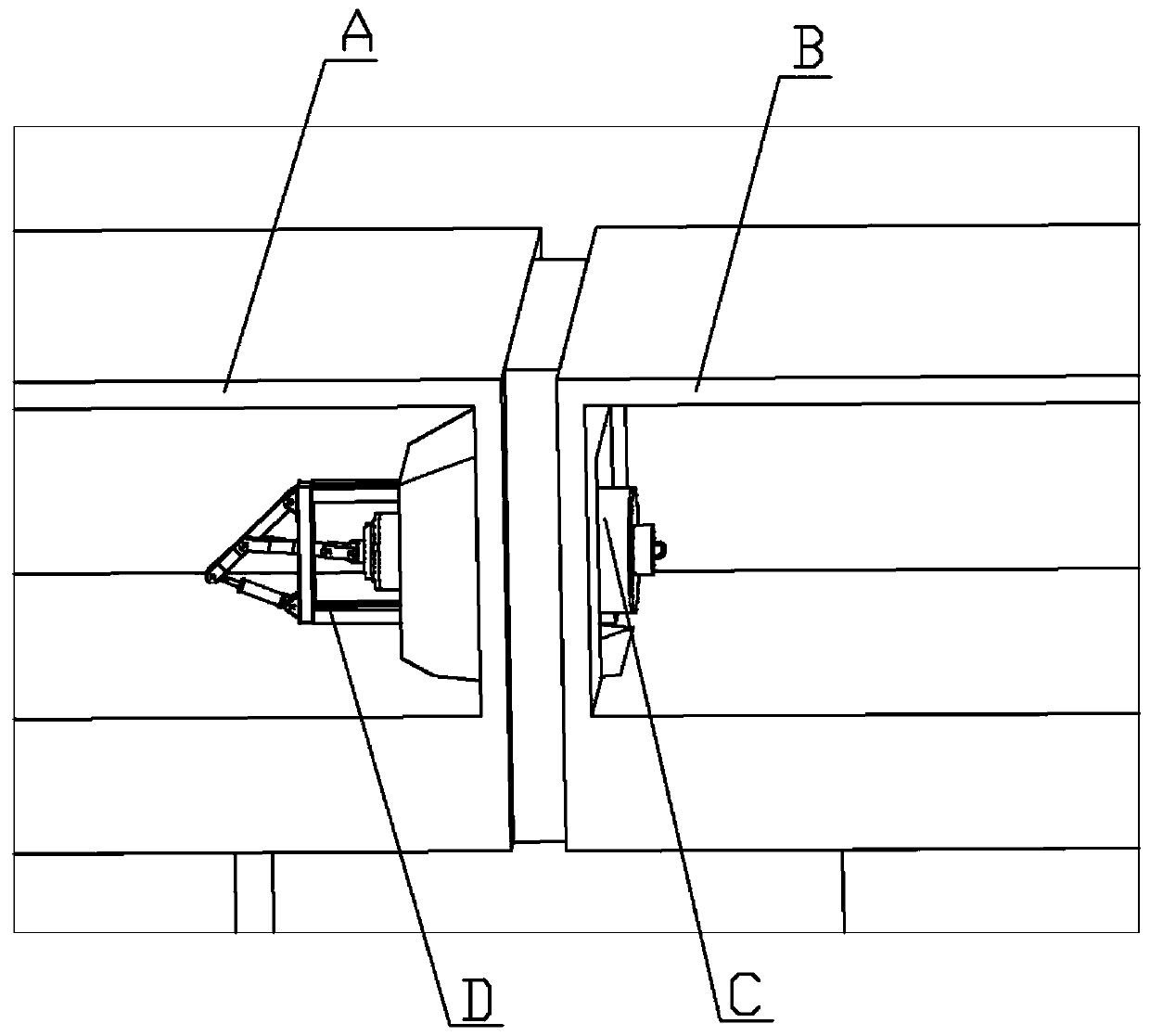

[0041] The ultra-large offshore floating platform disclosed in this embodiment includes several floating body units, and adjacent floating body units are connected by connectors. figure 1 A schematic diagram of the connection and assembly of the adjacent floating body unit A and floating body unit B is shown in . From figure 1 It can be seen that the floating body unit A and the floating body unit B are connected by a connector C, and the pretensioning device D is connected to one end of the connection C.

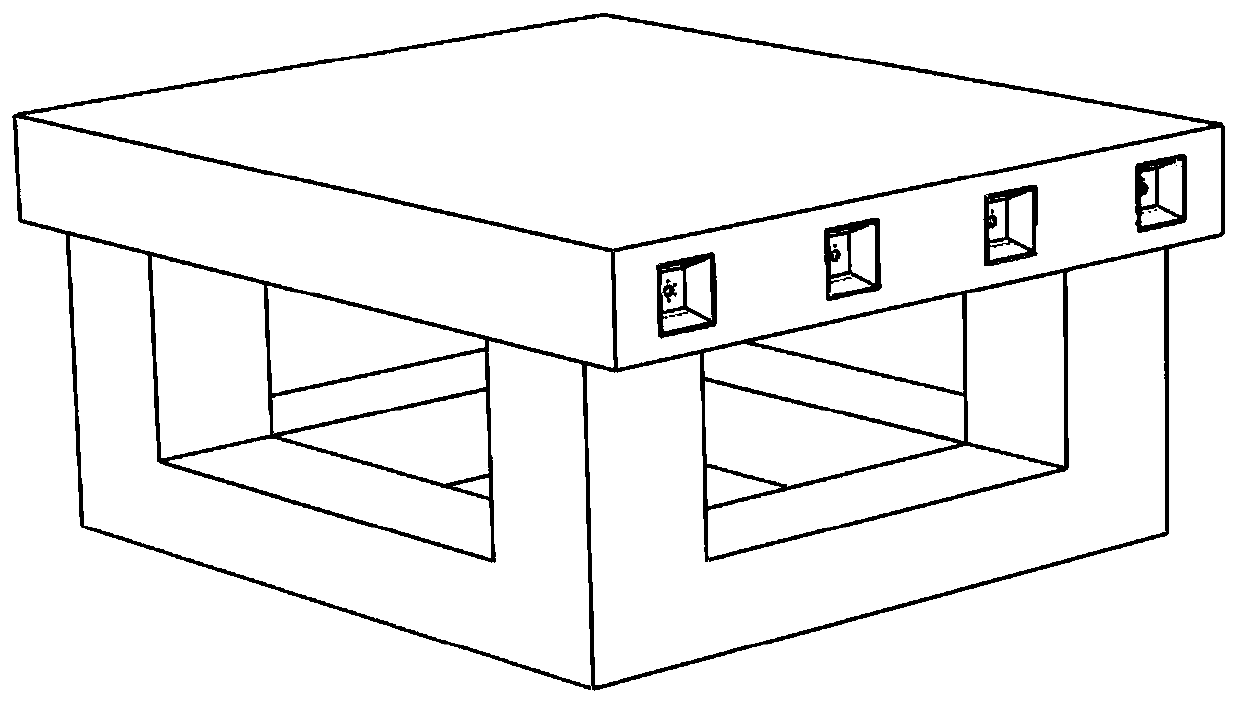

[0042] Such as figure 2 As shown, the side edge of the floating body unit A has a plurality of inwardly extending bosses, and the shape of the inwardly extending bosses is a square truss.

[0043] Such as image 3 As shown, the side edge of the buoyant unit B has the same number of protruding bosses, and the shape and size of the protruding bosses match the inner cavity of the inner protruding bosses.

[0044] Such as figure 1 and Figure 4 As shown, the buoyant unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com