Tobacco leaf storage container with function of aroma enhancement and method for aroma enhancement of tobacco leaves

A technology for storing containers and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of limited amount of shredded tobacco, laborious and laborious filling of shredded tobacco, and high work intensity, so as to achieve consistent flavor enhancement, avoid impurity removal procedures, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

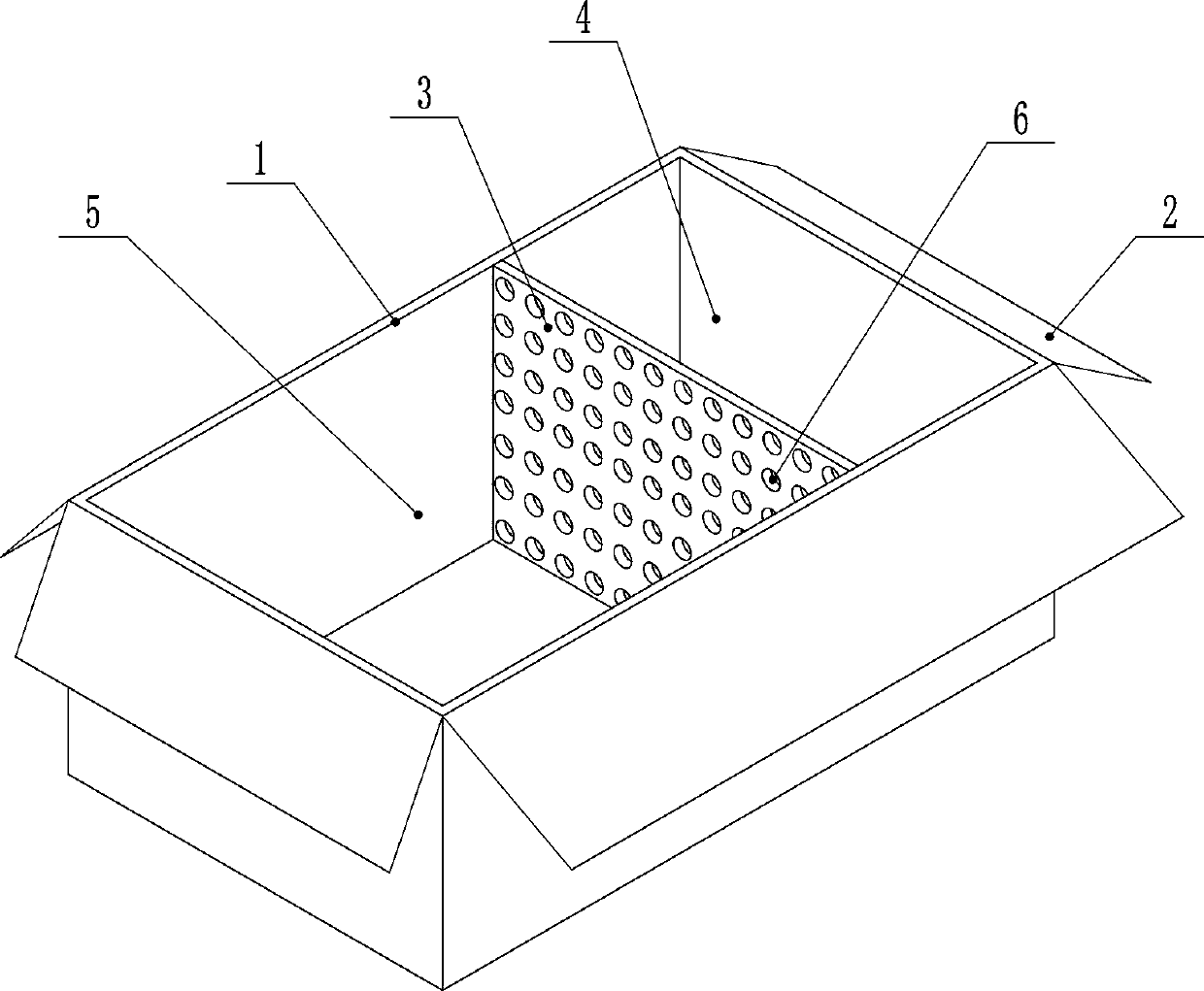

[0039] like figure 1 As shown, a tobacco leaf storage container with flavoring function, the container is a carton structure, including a container main body 1, a container cover plate 2, and a partition 3 arranged in the container main body 1, and the partition 3 separates the The inner space of the container main body 1 is divided into a fragrance area 4 and a tobacco leaf storage area 5, and the partition board 3 is provided with an aroma diffuser hole 6, and the space between the spice area 4 and the tobacco leaf storage area 5 passes through the aroma diffuser hole 6 connections, where the thickness of the partition is 2mm, and the distribution area of the fragrance holes is 30mm 2 , the shape of the fragrance-diffusing hole is not limited, and can be one or more of conventional circles, triangles, quadrangles or other conventional shapes.

[0040] In this embodiment, flue-cured tobacco, oriental tobacco or burley tobacco is selected as the sheet tobacco, and the spice...

Embodiment 2

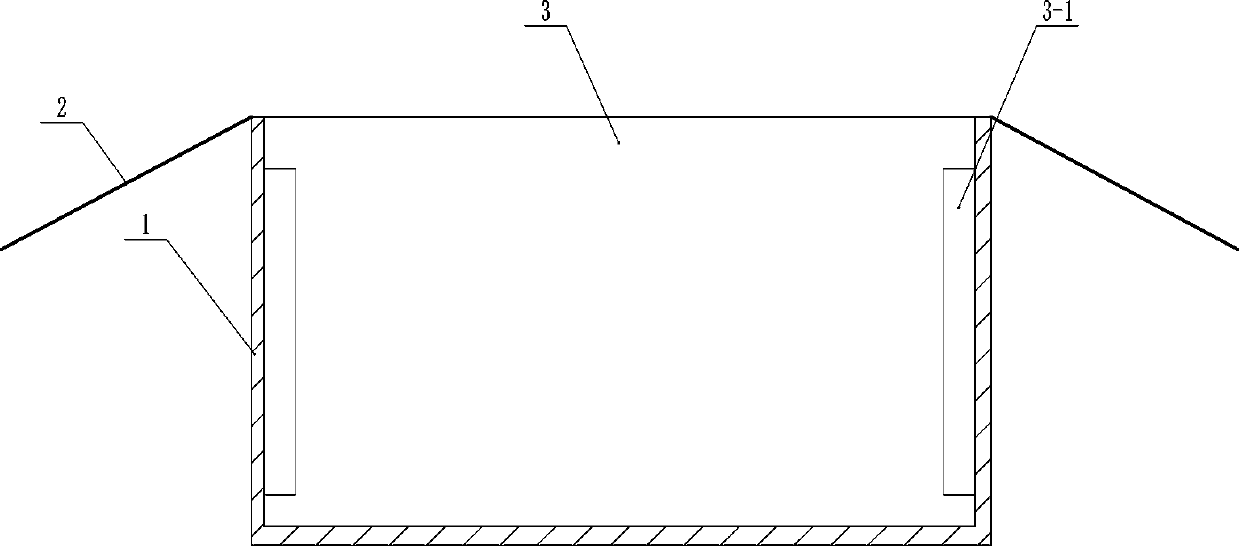

[0044] like figure 2As shown, the main difference between this embodiment and Embodiment 1 is that: at least one end of the partition 3 forms a channel 3-1 with the side wall of the container body 1 or the inside of the container cover, and the spice area and the The spaces in the tobacco leaf storage area are communicated through the passage.

[0045] The advantage is that the insulation is better, and the gas circulation is realized through the side, avoiding excessive contact in the middle, and the insulation effect is better.

Embodiment 3

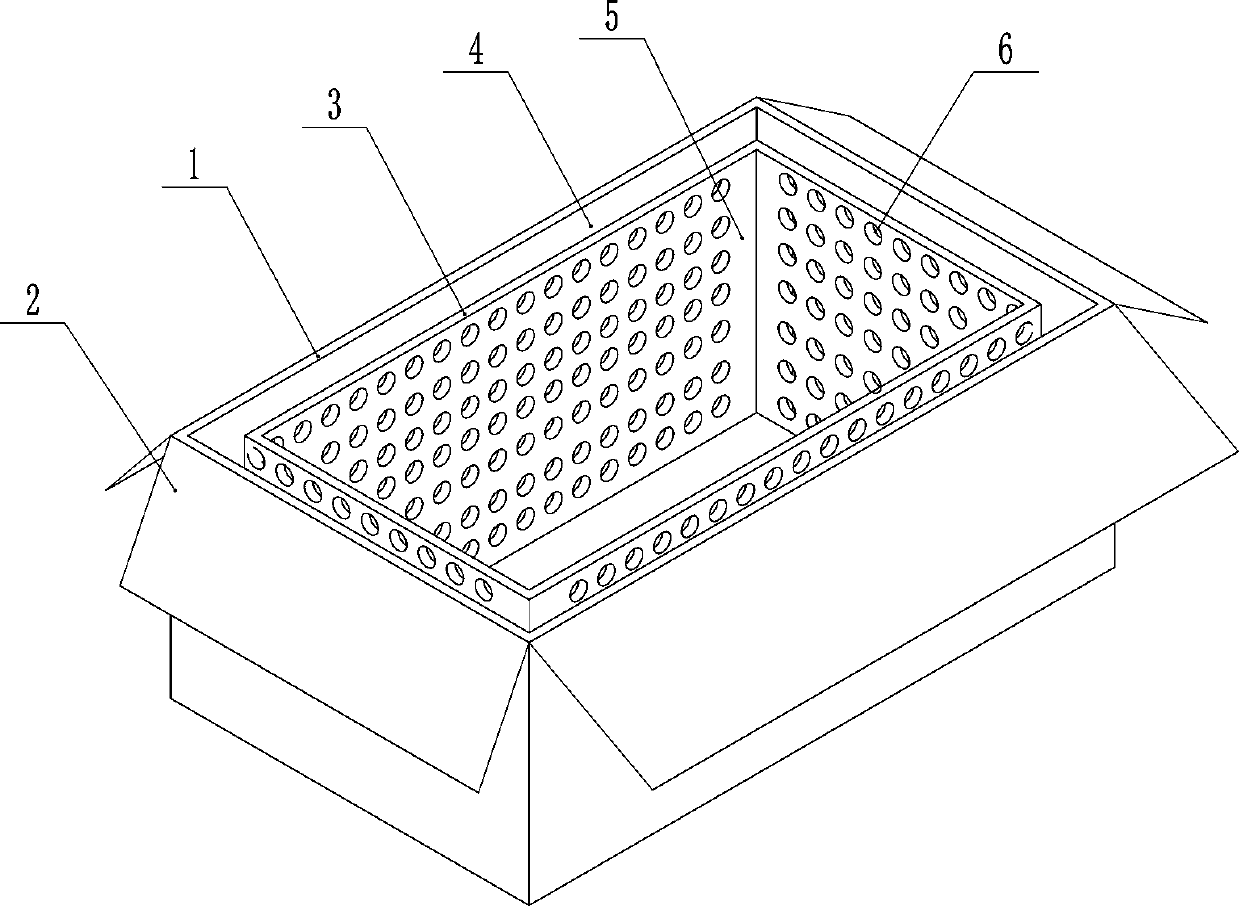

[0047] like image 3 As shown, the main difference between this embodiment and Embodiments 1 and 2 is that: the partition 3 is arranged along the side wall of the container body 1, and the partition 3 and the side wall of the container body 1 are formed The tobacco leaf storage area 5 is formed in the area enclosed by the fragrance area 4 and the partition plate 3 .

[0048] Under this structure, the fragrance surrounds the cigarette from all sides, the distribution uniformity of the aroma is improved, the density is also increased correspondingly, and the aroma distribution in the tobacco leaves is more uniform. Compared with the structure of Embodiment 1 or 2, a certain amount of time can be saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com