Gunpowder tea roasting machine

A technology for frying and drying machine and pearl tea, which is applied in tea processing before extraction, mechanical oscillation control, instruments, etc. It can solve the problems of inconvenient operation, limit swing selectivity, limit adaptability, etc., and improve stability and quality. , The effect of improving the shaping efficiency and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

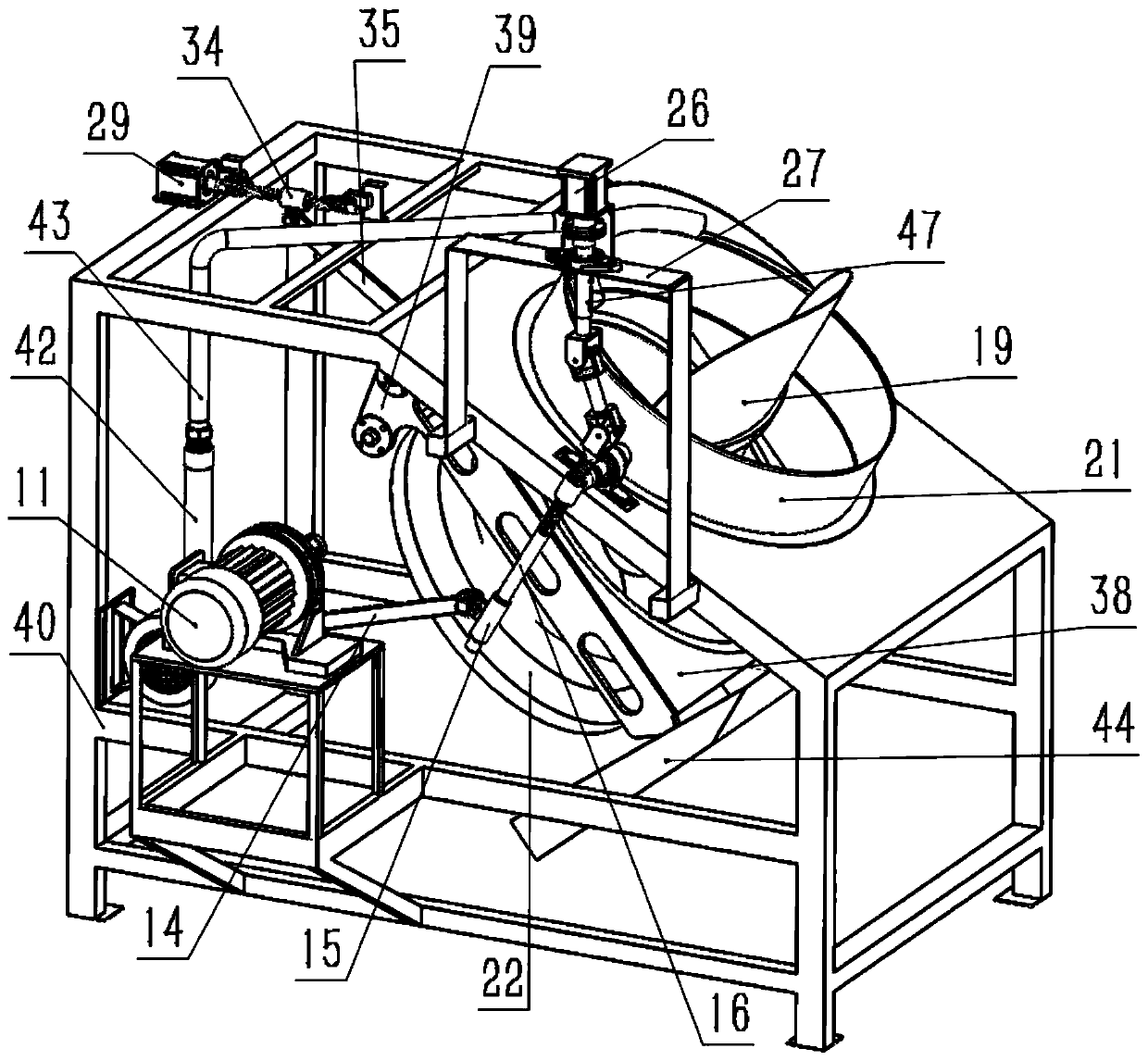

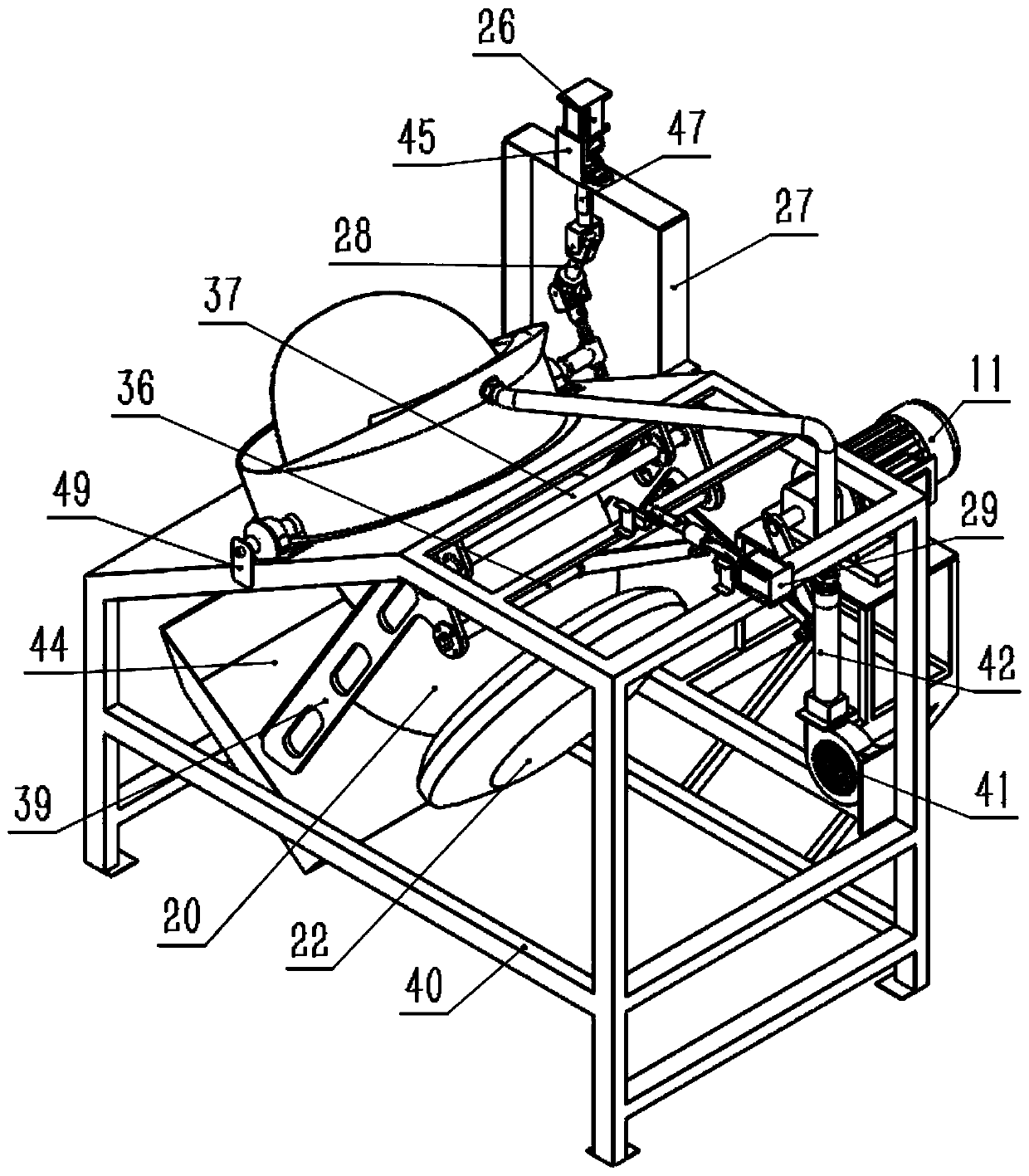

[0038] Such as figure 1 , 2 As shown: the present invention includes a transmission assembly, a tea frying assembly, a swing adjustment assembly, a tea delivery assembly, a hot air assembly and a PLC control unit.

[0039] Described transmission mechanism comprises decelerating motor 11, decelerating motor bearing 12, crank 13, transmission connecting rod 14, transmission rocker sleeve 15, transmission rocker 16, frying plate support crankshaft 17, installation sleeve 18.

[0040] The fried tea assembly includes arc-shaped frying plate 19, wok 20, wok retaining ring 21, wok heating plate 22, photoelectric switch reflector 23, photoelectric switch 24, photoelectric switch reflector fixing seat 25, photoelectric switch support 49 .

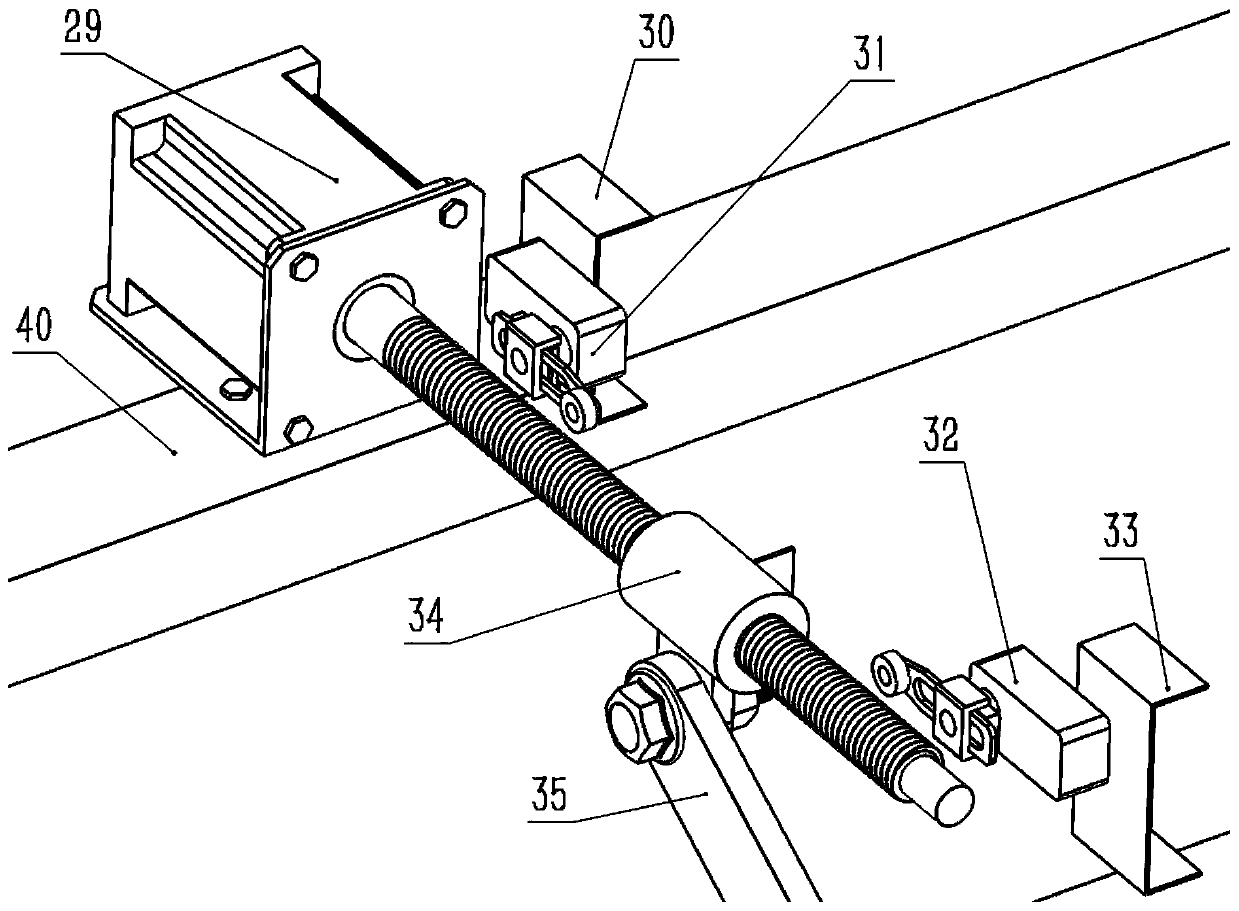

[0041] The swing adjustment assembly includes a stepper motor 26 , an adjustment assembly bracket 27 , a double cross sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com