Quasi-parallel linetype clamp-sample alignment point obtaining method

A technology of parallel lines and directrixes, applied in the field of obtaining quasi-parallel line-type card-like directrix points, can solve the problem of single method for obtaining directrix points, and achieve standard and accurate calculations, convenient and unified storage and The effect of later transportation and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

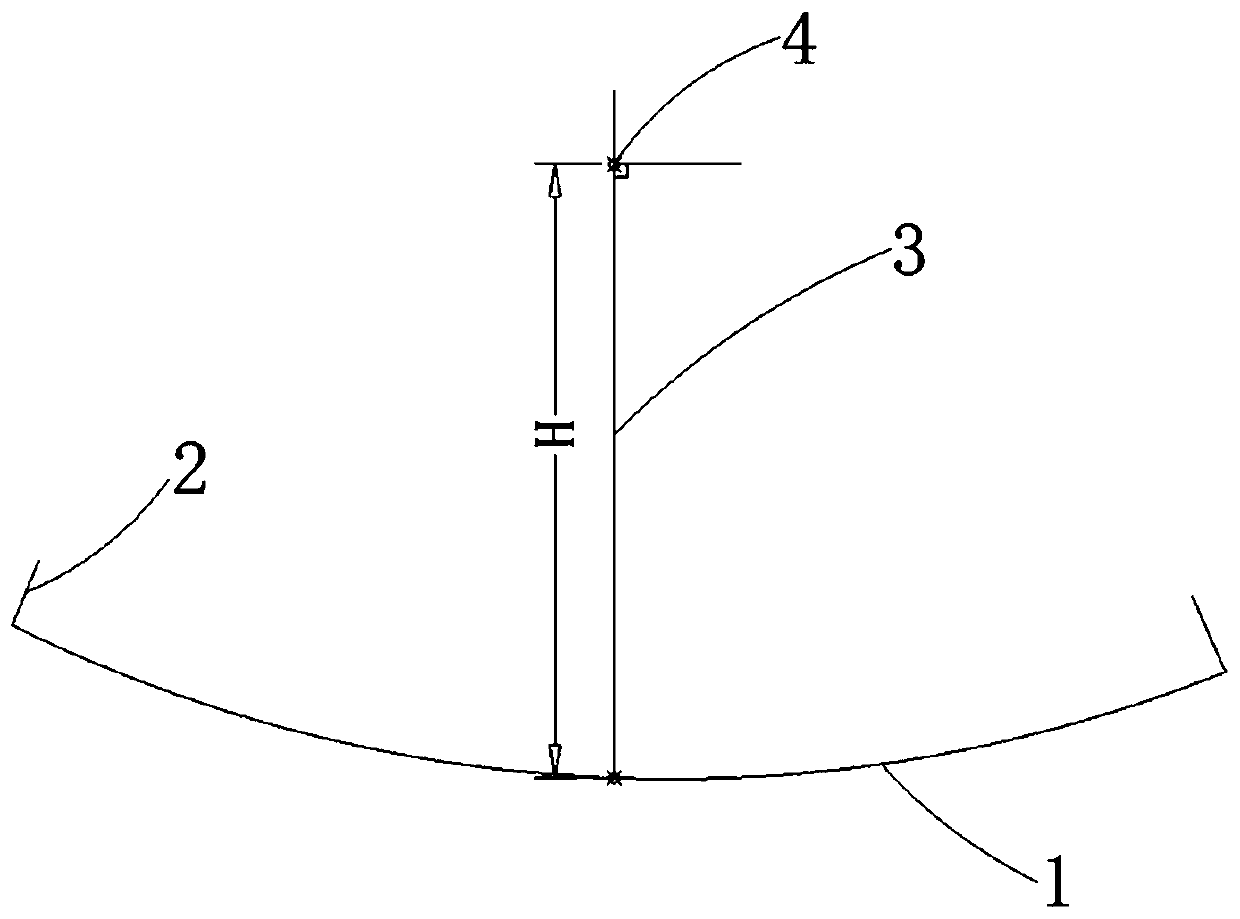

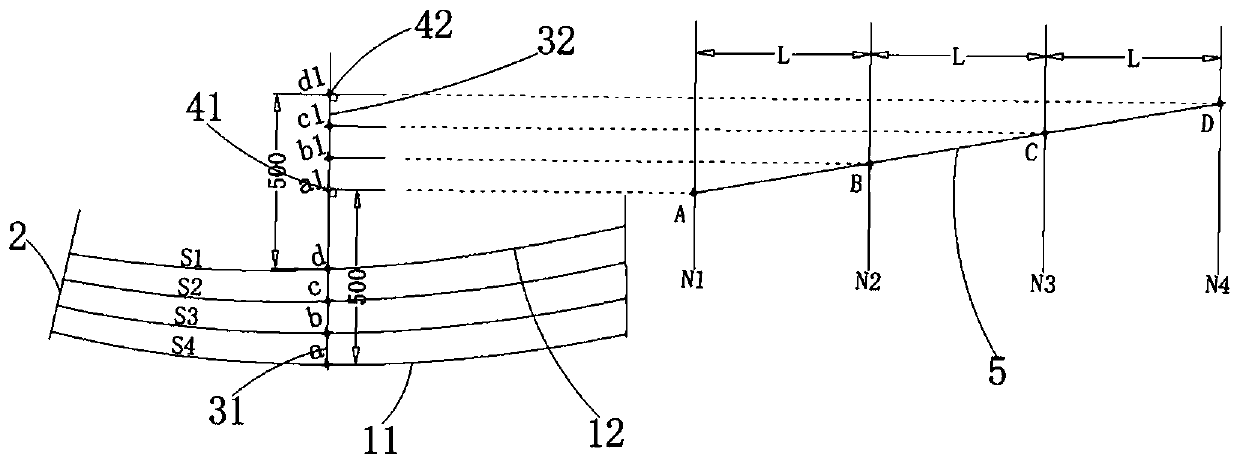

[0031] Such as image 3 As shown, in this embodiment, the case that the lengths of each card-like line type are consistent is described, and the method for obtaining the card-like alignment point of the quasi-parallel line type includes the following steps:

[0032] S1: The middle position of the first card-like line pattern 11 is used as the first perpendicular line, and the middle position of the tail card-like line pattern 12 is used as the tail perpendicular line, and the first perpendicular line and the tail perpendicular line are parallel;

[0033] Specifically, there are a total of four clamping line types in this embodiment. It should be noted that the clamping line type is the line type part of the curved panel intercepted at the position of the rib line type. In this embodiment, there are a total of four A part of the line type of the curved panel is intercepted at the line type. The ends of the four clamping line types are all drawn with a plate seam 2, which is eq...

Embodiment 2

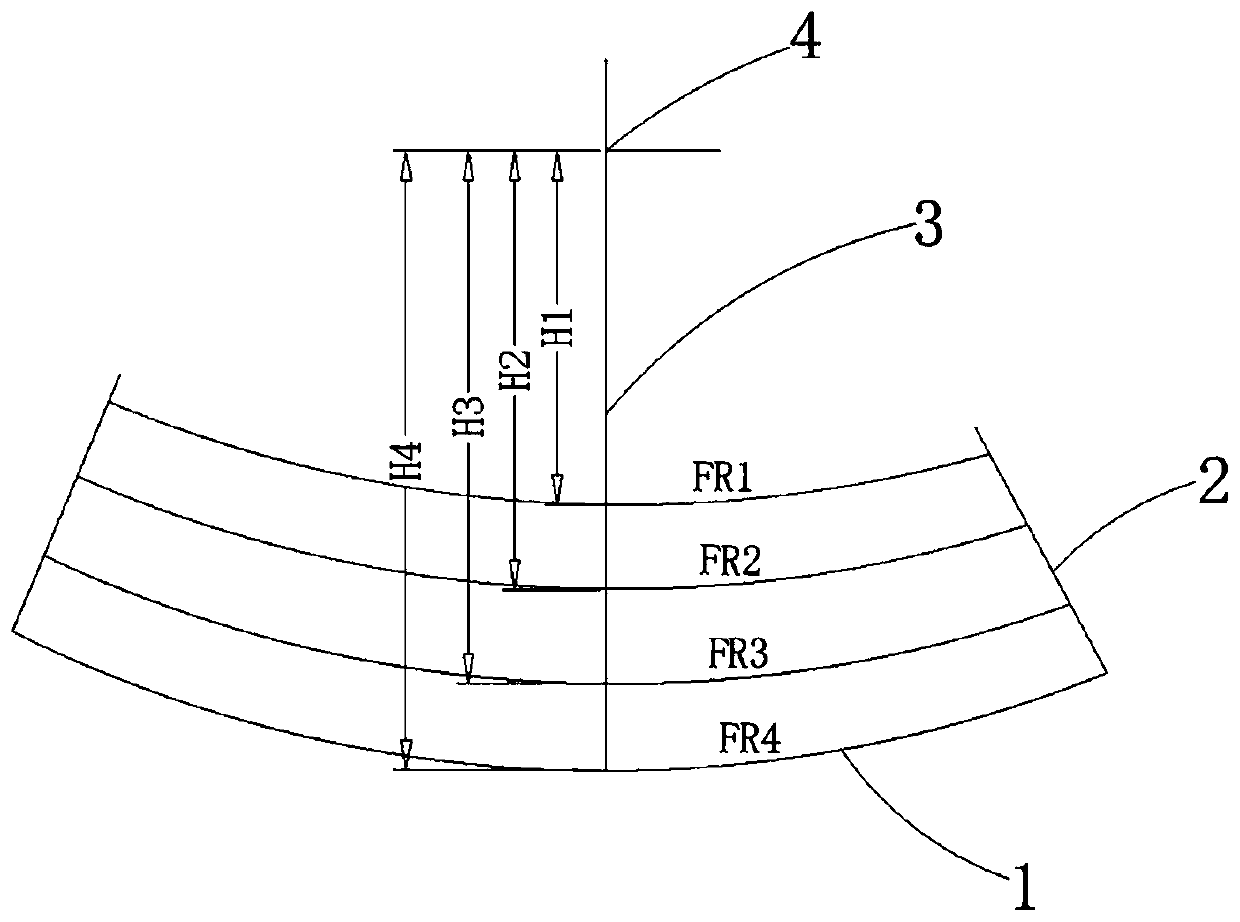

[0049] Such as Figure 4 As shown, in this embodiment, the situation that the lengths of each card-like line type are greatly different is described. The method for calculating the card-like alignment point of the quasi-parallel line type in this embodiment includes the following steps:

[0050] S1: The middle position of the first card-like line pattern 11 is used as the first perpendicular line, and the middle position of the tail card-like line pattern 12 is used as the tail perpendicular line, and the first perpendicular line and the tail perpendicular line are parallel;

[0051] Specifically, this embodiment also includes four parallel card-like line types, the four card-like line types are respectively curve F1, curve F2, curve F3 and curve F4, and the lengths of curve F1, curve F2, curve F3 and curve F4 The side lengths are gradually increased in order, wherein the curve F1 is the shortest and the curve F4 is the longest. Make the first perpendicular and the tail perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com