Multi-split air conditioner leakage position automatic positioning method, device and equipment

A leakage location and automatic positioning technology, which is applied in the direction of mechanical equipment, lighting and heating equipment, heating methods, etc., can solve the problems of manpower and time consumption, and achieve the effect of saving time and cost and achieving high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

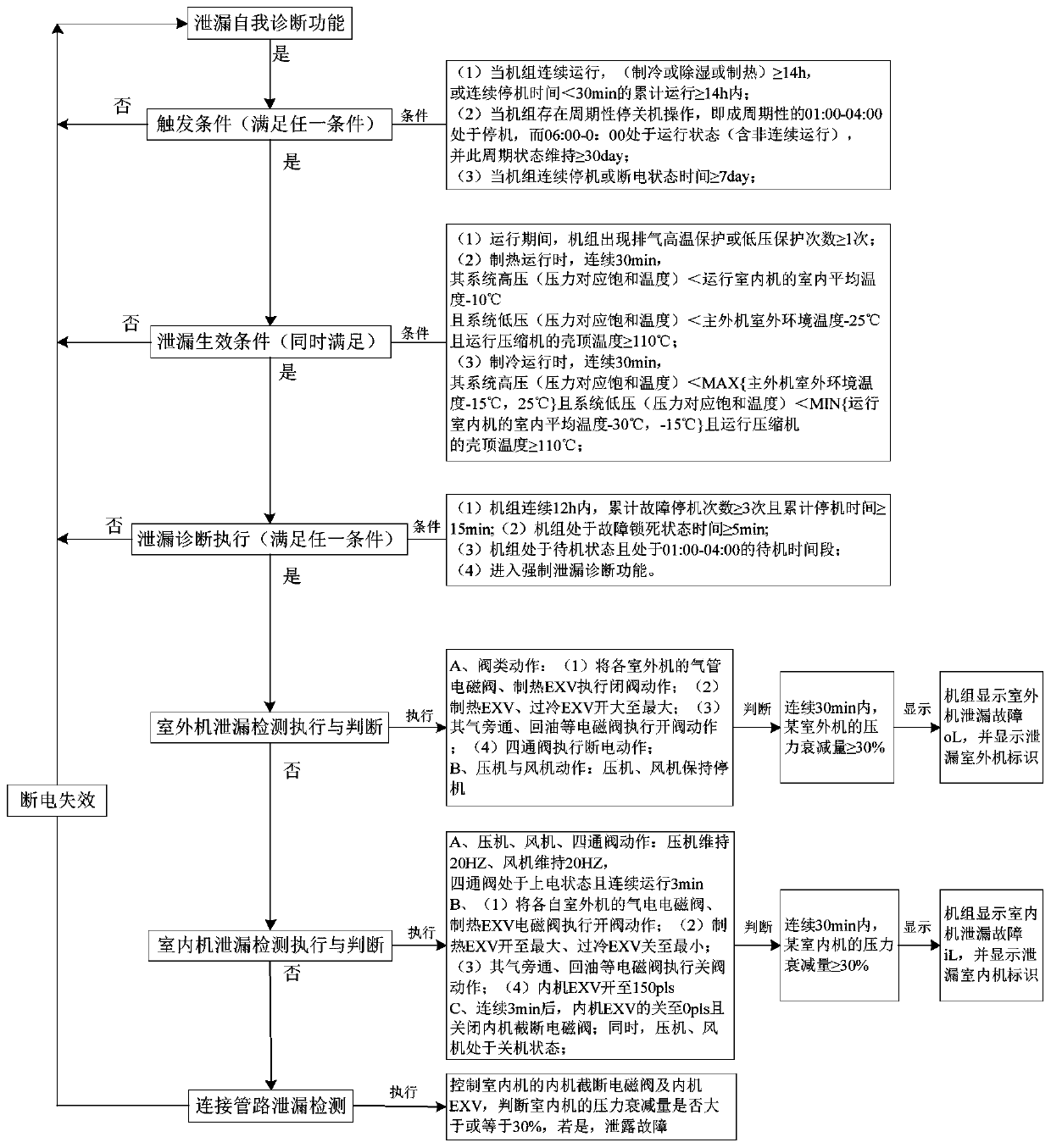

[0095] figure 1 It is a flow chart of the multi-line leak location automatic location method provided by Embodiment 1 of the present invention, as shown in figure 1 As shown, the method includes the following steps:

[0096] S101. Determine that the current running state of the multi-line unit satisfies the leak location location condition.

[0097] Among them, the multi-connection includes multiple outdoor units and multiple indoor units, and one outdoor unit can correspond to one or more indoor units. The multi-line leak location location condition is used to start the leak location (also called leak point) self-diagnosis process. If the current operating status of the multi-line meets the leak location location conditions, it can enter the leak location self-diagnosis process and perform related operations.

[0098] S102. Control each outdoor unit and each indoor unit according to a preset operation, and determine the leakage position of the multi-connection unit accordi...

Embodiment 2

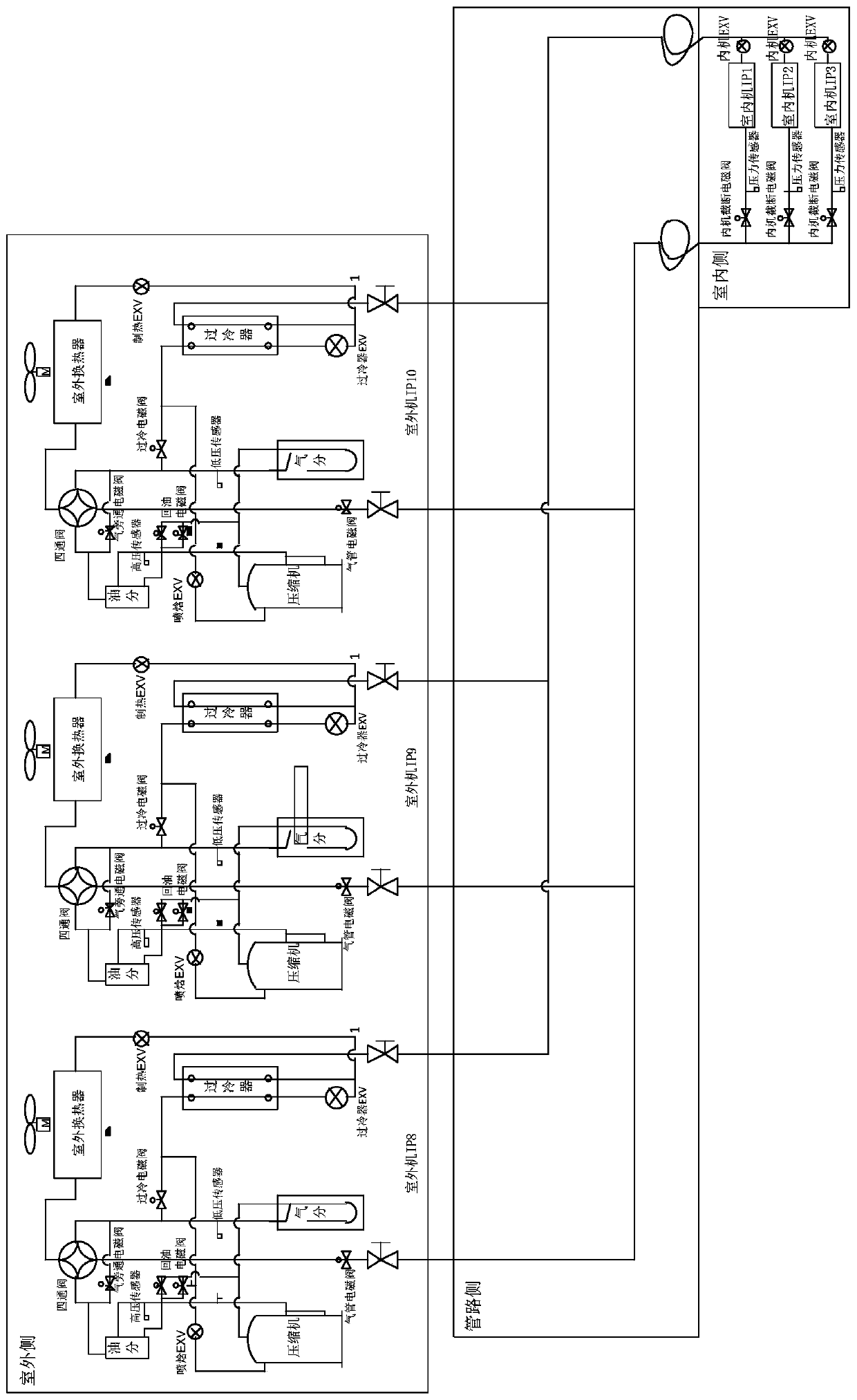

[0155] figure 2 It is a schematic structural diagram of the multi-connection provided by Embodiment 2 of the present invention, such as figure 2As shown, the multi-connection includes multiple outdoor units and multiple indoor units, and each outdoor unit and each indoor unit is provided with its own unique identification information. The corresponding outdoor units are connected to the indoor units through connecting pipelines. In order to realize block detection, valves are set between the outdoor unit and the indoor unit to separate them, such as the valve close to the connecting pipeline of the outdoor unit and the internal unit cut-off solenoid valve of the indoor unit. In this embodiment, whether there is leakage is judged by the amount of pressure attenuation, therefore, pressure sensors are provided in the outdoor unit and the indoor unit. In the outdoor unit, the pipeline between the compressor and the oil-gas separator is a high-pressure pipeline, and the pipelin...

Embodiment 3

[0209] This embodiment provides a multi-line leakage position automatic positioning device, which can be used to implement the multi-line leakage position automatic positioning method described in the above embodiment. Figure 4 It is a structural block diagram of the multi-line leak location automatic positioning device provided by the third embodiment of the present invention, as shown in Figure 4 As shown, the device includes:

[0210] A condition determining module 401, configured to determine that the current operating state of the multi-line meets the leak location location condition;

[0211] Leakage position determination module 402, configured to control each outdoor unit and each indoor unit according to preset operations, and determine the leakage position of the multi-connector according to the diagnostic parameters.

[0212] Optionally, the condition determination module 401 includes:

[0213] a first condition judging unit, configured to judge whether the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com