Parallel thrust vector exhaust system based on throat offset type pneumatic vector spray pipe

A technology of vectoring nozzle and thrust vectoring, which is applied in the directions of jet propulsion, machine/engine, etc., can solve the problems of unfavorable high-speed flight of aircraft, normal engine, high-efficiency work, and large convergence angle of the outer surface of the nozzle. Improve infrared stealth performance, have universality, and improve the effect of rear body flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

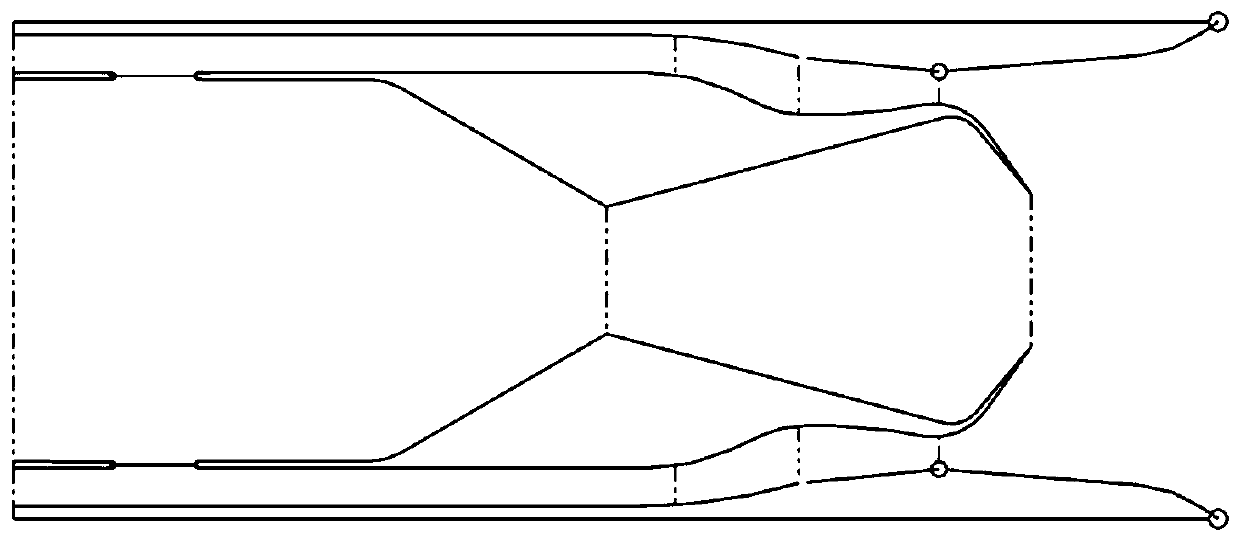

[0056] A typical configuration of a parallel thrust vectoring exhaust system based on throat offset aerodynamic vectoring nozzles is calculated.

[0057] Figure 6 Shown is the numerically calculated Mach number cloud diagram when NPR=4. It can be seen that through the preliminary profile optimization design, when the vector is deflected downward, the airflow of the Laval channel on the upper side channel is not ejected backwards, but is disturbed by the center throat offset aerodynamic vector nozzle Next, flow along the outer wall of the throat offset aerodynamic vector nozzle to achieve deflection. At the same time, the airflow of the lower side channel flows along the tail surface of the nozzle Laval channel and is deflected downward together, thus achieving better vector performance.

[0058] Figure 7 Shown is its data calculation curve. Among them, BDTN basic is the curve of the vector angle of the throat offset aerodynamic vector nozzle with the same profile as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com