High-efficiency fireproof flame-retardant cable

A fire retardant and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as the inability to meet fire protection requirements, and achieve the effect of improving fire retardant and flame retardant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

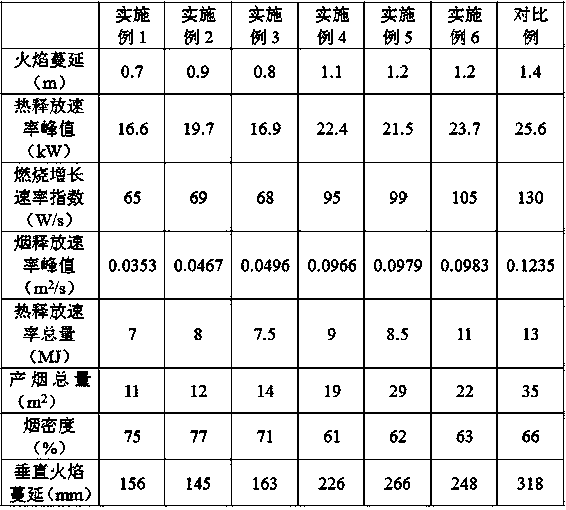

Embodiment 1

[0021] A high-efficiency fireproof and flame-retardant cable, including a core wire, a cable-forming layer, and a sheath layer, the core wire is connected to the cable-forming layer, and the cable-forming layer is connected to the sheath layer; the core wire includes a conductor and an insulating layer , the insulating layer is connected with the cable-forming layer; the cable-forming layer includes a non-woven fabric layer and a polypropylene layer, and the core wire is twisted and covered with a non-woven fabric, and a non-woven fabric is formed on the twisted core wire cloth layer, and then cover polypropylene material on the non-woven fabric layer to form a polypropylene layer; the preparation method of the polypropylene material is: take 55 parts by mass of polypropylene, 10 parts by mass of EPDM rubber, high polyphosphoric acid 6 parts by mass of ammonium, 1.5 parts by mass of dipentaerythritol, 6 parts by mass of melamine, 10 parts by mass of nano-zinc oxide, 0.15 parts ...

Embodiment 2

[0024] A high-efficiency fireproof and flame-retardant cable, including a core wire, a cable-forming layer, and a sheath layer, the core wire is connected to the cable-forming layer, and the cable-forming layer is connected to the sheath layer; the core wire includes a conductor and an insulating layer , the insulating layer is connected with the cable-forming layer; the cable-forming layer includes a non-woven fabric layer and a polypropylene layer, and the core wire is twisted and covered with a non-woven fabric, and a non-woven fabric is formed on the twisted core wire cloth layer, and then cover polypropylene material on the non-woven fabric layer to form a polypropylene layer; the preparation method of the polypropylene material is: take 50 mass parts of polypropylene, 8 mass parts of EPDM rubber, high polyphosphoric acid 4 parts by mass of ammonium, 1 part by mass of dipentaerythritol, 2 parts by mass of melamine, 5 parts by mass of nano-zinc oxide, 0.1 part by mass of vi...

Embodiment 3

[0026]A high-efficiency fireproof and flame-retardant cable, including a core wire, a cable-forming layer, and a sheath layer, the core wire is connected to the cable-forming layer, and the cable-forming layer is connected to the sheath layer; the core wire includes a conductor and an insulating layer , the insulating layer is connected with the cable-forming layer; the cable-forming layer includes a non-woven fabric layer and a polypropylene layer, and the core wire is twisted and covered with a non-woven fabric, and a non-woven fabric is formed on the twisted core wire cloth layer, and then cover the polypropylene material on the non-woven fabric layer to form a polypropylene layer; the preparation method of the polypropylene material is: take 60 parts by mass of polypropylene, 12 parts by mass of EPDM rubber, high polyphosphoric acid 8 parts by mass of ammonium, 2 parts by mass of dipentaerythritol, 8 parts by mass of melamine, 12 parts by mass of nano-zinc oxide, 0.2 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com