A steel bar bending device for building construction

A technology for steel bar bending and building construction, applied in the field of construction equipment, can solve the problems of inability to precisely control the bending degree and low quality of steel bar bending, and achieve the effects of improving bending accuracy, improving efficiency, and flexible steel bar bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

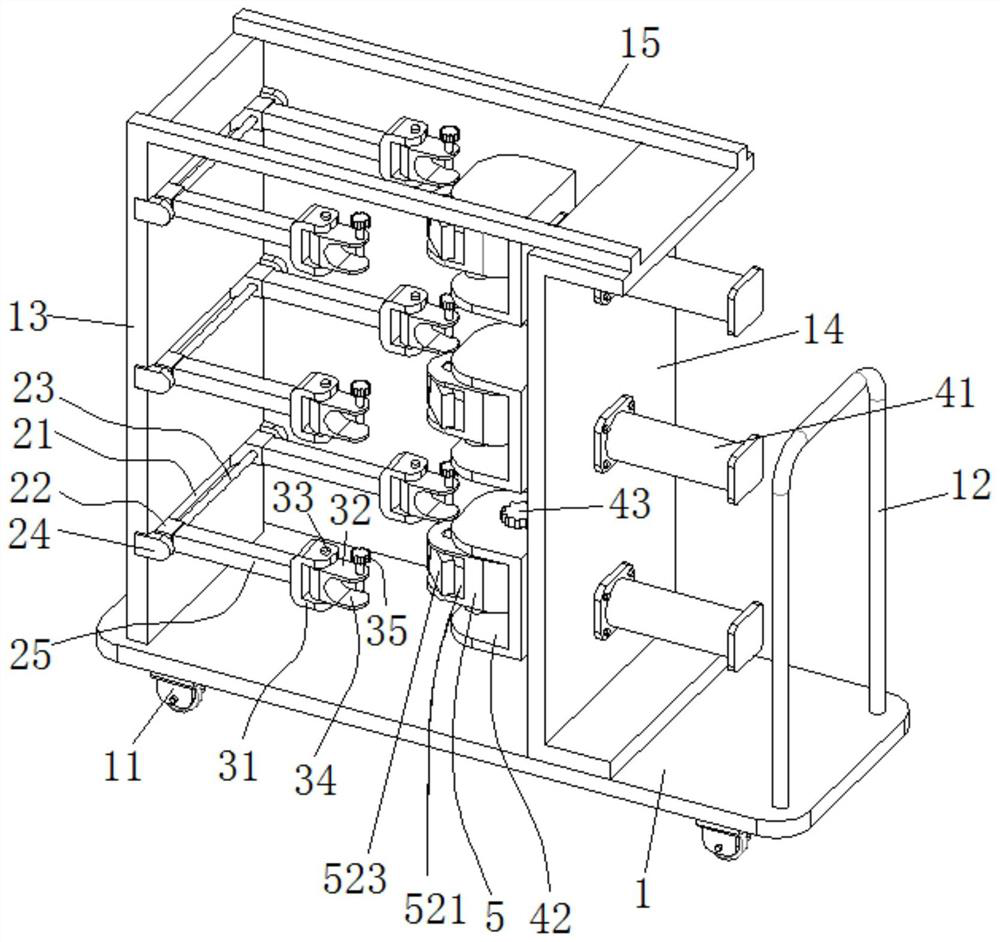

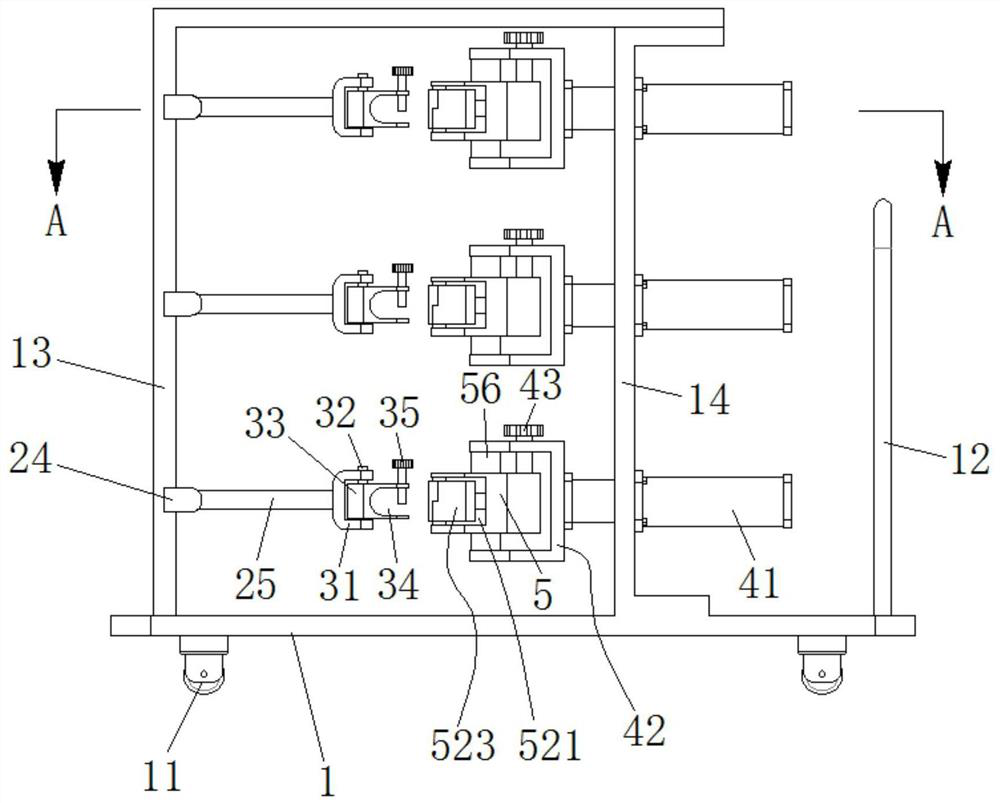

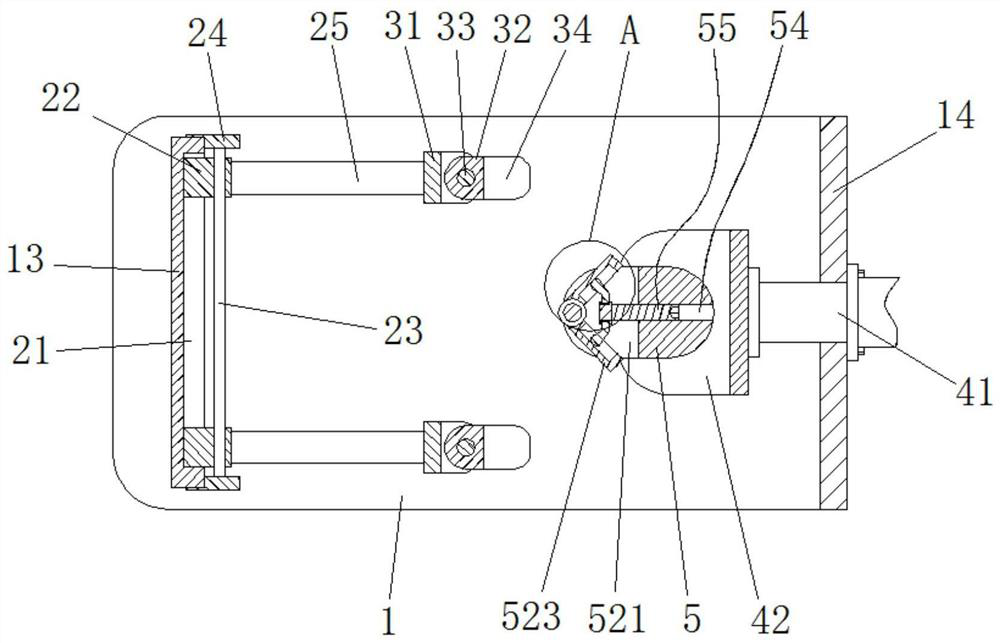

[0034] When bending multiple steel bars with a semi-circular arc structure, first fix multiple steel bars on the steel bar fixing part, then rotate the arc-shaped bending part 51 of the bending block 5, and face the bending point of the steel bar direction, then fix the bending block 5 by the limit mechanism, after fixing, start the telescopic oil cylinder 41 at the same time, push the bending block 5 to bend the steel bar, and then obtain the bent steel bar with a semicircular arc structure.

Embodiment 2

[0036] When performing multiple bent steel bars with an angular structure, first fix the multiple steel bars on the steel bar fixing part, then rotate the angular bending part 52 of the bending block 5, and face the direction of the bending point of the steel bar, Then the bending block 5 is fixed by the limit mechanism. After fixing, the opening angle of the two bending plates 523 is adjusted through the adjusting bolt 55. After adjusting to the required opening angle position, the telescopic oil cylinder 41 is started at the same time to push the bending block 5 to bend steel bar, a curved steel bar with an angular structure is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com