Electric stewing pot

An electric stewing and outer pot technology, which is applied to cooking utensils, household appliances, applications, etc., can solve the problems of poor sealing performance of the pot cover to the cooking cavity, reducing the heating efficiency of the electric stew pot, and poor sound insulation performance of the pot cover. The effect of massive loss of steam, ease of appearance proportions, reduced design and adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

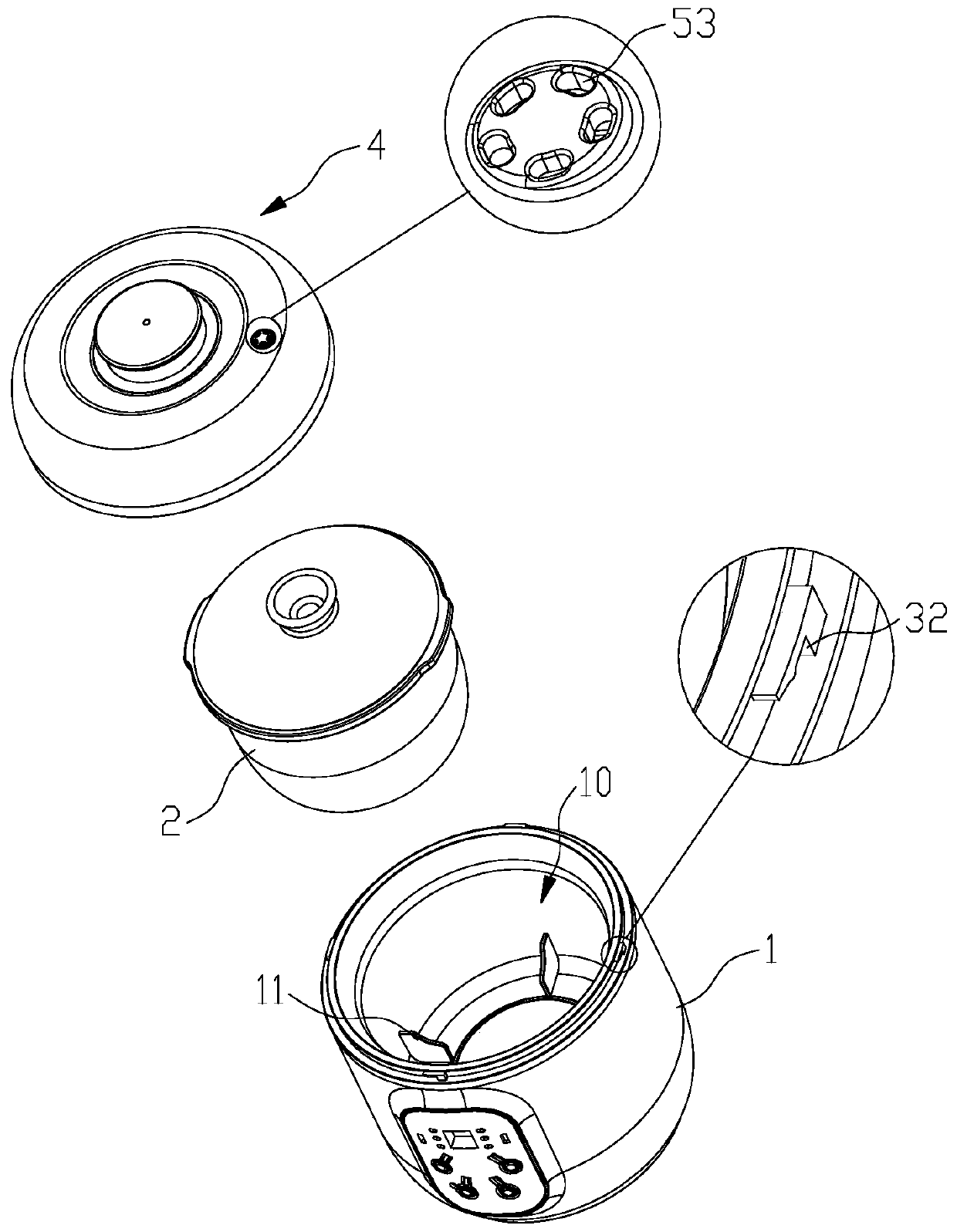

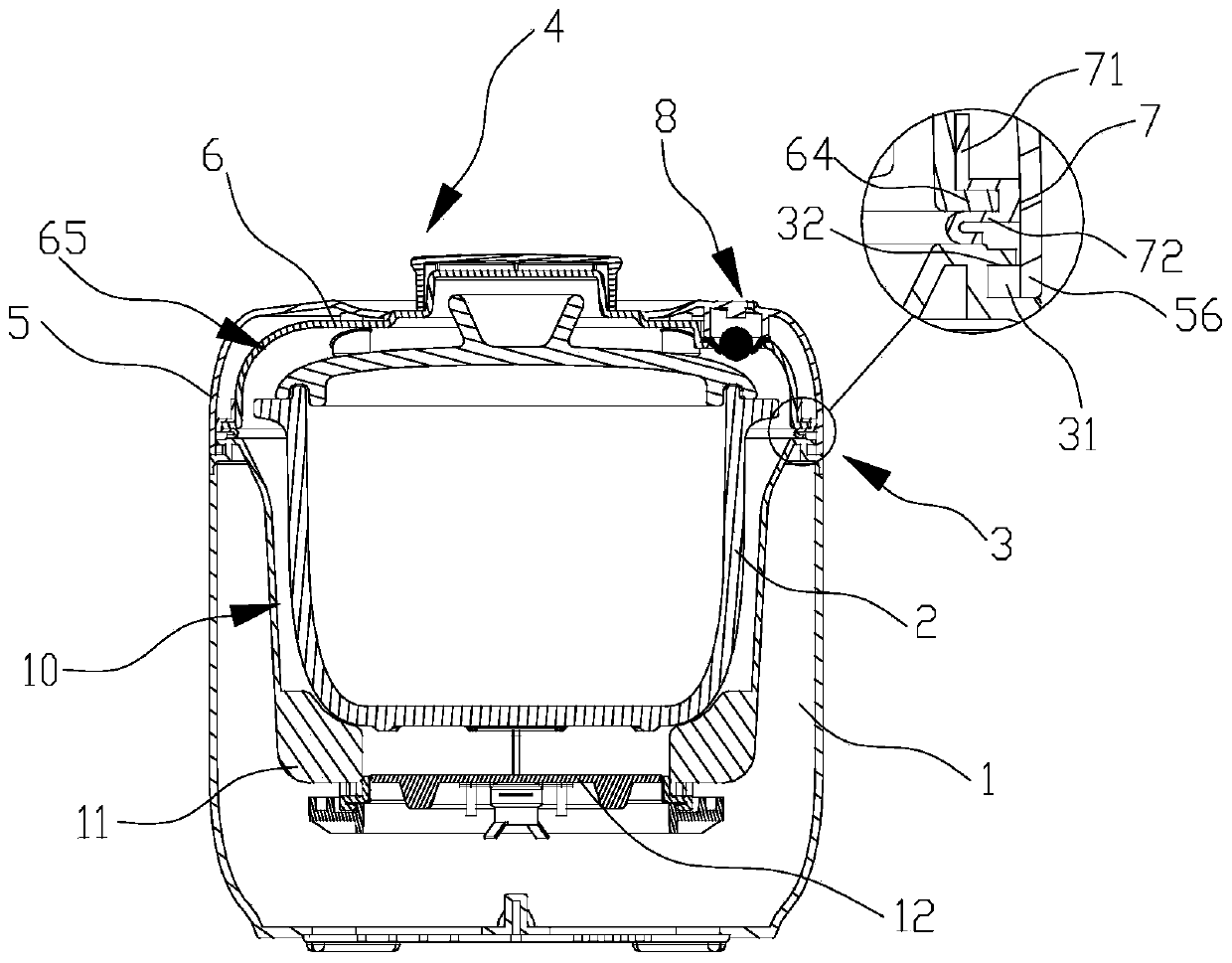

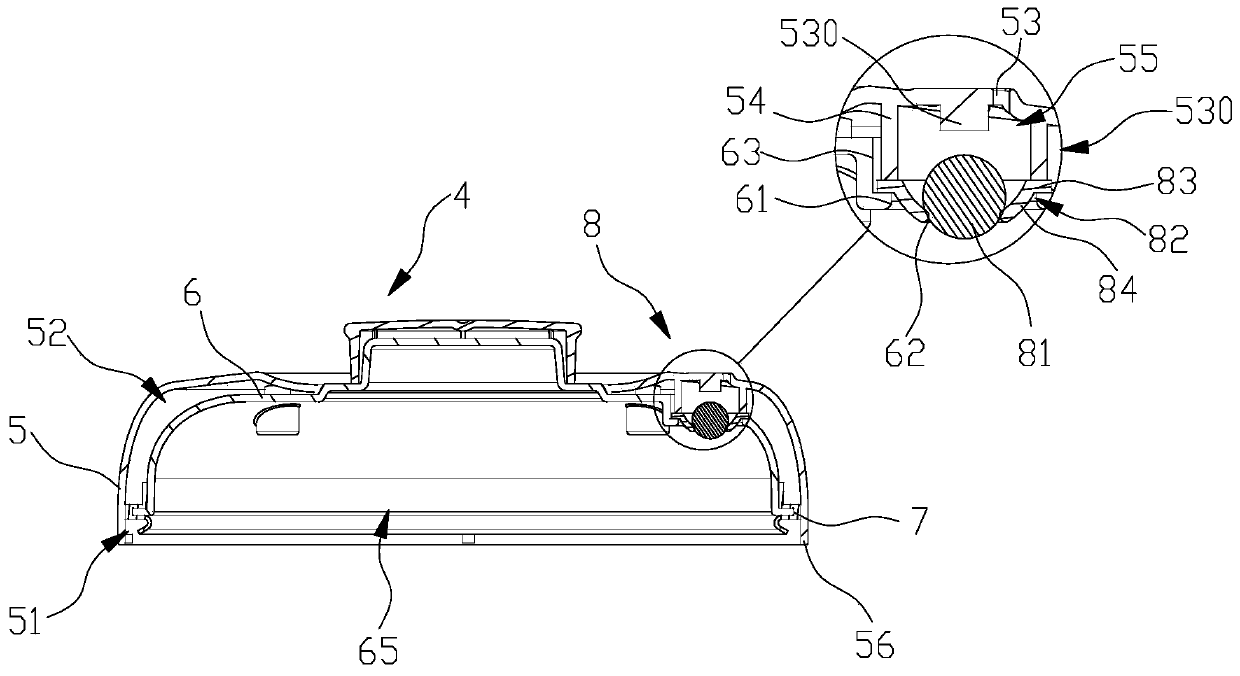

[0030] see Figure 1 to Figure 5, an electric stew pot according to this embodiment, comprising a pot cover 4, an outer pot 1 and an inner pot 2; Component 12; the inner tank 2 is set in the heating inner cavity 10; the pot cover 4 is sealed on the upper opening of the outer pot 1, and the pot cover 4 is provided with an inward valve structure 8, so The inward valve structure 8 includes an exhaust hole 53, a gas exchange channel 55, an air inlet 62 and a pressurized ball 81; the exhaust hole 53 is arranged on the pot cover 4 for communicating with the outside world, and the gas exchange The channel 55 is arranged on the pot cover 4 and extends along the lower side of the pot cover 4 , the gas exchange channel 55 communicates with the exhaust hole 53 , and the air inlet 62 is arranged at the lower end of the gas exchange channel 55 And communicated with the heating inner cavity 10 , the pressurized ball 81 is movably arranged in the gas exchange channel 55 for sealing or openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com