Square dual-frequency microstrip patch antenna

A microstrip patch antenna, square technology, applied in the direction of antenna grounding switch structure connection, radiation element structure, etc., can solve the problems of not improving the axial ratio performance, affecting the circular polarization of the antenna, and poor antenna axial ratio performance, etc., to achieve Ease of processing, design and assembly, improved circular polarization performance, and stable phase center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

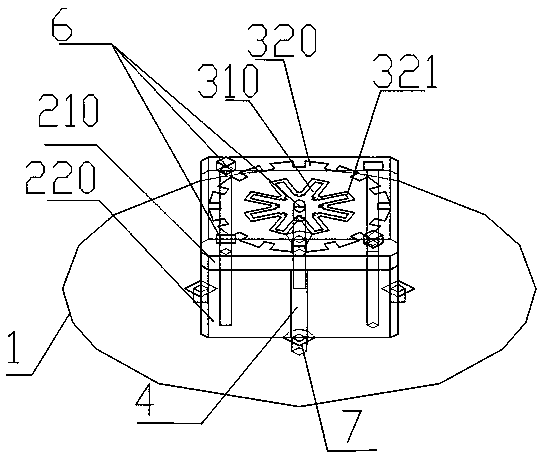

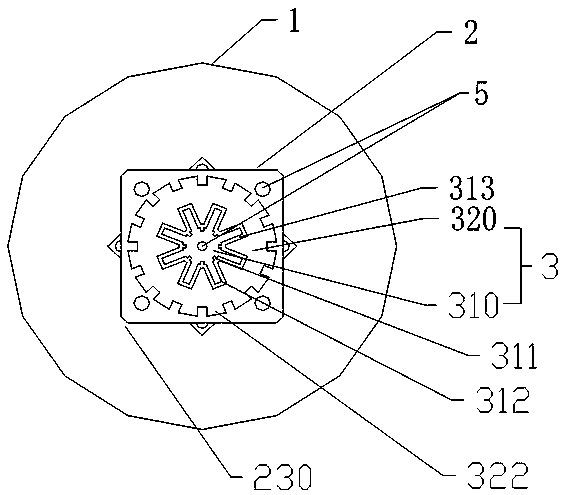

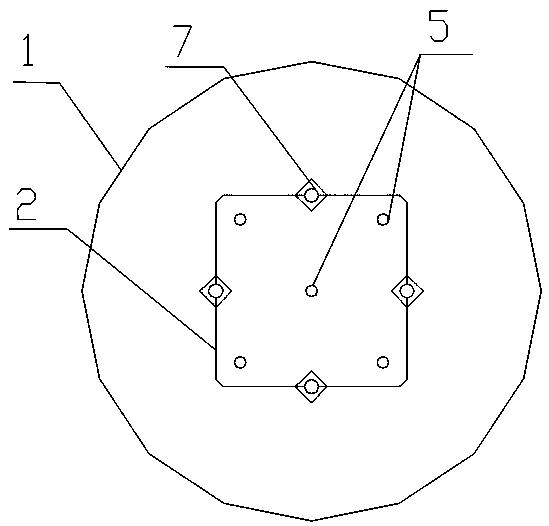

[0038] Such as Figure 1-3 As shown, a square dual-frequency microstrip patch antenna includes: a conductive ground plane 1, a dielectric substrate 2 disposed on the conductive ground plane, a radiation sheet 3 disposed on the top of the dielectric substrate, and a dielectric substrate surrounded by Several feeding probes 4 on the side wall;

[0039] The radiating sheet 3 includes a concentric first radiating sheet 310 and a second radiating sheet 320, the first radiating sheet resonates to generate a high frequency, and the second radiating sheet resonates to generate a low frequency, forming a high and low frequency band;

[0040] The first radiating sheet 310 is a gear-shaped thin sheet, and a groove 311 is processed at the center of each alveolar bottom of the gear-shaped first radiating sheet;

[0041] The second radiating sheet 320 is a circular thin sheet with jagged outer edges, the second radiating sheet is larger than the first radiating sheet, and the middle part o...

Embodiment 2

[0055] The feeding probe feeds the first radiating sheet and the second radiating sheet in a coupled feeding manner.

[0056] Such as Figure 4 , using 4 orthogonal feeding probes, every two adjacent ones undergo signal phase shifting, and a good circularly polarized signal output is obtained after combining, where Hybrid is a coupler with a phase shift of 90 degrees.

[0057] Four feeding probes have good circular polarization performance, and the phase center is stable due to the symmetry of the antenna.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com