Method for directly measuring bonding performance of PEC type steel reinforced concrete bonding surface

A technology of bonding performance and concrete, which is applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of accuracy influence, error, etc., to reduce the test error, reduce the test error, and simplify the operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] This embodiment mainly includes the following steps:

[0045] 1. Arrangement of steel strain gauges

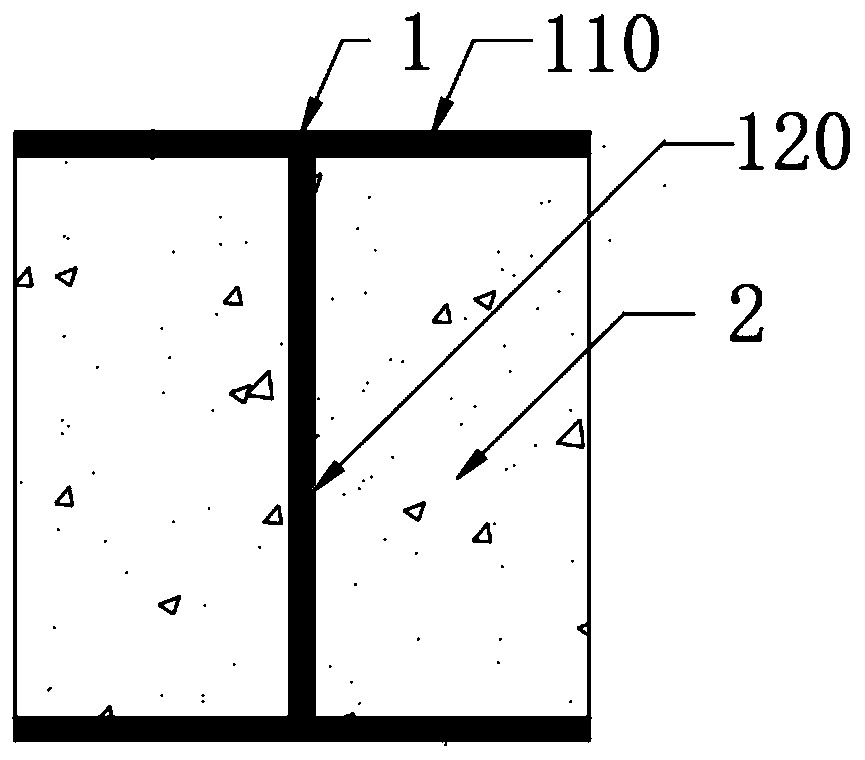

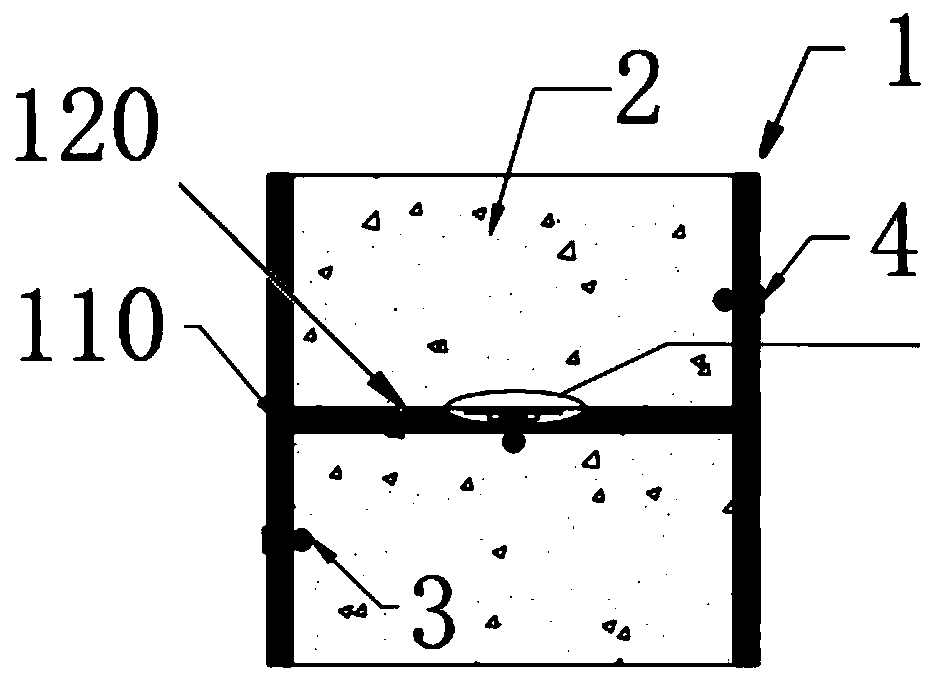

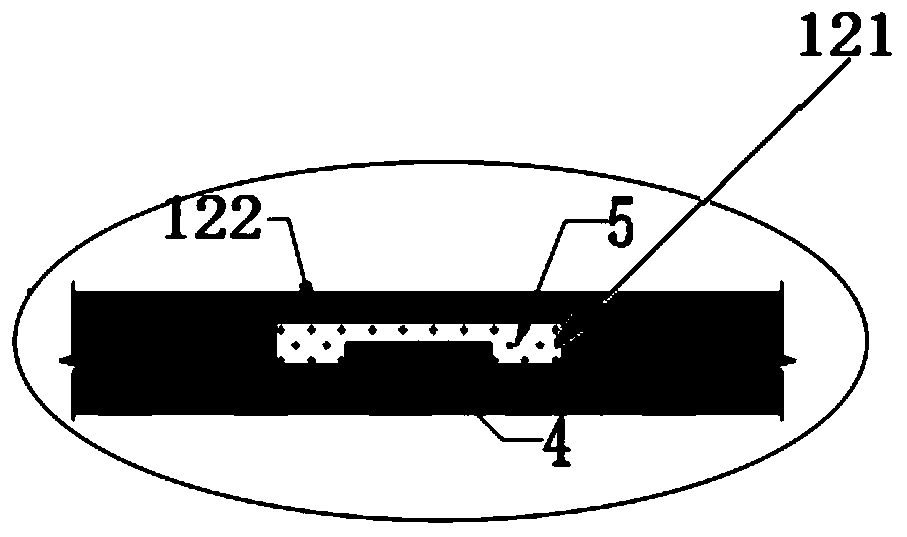

[0046] see Figure 2~3 1. Paste steel strain gauges 4 at corresponding steel strain measurement points outside the flange 110 of the H-shaped steel 1 . Since the two sides of the web 120 are in contact with the concrete, the steel strain gauges cannot be pasted directly on the surface of the web 120, so grooves are made on the surface of the web 120, the steel strain gauges 4 are pasted in the groove 121, and filled with epoxy resin 5 . Considering that the contact between the epoxy resin and the concrete surface will affect the bonding performance between the web and the concrete as a whole, a new type of groove 121 is designed, that is, an inverted "convex" groove 121.

[0047] see image 3 , the groove 121 is divided into two layers. The slotting method is as follows: First, a slot with a width of 4 mm and a depth of 1.0 mm is opened along the longitudinal axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com