Method for preparing alcohol-free beer with strong faint scent

A non-alcoholic beer, fragrance technology, applied in the field of beer production, can solve the problems of low alcohol concentration, bland taste, lack of strong fragrance and bitterness of beer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

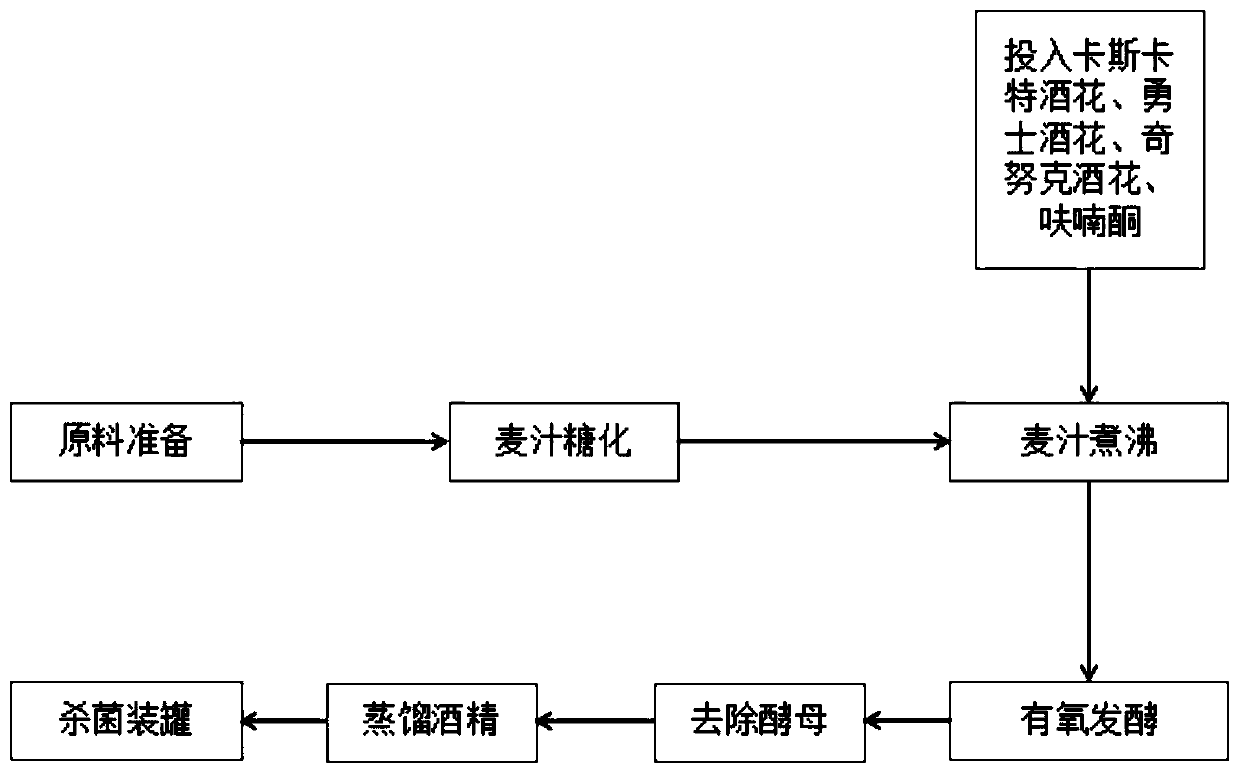

Method used

Image

Examples

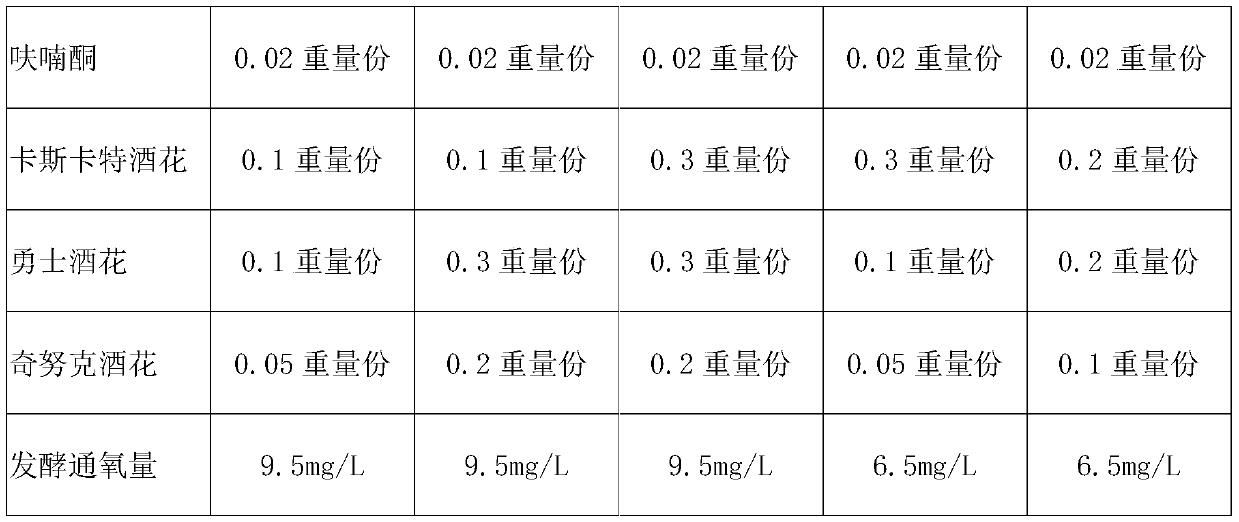

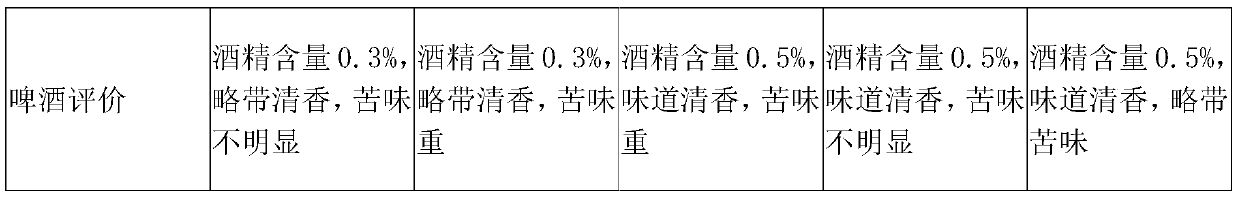

Embodiment 1

[0028] A method for preparing non-alcoholic beer with strong fragrance, characterized in that said method comprises the following steps:

[0029] S1 raw material preparation:

[0030] Select 100 parts by weight of Australian pilsner malt, 400 parts by weight of mountain spring water, 0.1 part by weight of Cascade hops, 0.1 parts by weight of Warrior hops, 0.05 parts by weight of Chinook hops, and 0.02 parts by weight of furanone;

[0031] S2 wort mashing:

[0032] Crush 100 parts by weight of Australian pilsner malt to 1 / 4 size, pour it into the mash tank, add 400 parts by weight of mountain spring water, heat to 55°C, keep it for 10 minutes, then raise the temperature to 68°C, keep it warm for 50 minutes, control The concentration of the mixed wort is 16°P, and the wort is filtered through a filter washing tank to obtain saccharified wort;

[0033] S3 wort boiling:

[0034] Introduce the saccharified wort obtained in S2 into a boiling pot for boiling, first add 0.02 parts ...

Embodiment 2

[0044] S1 raw material preparation:

[0045] Select 100 parts by weight of Australian pilsner malt, 400 parts by weight of mountain spring water, 0.3 parts by weight of Cascade hops, 0.3 parts by weight of Warrior hops, 0.2 parts by weight of Chinook hops, and 0.02 parts by weight of furanone;

[0046] S2 wort mashing:

[0047] Crush 100 parts by weight of Australian pilsner malt to 1 / 4 size, pour it into the mash tank, add 400 parts by weight of mountain spring water, heat to 55°C, keep it for 10 minutes, then raise the temperature to 68°C, keep it warm for 50 minutes, control The concentration of the mixed wort is 16°P, and the wort is filtered through a filter washing tank to obtain saccharified wort;

[0048] S3 wort boiling:

[0049] Introduce the saccharified wort obtained in S2 into a boiling pot for boiling, first add 0.02 parts by weight of furanone, add 0.3 parts by weight of Cascade hops 5 minutes after boiling, add 0.3 parts by weight of Warrior hops after boilin...

Embodiment 3

[0059] S1 raw material preparation:

[0060] Select 100 parts by weight of Australian pilsner malt, 400 parts by weight of mountain spring water, 0.2 parts by weight of Cascade hops, 0.2 parts by weight of Warrior hops, 0.1 parts by weight of Chinook hops, and 0.02 parts by weight of furanone;

[0061] S2 wort mashing:

[0062] Crush 100 parts by weight of Australian pilsner malt to 1 / 4 size, pour it into the mash tank, add 400 parts by weight of mountain spring water, heat to 55°C, keep it for 10 minutes, then raise the temperature to 68°C, keep it warm for 50 minutes, control The concentration of the mixed wort is 16°P, and the wort is filtered through a filter washing tank to obtain saccharified wort;

[0063] S3 wort boiling:

[0064] Introduce the saccharified wort obtained in S2 into a boiling pot for boiling, first add 0.02 parts by weight of furanone, add 0.2 parts by weight of Cascade hops 5 minutes after boiling, add 0.2 parts by weight of Warrior hops after boilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com