Offset connection fixing structure of center lines of plate springs and center lines of lower wing surfaces of longitudinal beams

A technology for fixing structures and longitudinal beams, which is applied in the direction of springs, leaf springs, vehicle springs, etc., can solve problems such as the short distance between the battery pack and the leaf spring pin mounting bolts, and does not meet the assembly clearance, so as to increase the center distance of leaf springs, Reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] See attached picture.

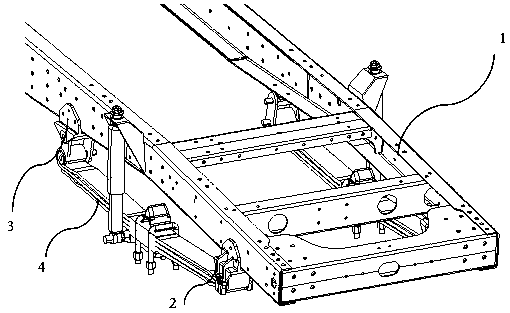

[0017] figure 1 It is a schematic diagram of the scheme. It can be seen from the figure that the front leaf spring is installed on the chassis longitudinal beam through the front and rear two lifting lugs, and the front axle is connected to the leaf spring through saddle bolts and shock pads.

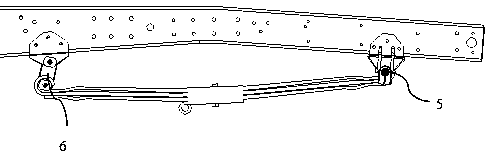

[0018] figure 2 It is the side view of the plan. It can be seen from the figure that the front lifting ear is fixed with the leaf spring through a pin, and here is an immovable dead point; the rear lifting ear is fixed with the leaf spring through a pin. is an active point that can be moved.

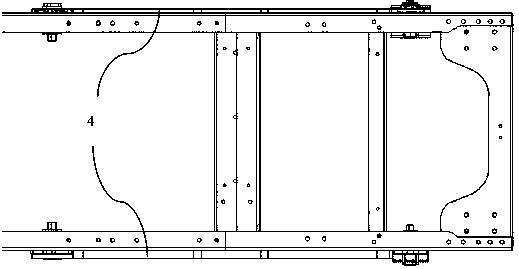

[0019] image 3 It is a top view of the plan. It can be seen from the figure that the leaf spring is covered under the lower wing surface, and the coverage size can be adjusted according to the needs of the whole vehicle.

[0020] Figure 4 It is a schematic diagram of the front and rear lifting lugs. It can be seen from the figure that the front lifting lug is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com