Fresh corbicula fluminea meat and preparation method thereof

A fresh clam technology, applied in food preservation, crustacean processing, slaughtering, etc., can solve the problems of affecting operation, deepening of clam meat color, loss of nutrients, etc., and achieves the effect of convenient operation, simple process and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

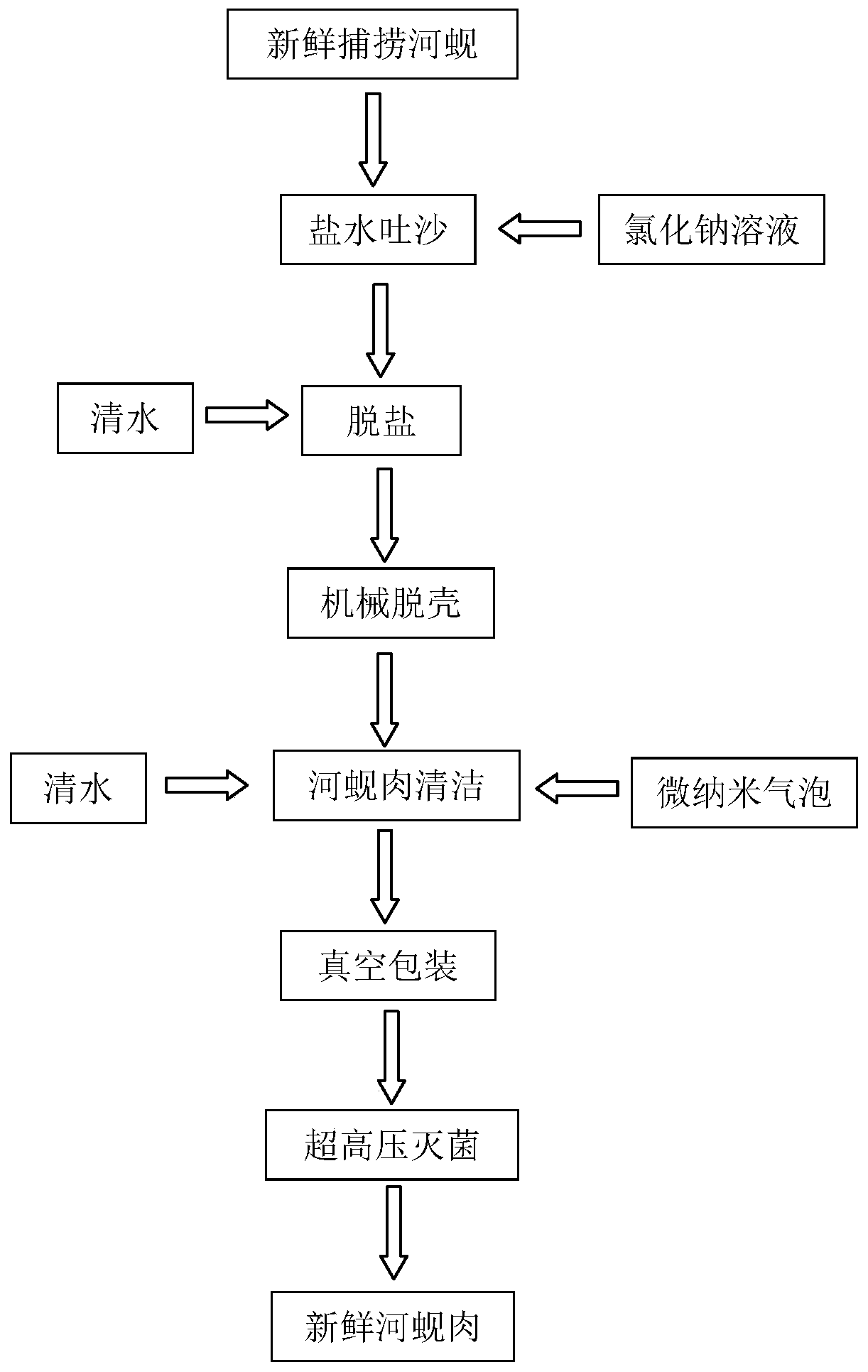

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Weigh 1 kg of freshly caught clams. The clam was submerged in a saline (NaCl) solution containing 2% (w / v), and after spewing sand for 2 hours, the clam was immersed in clean water at a temperature of 20°C for 0.5 hour to desalinate, and the desalinated river clam was Clams are mechanically dehulled. Submerge the obtained river clam meat in the aqueous solution, and pass through the micro-nano bubbles for cleaning treatment. The treatment conditions are that the diameter of the micro-nano bubbles is 0.2 μm, and the ventilation rate is 1m 3 / h, the processing time is 10 minutes. Cleaned clam meat is vacuum-packed and then sterilized by ultra-high pressure. The treatment conditions are pressure of 400 MPa, temperature of 20°C, and processing time of 5 minutes to obtain fresh clam meat. The clam meat obtained by the method has a mass retention rate of 95% per 100 grams of clam meat, a color difference ΔE value of 1.6, a protein residual rate of 96.5%, and a...

Embodiment 2

[0020] Embodiment 2: Weigh 1 kg of freshly caught clams. Immerse the clam in a 5% (w / v) saline (NaCl) solution, spit out sand for 4 hours, then immerse the clam in clean water at a temperature of 25°C for 2 hours to desalinate the desalinated river clam. Clams are mechanically dehulled. Submerge the obtained river clam meat in an aqueous solution, and pass through micro-nano bubbles for cleaning treatment. The treatment conditions are that the diameter of the micro-nano bubbles is 5 μm, and the ventilation rate is 3 m 3 / h, the processing time is 30 minutes. Cleaned clam meat is vacuum-packed and then sterilized by ultra-high pressure. The treatment conditions are pressure of 800 MPa, temperature of 40°C, and processing time of 15 minutes to obtain fresh clam meat. The clam meat obtained by this method has a quality retention rate of 92.6% per 100 grams of clam meat, a color difference ΔE value of 2.6, a protein residual rate of 93.7%, and a polysaccharide residual rate of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com