Test system applied to LED lamp test fixture

A test fixture and test system technology, applied in the use of semiconductor lamps, electrical components, electroluminescence light sources, etc., can solve the problems of low test efficiency and insufficient reliability of LED lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

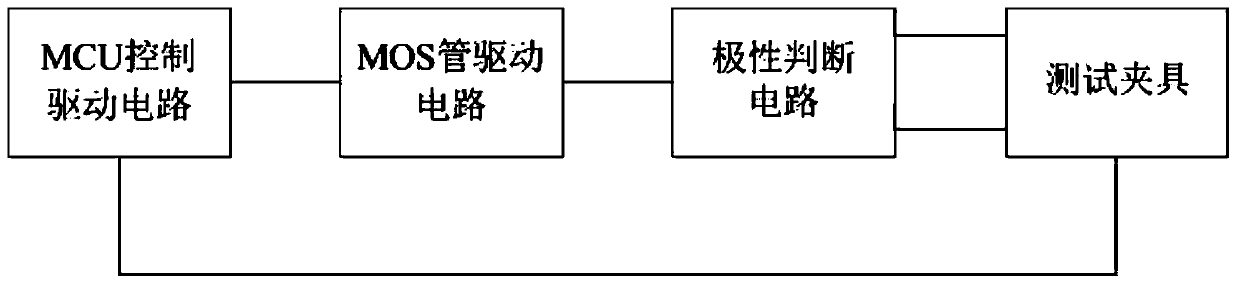

[0032] A test system applied to LED lamp test fixtures, such as figure 1 As shown, including: MCU control drive circuit, MOS tube drive circuit, polarity judgment circuit, test fixture;

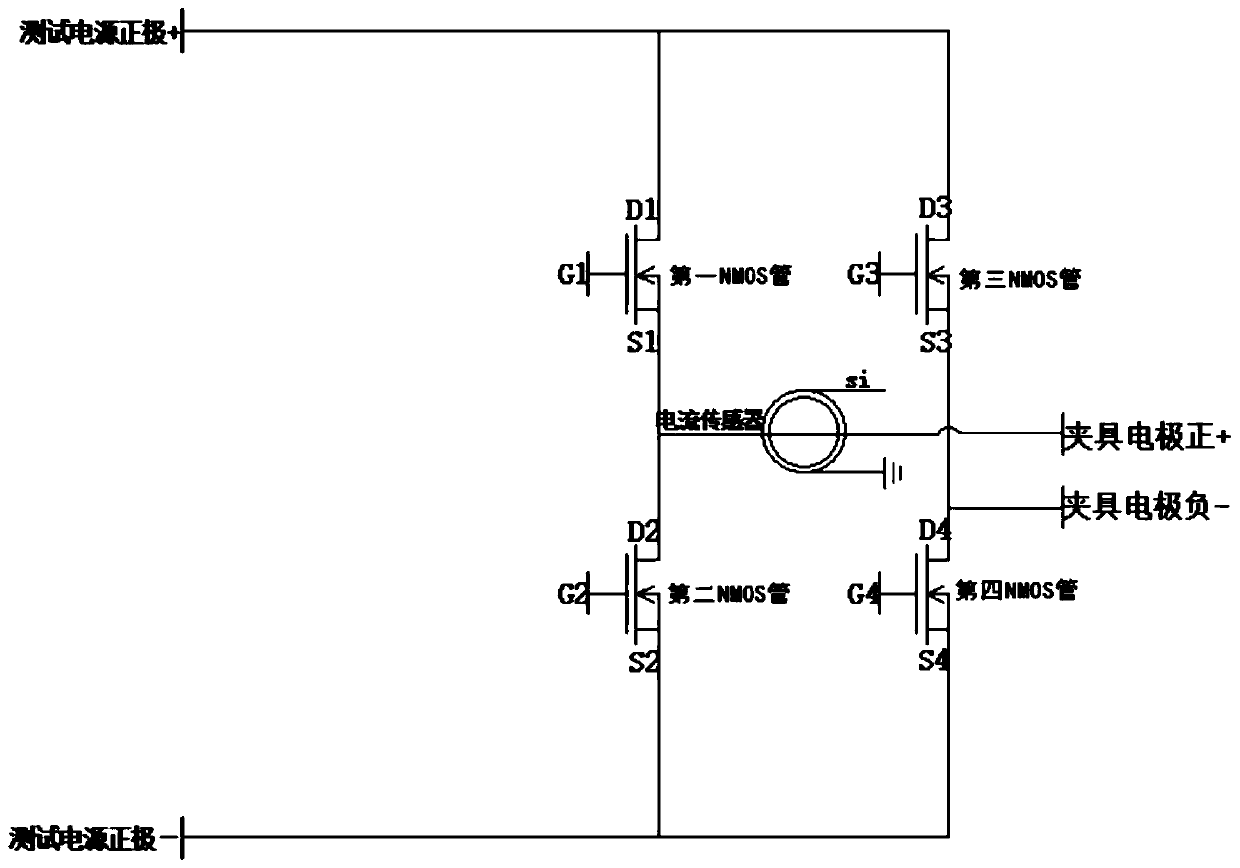

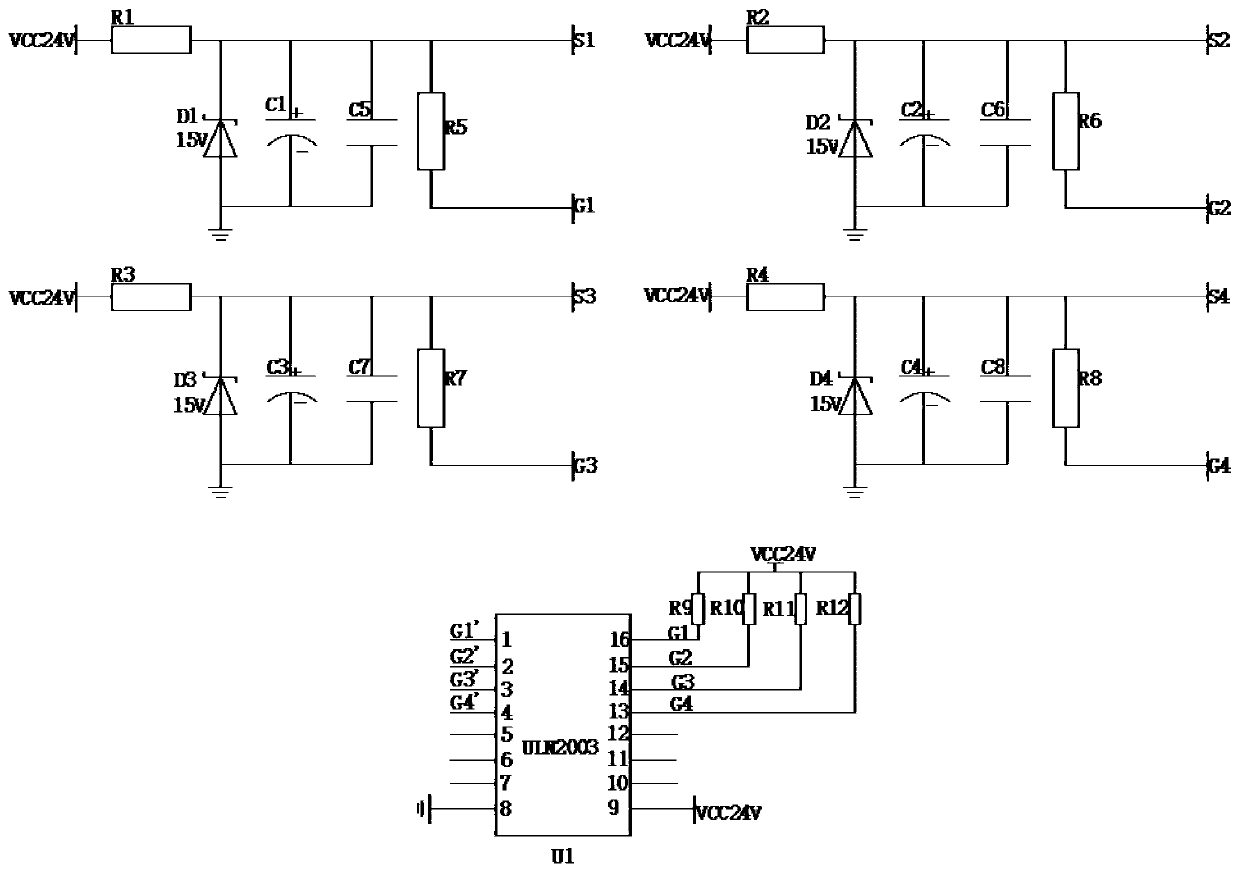

[0033] Such as Figure 2-4 As shown, the MOS transistor driving circuit is an H bridge circuit including a first NMOS transistor, a second NMOS transistor, a third NMOS transistor and a fourth NMOS transistor, the drain D1 of the first NMOS transistor, the drain of the third NMOS transistor The drain D3 is used as the positive power supply terminal of the H bridge, the source S1 of the first NMOS transistor is electrically connected to the drain D2 of the second NMOS transistor, the source S3 of the third NMOS transistor is connected to the drain of the fourth NMOS transistor Pole D4 is electrically connected, and the source S2 of the second NMOS tube and the source S4 of the fourth NMOS tube are used as the negative terminal of the power supply of the H bridge; the positive terminal of the ...

Embodiment 2

[0044] This embodiment 2 is a method for testing LED lamps based on the test system provided in embodiment 1, such as Figure 5 As shown, the specific steps are as follows:

[0045] S1. When the LED lamp to be tested is installed on the test fixture, the signals output by the single-chip microcomputers G1', G4' are low-level drive signals, and the signals output by the single-chip microcomputers G2', G3' are high-level drive signals;

[0046] S2. After the driving signal output by the single-chip microcomputer is reversed by the ULN2003 Darlington tube and the driving capability is enhanced, it directly drives the first MOS tube and the fourth NMOS tube to turn on, and the second MOS tube and the third NMOS tube remain off; therefore, the LED lights The test current flows in from the positive pole of the test fixture and flows out from the negative pole;

[0047] S3. The current sensor Si detects the current value of the test loop, and judges whether the current value is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com