Injection device and injection method

A technology of injection device and injection agent, which is applied in the direction of injection device, injection device, liquid injection device, etc., and can solve the problems that injection agent is difficult to enter and objects suck air bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

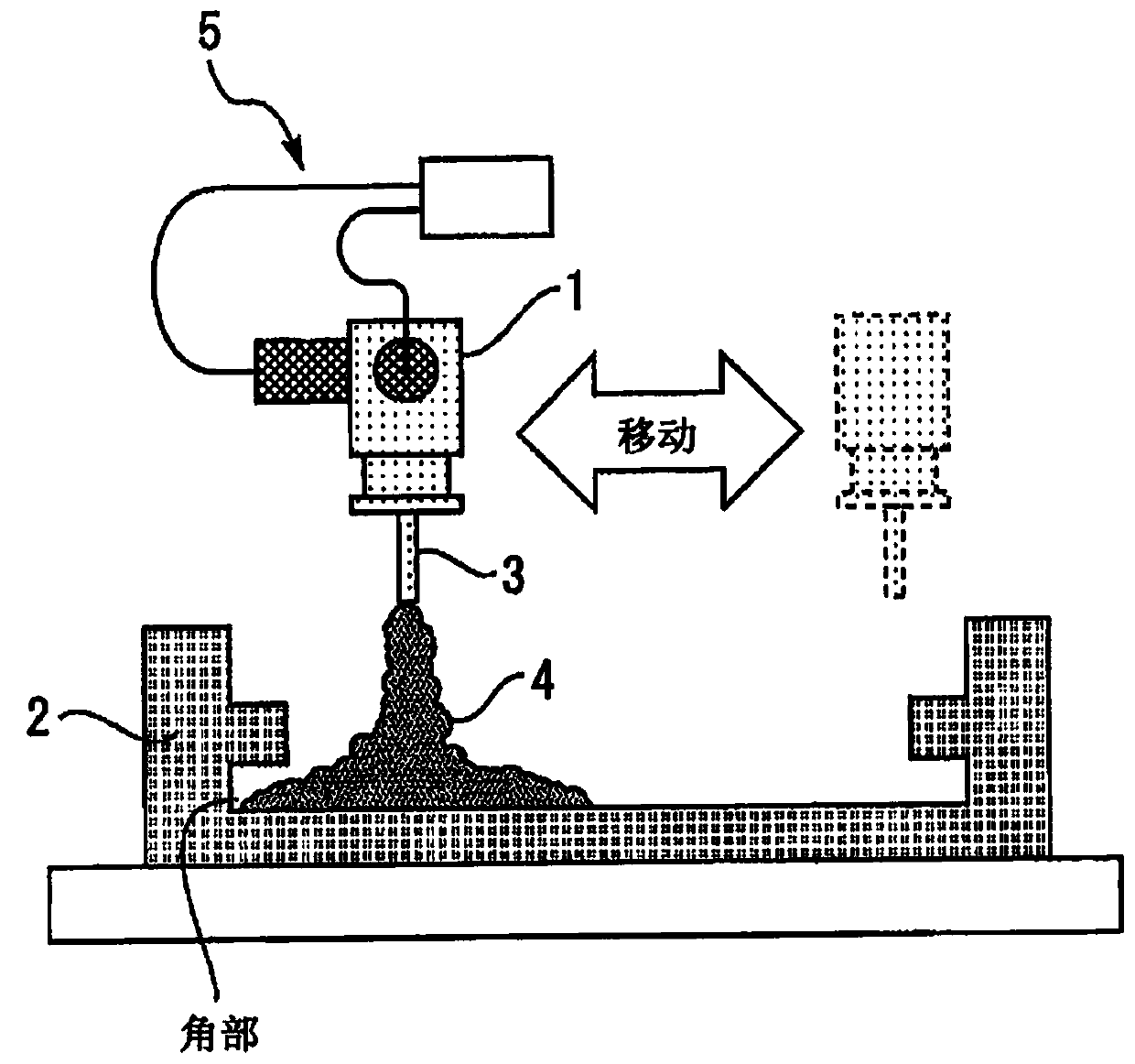

[0018] figure 1 It is a sectional view showing the injection device according to Embodiment 1. The injection nozzle 1 is arranged above the target device 2 , and injects the injection agent 4 discharged from the nozzle head 3 into the target device 2 . When the injection agent 4 is injected, the vibration generator 5 vibrates the injection nozzle 1 in multiple directions. For example, the frequency of the vibration of the injection nozzle 1 is less than or equal to 1000 Hz, and the amplitude is less than or equal to 1 mm.

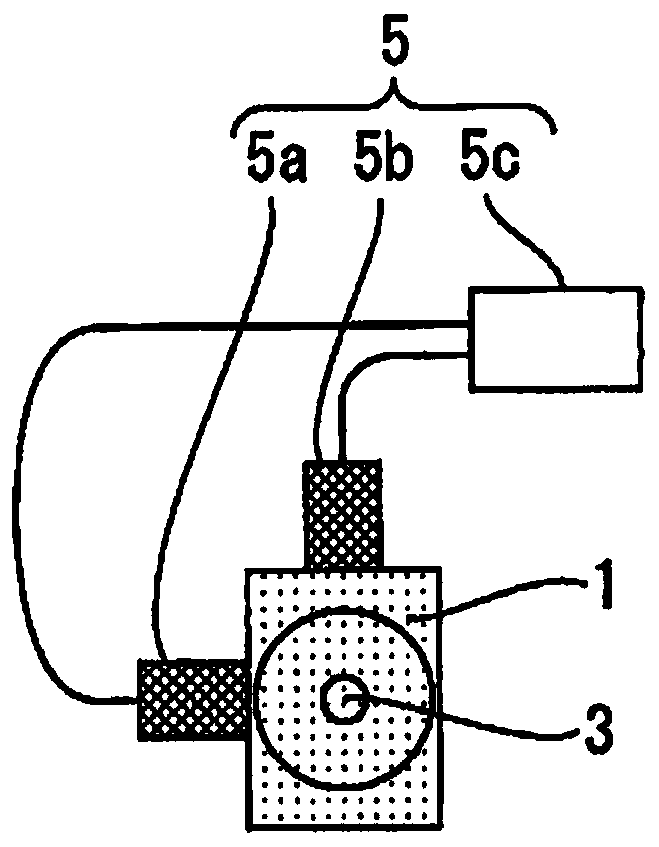

[0019] figure 2 It is a bottom view showing the injection nozzle according to the first embodiment. The vibration generating device 5 includes a plurality of vibration generators 5a, 5b provided at a plurality of places on the side of the injection nozzle 1, and an amplifier 5c that drives the vibration generators 5a, 5b. Here, two vibration generators 5a, 5b are installed on the side surfaces of the injection nozzle 1, and the injection nozzle 1 vibra...

Embodiment approach 2

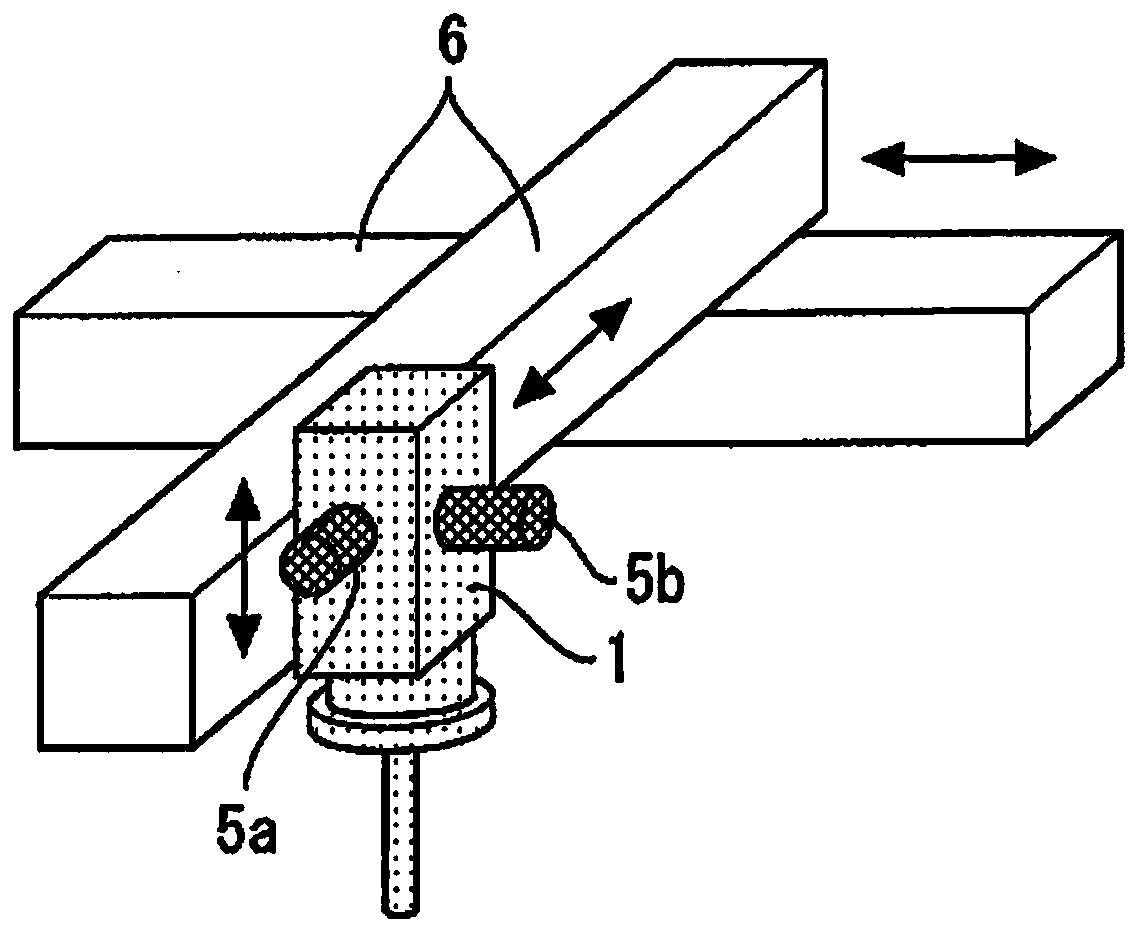

[0025] Figure 5 It is a perspective view showing the injection device according to Embodiment 2. The two injection nozzles 1 are arranged side by side on the orthogonal axis 6 . In addition, the number of injection nozzles may also be greater than or equal to three. A plurality of vibration generators 5a, 5b are provided in each of the plurality of injection nozzles 1 . By ejecting the injection agent 4 from the plurality of injection nozzles 1 at the same time, it is possible to inject a large amount of the injection agent 4 at once.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com