On-line canopy height detection method for automatic control of header height of harvesting machine

A technology for canopy height and harvesting machinery, applied in general control systems, harvesters, control/regulation systems, etc., can solve problems such as low measurement accuracy and reliability, easy interference of ultrasonic waves, and inability to detect crop canopy heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is based on Figure 1 to Figure 5 The specific embodiment of the present invention is further described:

[0039] This embodiment takes the wheat field as the object, and is used for the canopy height online detection method of the automatic control of the height of the harvesting mechanical header, and the steps are as follows figure 1 As shown, the details are as follows:

[0040] (1) Data preprocessing:

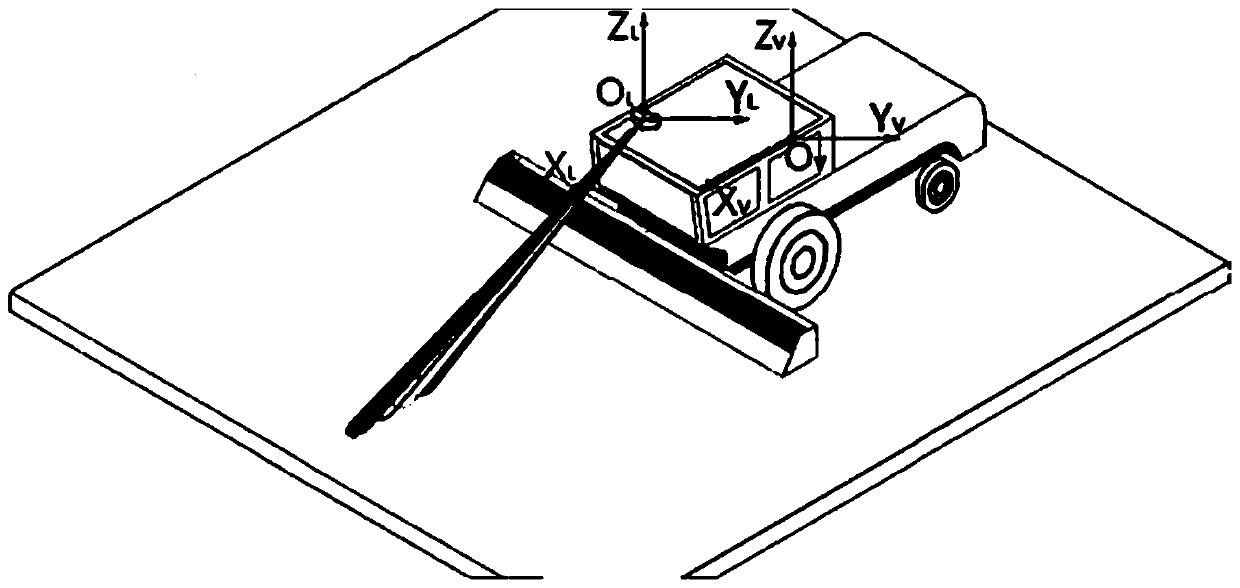

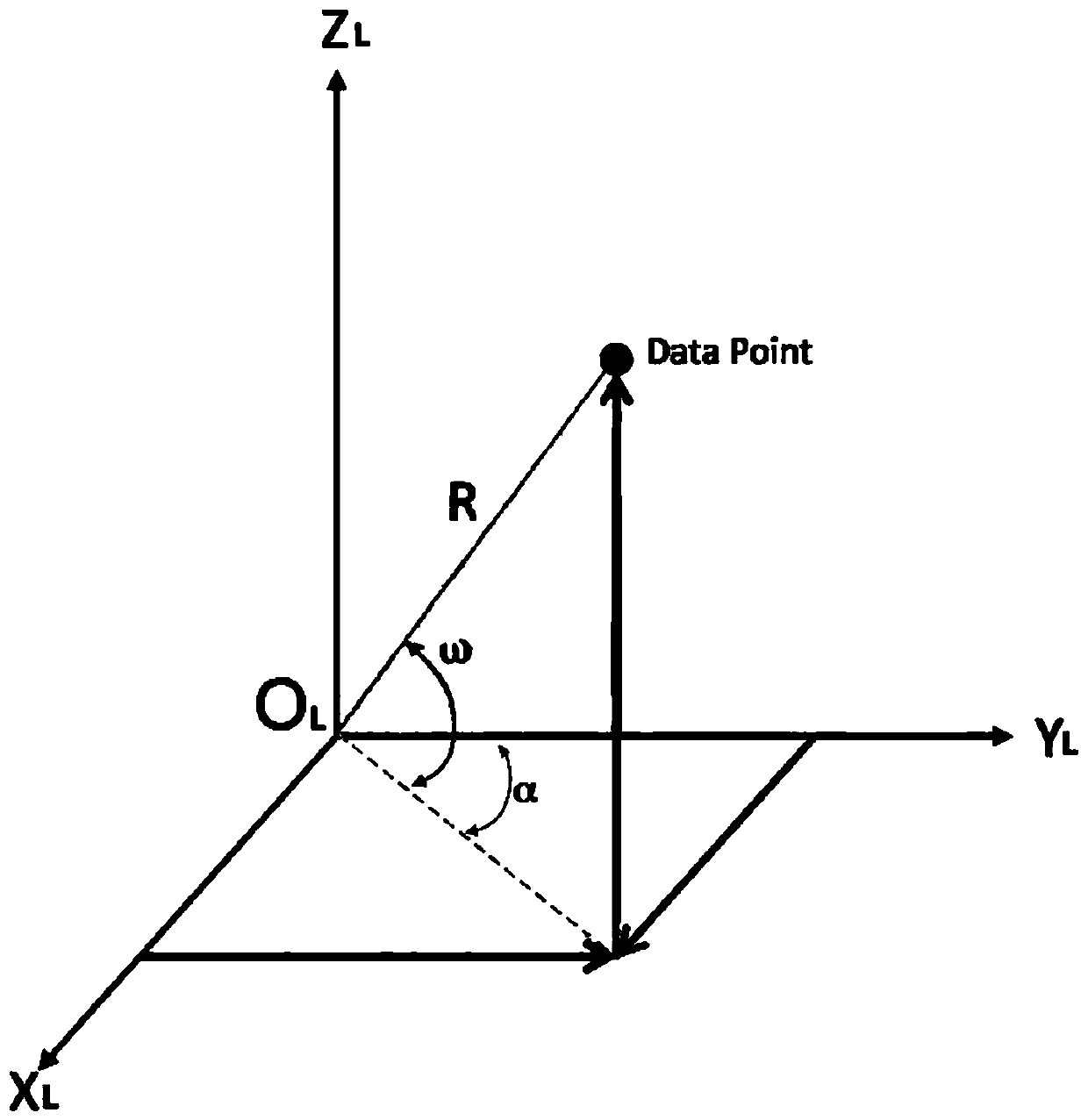

[0041] The laser radar is installed in the middle of the harvester through the bracket, and the laser radar coordinate system O is established respectively. L -X L Y L Z L and harvester coordinate system O V -X V Y V Z V ,Such as figure 2 shown. Obtain the point cloud data of the crops in front of the harvester through the laser radar, and convert the point cloud data output by the laser radar from polar coordinates to the laser radar Cartesian coordinate system O L -X L Y L Z L Inside, the radar coordinate system O L -X L Y L Z L T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com