Moving screw full-grouting sleeve rebar connector

A steel connector and full grouting technology, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as strong construction concealment, deformation, and difficult quality control, so as to avoid inconvenience and construction hidden dangers. Application prospects wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

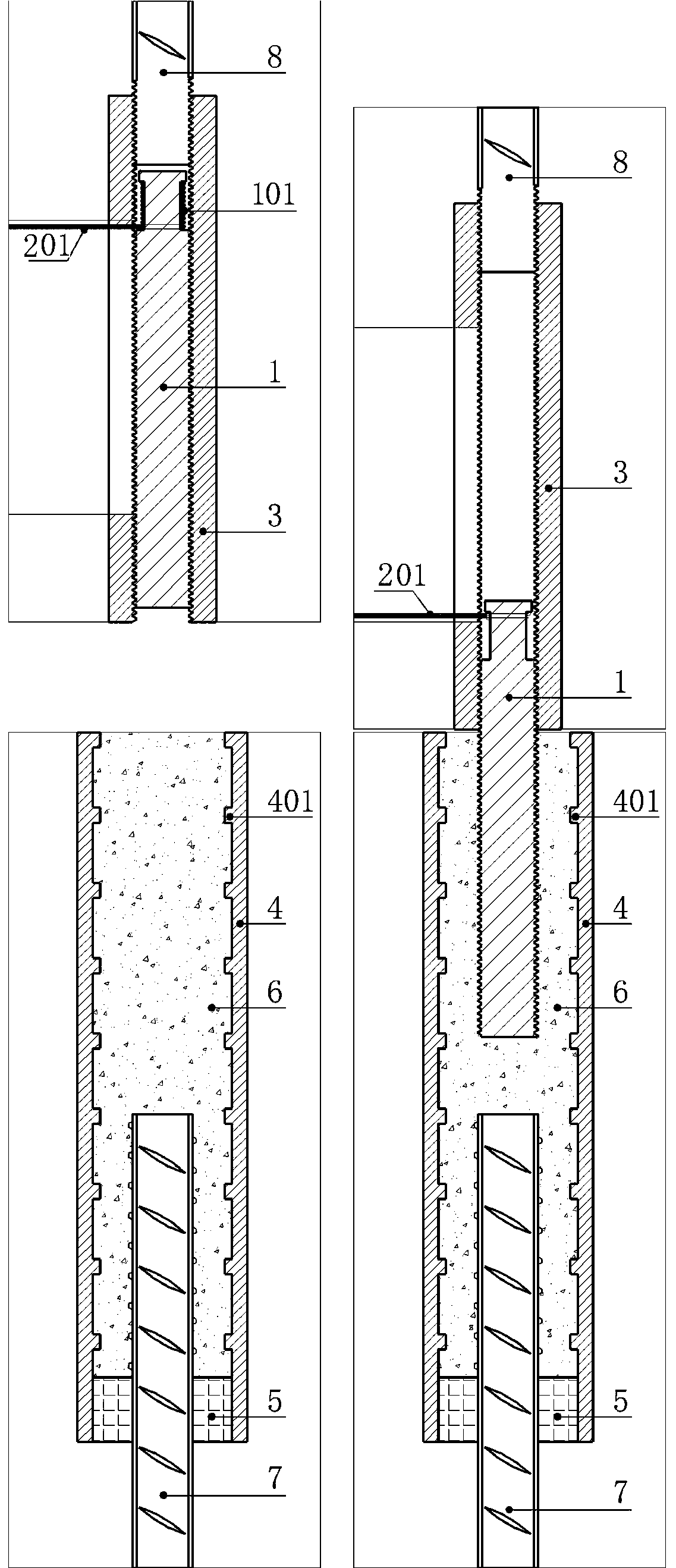

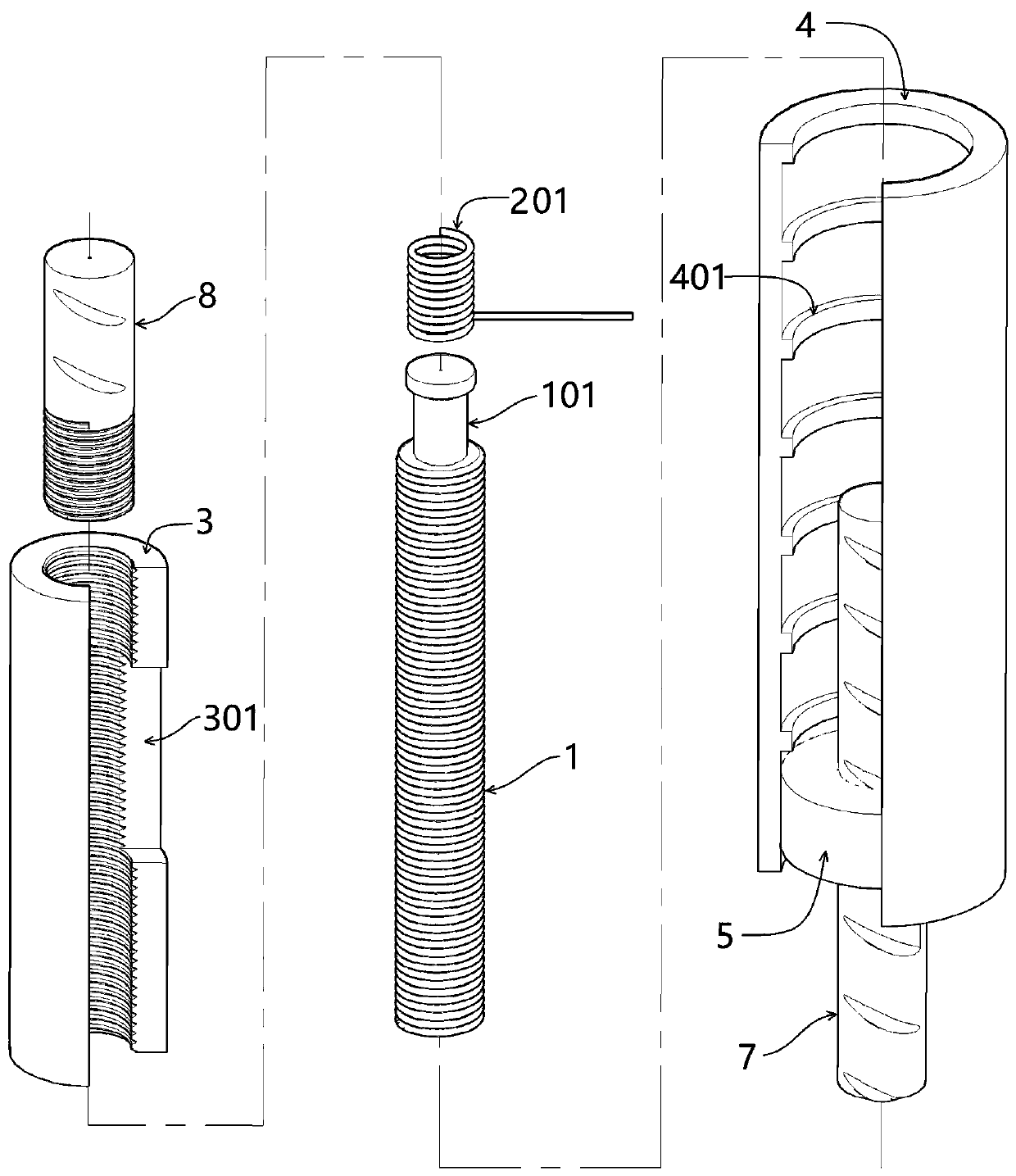

[0020] Such as figure 1 and figure 2 As shown, a specific embodiment of the present invention, connecting steel bar one 7 and steel bar two 8, is characterized in that: comprising moving screw 1, steel wire rope 201, connecting sleeve 3, full grouting sleeve 4, sealing match 5 and cement-based slurry Material 6; the moving screw 1 and the connecting sleeve 3 form a connector male joint, one end of the connecting sleeve 3 is connected with the steel bar 2 8 by a threaded pair, and the other end of the connecting sleeve 3 is connected with the moving screw 1 by a threaded pair; the full grouting sleeve 4 and the sealing match 5 form the female joint of the connector, the reinforcing bar 7 extends into the full grouting sleeve 4, and the sealing match 5 is used to seal between the full grouting sleeve 4 and the reinforcing bar 7.

[0021] The inner wall of the full-grouting sleeve 4 is provided with a circumferentially protruding shear force key 401; the full-grouting sleeve 4 ...

Embodiment 2

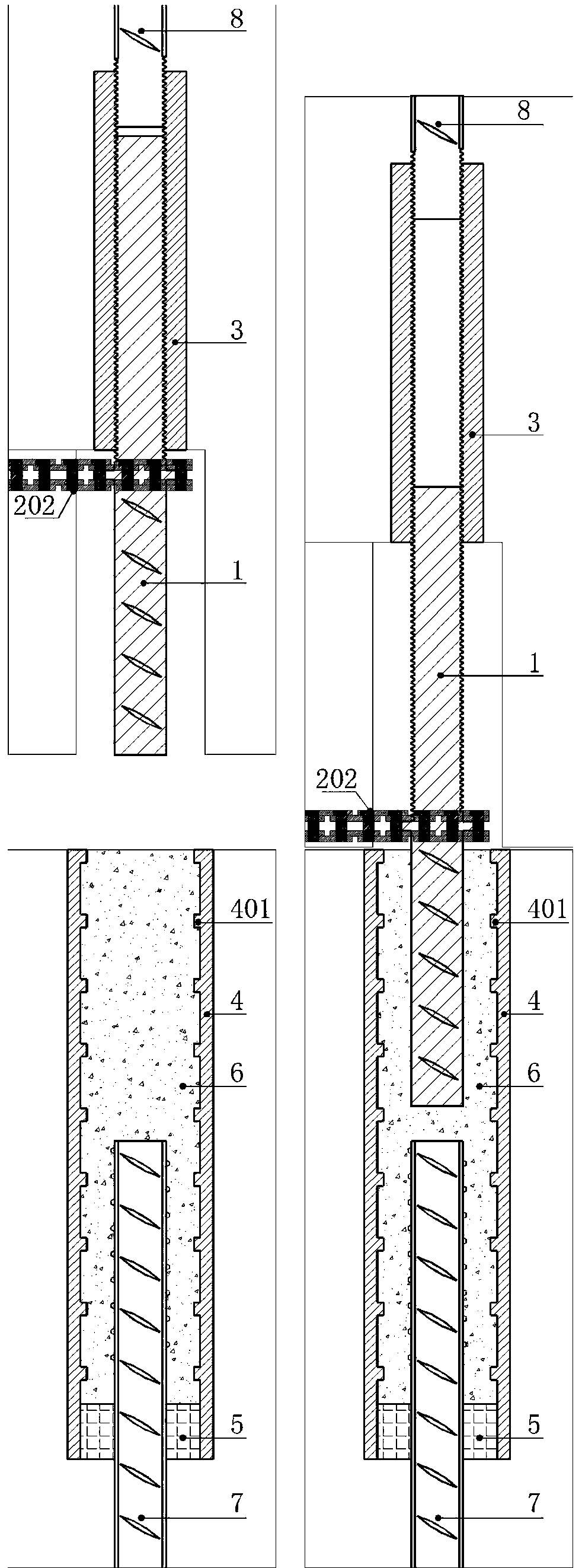

[0024] Such as image 3 and Figure 4 As shown, a specific embodiment of the present invention, connecting steel bar one 7 and steel bar two 8, is characterized in that: comprising moving screw 1, chain 202, connecting sleeve 3, full grouting sleeve 4, sealing match 5 and cement-based slurry Material 6; the moving screw 1 and the connecting sleeve 3 form a connector male joint, one end of the connecting sleeve 3 is connected with the steel bar 2 8 by a threaded pair, and the other end of the connecting sleeve 3 is connected with the moving screw 1 by a threaded pair; the full grouting sleeve 4 and the sealing match 5 form the female joint of the connector, the reinforcing bar 7 extends into the full grouting sleeve 4, and the sealing match 5 is used to seal between the full grouting sleeve 4 and the reinforcing bar 7.

[0025] The inner wall of the full-grouting sleeve 4 is provided with a circumferentially protruding shear force key 401; the full-grouting sleeve 4 is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com