A Construction Technology of Immersed Tube Compaction Pile Using Built-in Tamper for Bottom Ramming

A construction process and technology of compacting piles, which are applied in sheet pile walls, soil protection, infrastructure engineering and other directions, and can solve the problems of small hole diameter, complex construction process and shallow treatment depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] refer to figure 1 , the present embodiment 1 provides a construction technique for sinking tube compaction piles using a built-in rammer for bottom tamping, which utilizes construction equipment for construction, and the construction equipment includes a pile pipe 1 and a pile point 2 at the bottom thereof, and also includes hydraulic pressure Pile driver and the replacement structure 5 at the inner bottom of the pile pipe 1. The hydraulic pile driver 1 is an existing equipment, which mainly includes a main engine 8, a hydraulic pipeline 7, a support frame 6 and a hydraulic hammer 4 in the pile pipe. The construction process includes the following steps:

[0041] Step 1, measure the specific pile position, and place the pile tube with the pile point at the bottom at the corresponding pile position;

[0042] Step 2, using the built-in hammer to ram the inner bottom of the pile pipe, the pile tip sinks under force, and then drives the pile pipe to sink;

[0043] Step 3....

Embodiment 2

[0058] The location of the implementation project is located in a loess area in the central and western regions. The pre-constructed buildings are 30-storey residential buildings. The self-weight collapsible Class III site has a collapsible loess layer thickness of 32m.

[0059] In order to eliminate all the collapsibility in the foundation, it is required that the length of the compaction pile is 32m, the diameter of the hole is 600mm, the diameter of the pile is 800mm, and the weight of the pile hammer is 12t.

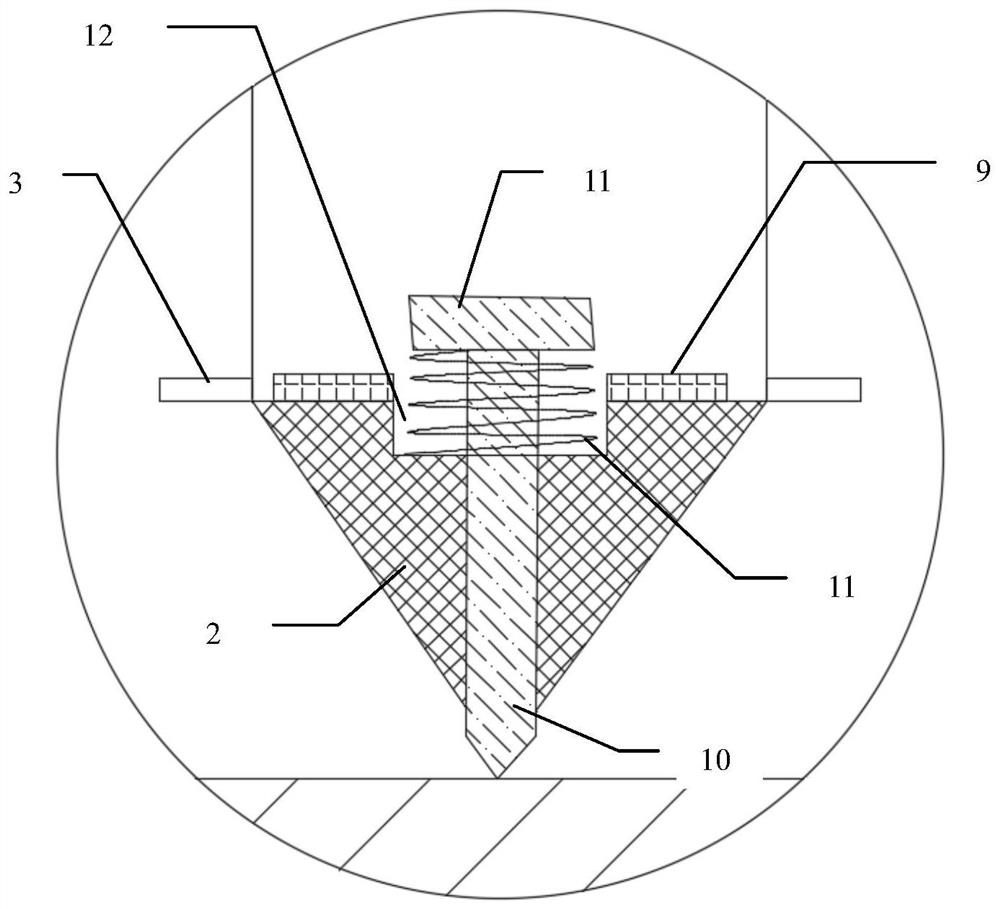

[0060] refer to figure 2 and image 3 , this embodiment 2 provides a construction process for super-long and large-diameter immersed tube compaction piles in collapsible loess areas using a built-in rammer for bottom tamping. It uses immersed tube equipment for construction, and the immersed tube equipment is the same as that of the embodiment 1. The difference is that its replacement structure includes replacement ring 9, replacement nail 10 and nail cap 11. A cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com