River bed water intake structure for hydropower station forward water taking

A technology for water intakes and hydropower stations, applied in hydropower stations, hydropower, hydraulic engineering, etc., can solve the problems of sediment deposition, affecting the safety of water diversion channels and downstream turbines, and it is difficult to discharge the sand sluice, so as to reduce sedimentation , Guarantee smooth flow and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

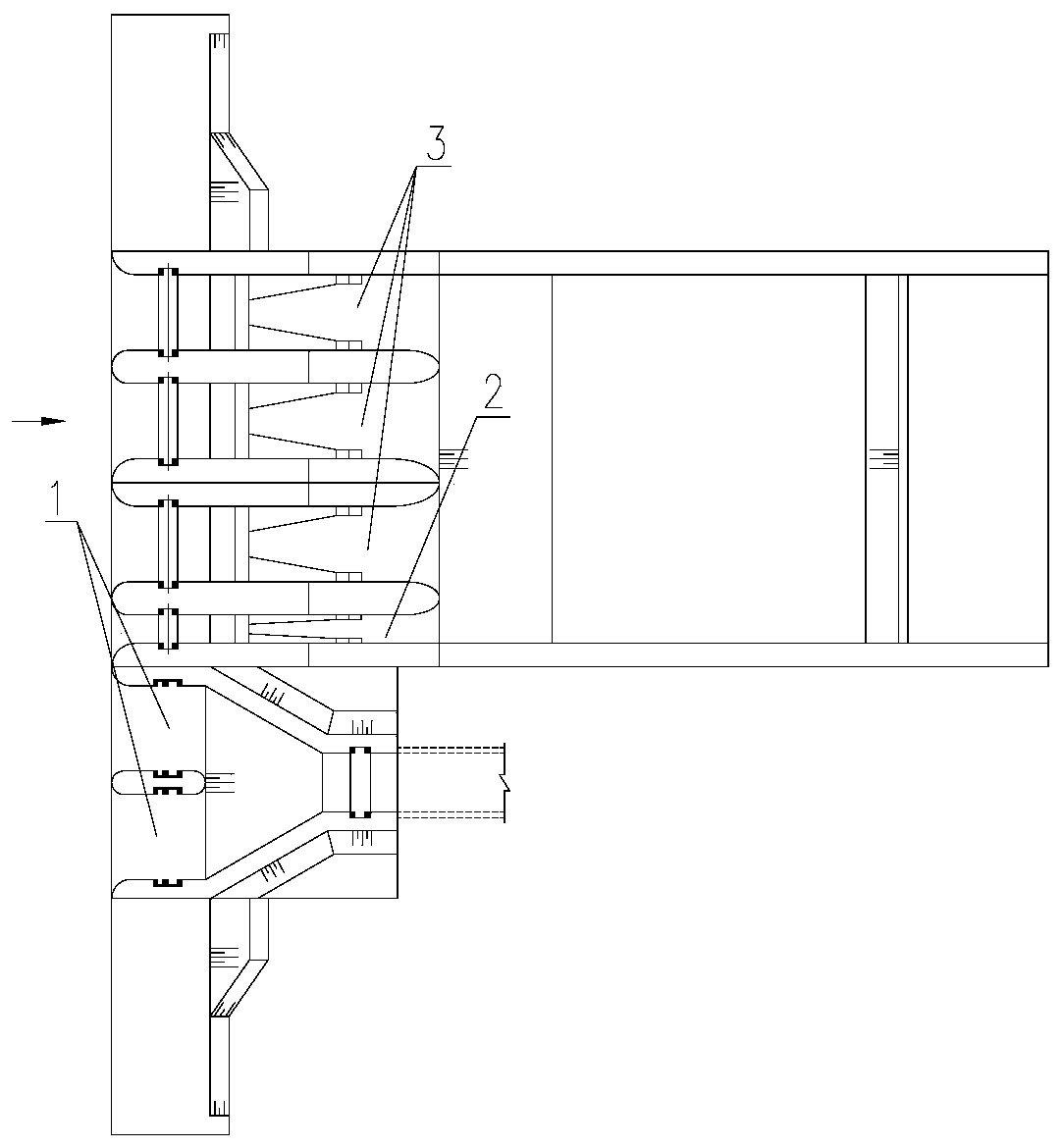

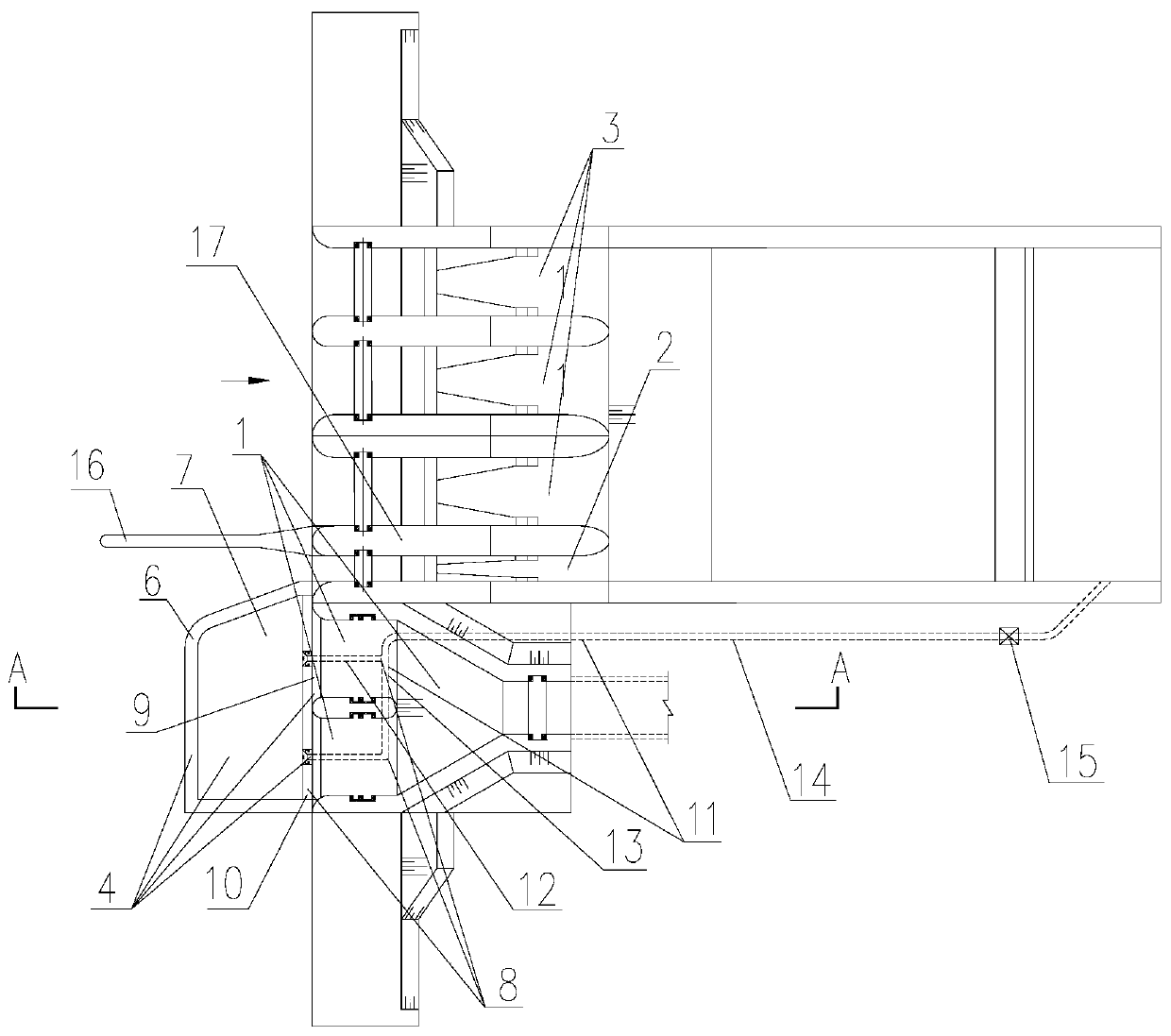

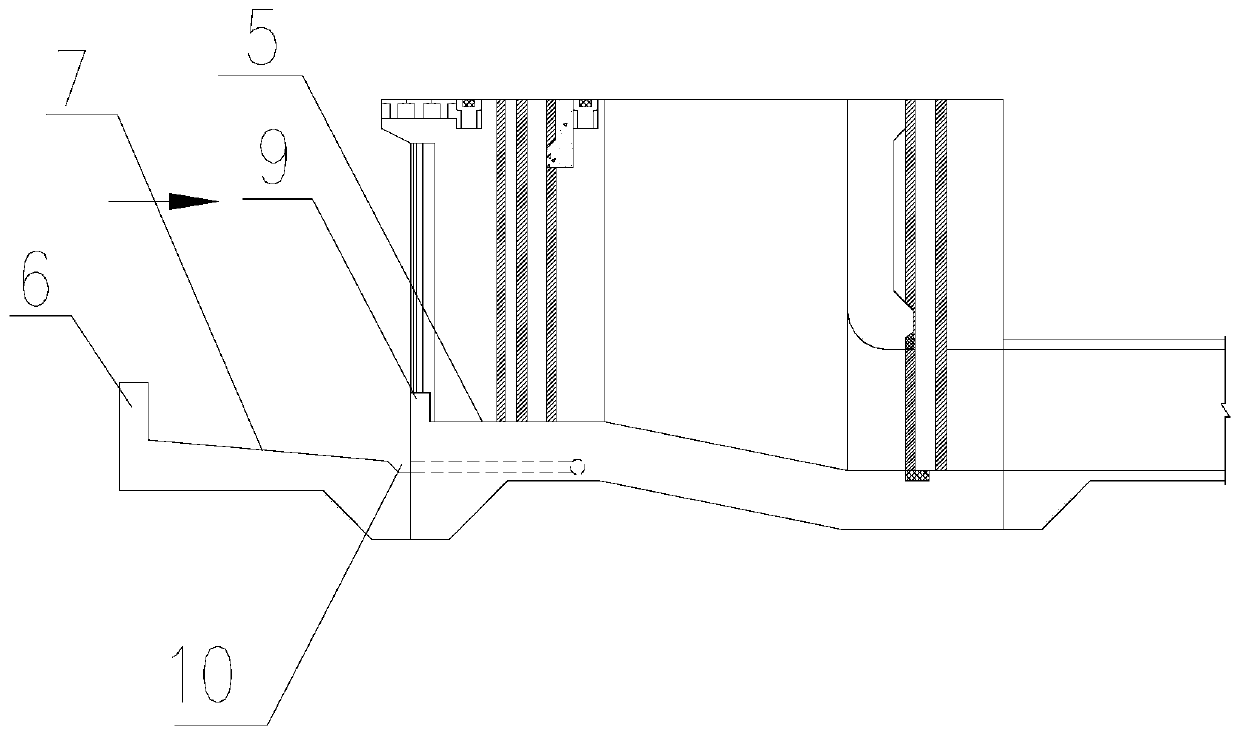

[0020] Such as figure 2 , image 3 Shown is a riverbed water intake structure for forward water intake of hydropower stations that can effectively solve the problem of river sediment deposition on the upstream side of the water intake provided by the present invention. The river bed water intake structure includes a water intake 1, a sand flushing gate 2 and a flood discharge gate 3 arranged in sequence along the width direction of the river, and the axis 3 of the water intake 1 is connected to the axis of the sand flushing gate 2 and the flood discharge gate 3 3 to be consistent, the structure of the river bed water intake also includes a pre-sand-blocking settlement discharge system 4, and the pre-sand-blocking settlement discharge system 4 is arranged in the riverbed on the upstream side of the water intake 1 and enters the water intake 1 The preceding water flow removes the large-grained sand and stones therein through the described pre-sand-blocking settlement discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com