A construction method for aerial connection of steel pipe arch rib segments

A construction method and technology of steel pipe arch ribs, applied in arch bridges, buildings, bridge construction, etc., can solve the problems that locking devices cannot be dismantled and reused, flange plate 05 deflected bolts are installed and constructed, and concrete jacking construction is blocked, etc. Achieve the effect of convenient disassembly and reuse, strong applicability and economy, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

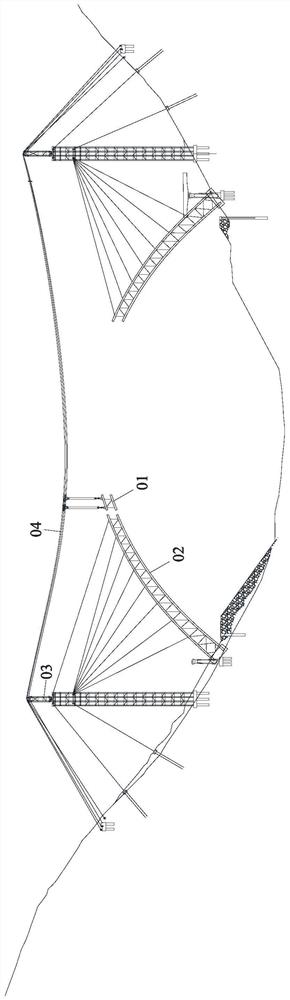

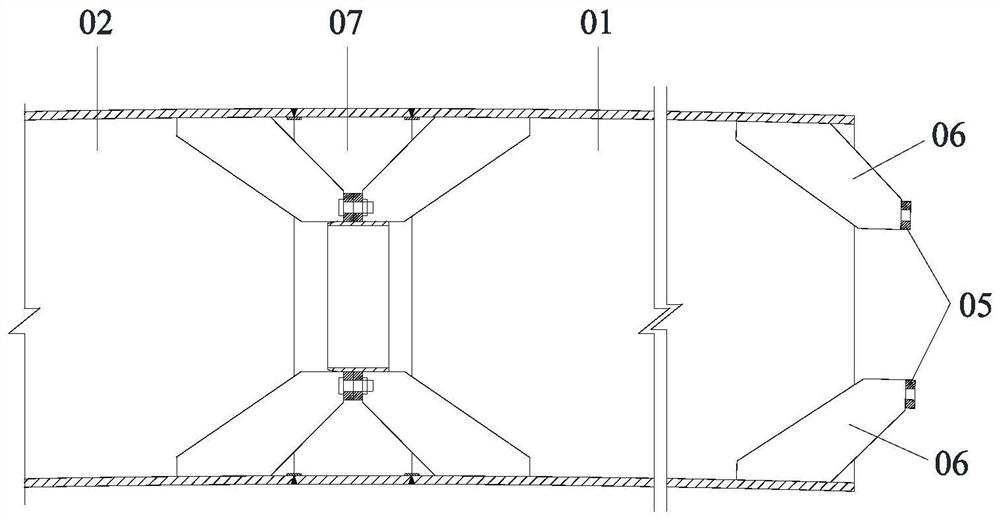

[0048] Such as Figure 3-8 As shown, a construction method for aerial connection of a steel pipe arch rib segment according to the present invention comprises the following steps:

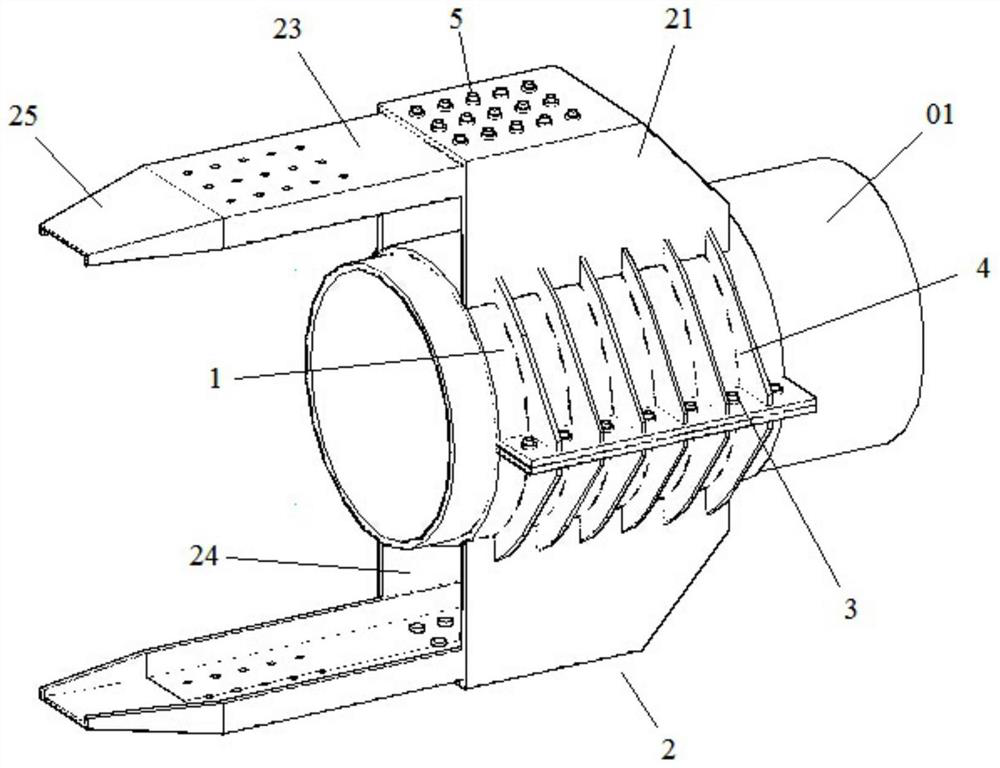

[0049] A. If Figure 3-6 As shown, two semi-circular hoop steel plates 1 of the same size and shape are installed at the end of the steel pipe of the arch rib section 01, and the contact surface between the hoop steel plate 1 and the steel pipe of the arch rib section 01 Anti-skid paint is sprayed on the contact surface with the installed arch rib 02 steel pipe;

[0050] B. Ear plates are provided at both ends of each hoop steel plate 1, and the lug plates after the cooperation of the two hoop steel plates 1 are bolted together by several first bolts 3, so that the two hoop steel plates 1 embrace Close to the circumference of the steel pipe of the arch rib segment 01;

[0051] Such as image 3 As shown, the steel pipe of the arch rib segment 01 needs to be connected with the first limit seat 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com