Making process of gold silk skin-nourishing quilt

A production process and silk technology, which is applied in the cleaning/classification of cocoons, silk fiber production and application, etc., can solve the problem of small black spots or small tendons of impurities, low quilt flexibility and service life, affecting users. Continue to use and other problems to achieve the effect of shortening the degreasing time, ensuring the service life and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

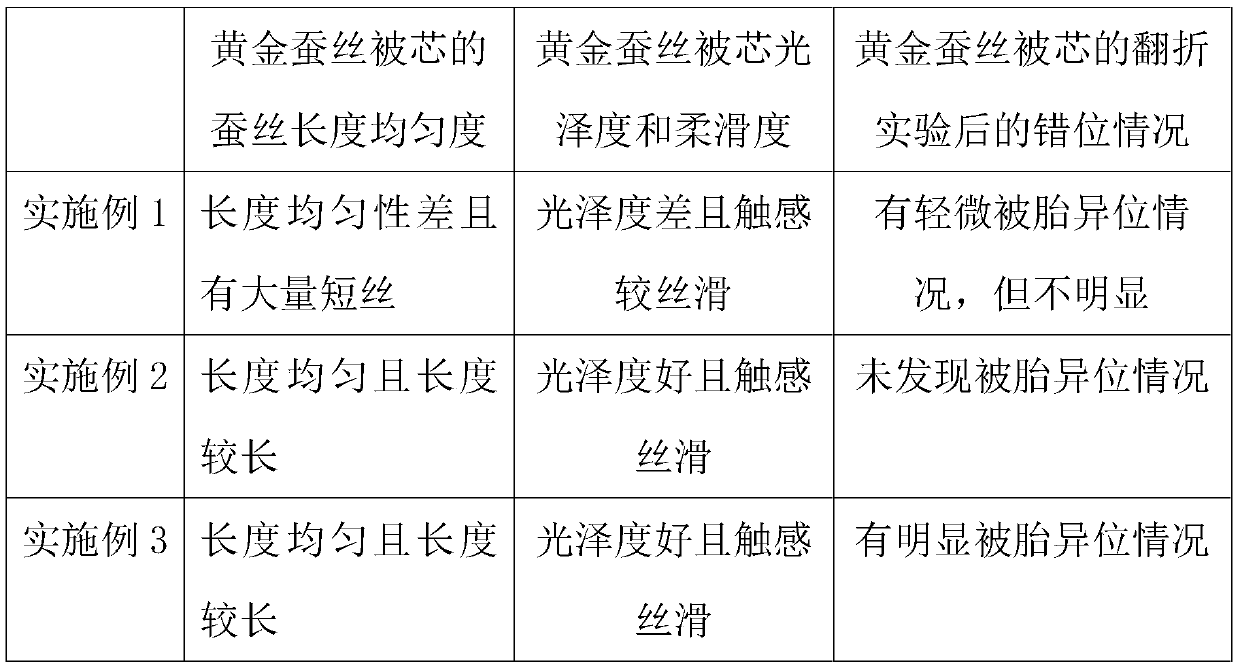

Embodiment 1

[0030] The invention provides a manufacturing process of golden silk skin nourishing quilt, the specific steps are as follows:

[0031] a) cocoon selection: select golden silkworm cocoons without obvious damage or crack;

[0032] b) Cocoon cooking:

[0033] ①Infiltration: Using the temperature difference infiltration method, first put the cocoons into the high-temperature infiltration part. In the infiltration process, the temperature of the infiltration part is set to 100 °C, and the steam pressure is 0.05 kg / m 2 , so that the steam and the air in the cocoon cavity are replaced, and then the cocoon is moved to the low-temperature water of about 60°C. Due to the temperature drop, the steam and air in the cocoon cavity shrink sharply after being cooled, so that the pressure inside and outside the cocoon cavity is different, reaching the cocoon layer the purpose of infiltration;

[0034] ②Steaming: Cooking the infiltrated cocoon, the main function is to make the cocoon cavity ...

Embodiment 2

[0044] The invention provides a manufacturing process of golden silk skin nourishing quilt, the specific steps are as follows:

[0045] a) cocoon selection: select golden silkworm cocoons without obvious damage or crack;

[0046] b) Cocoon cooking:

[0047]①Impregnation: Immerse the cocoon in warm water to infiltrate the cocoon layer and form a water film on the outside of the cocoon layer to enhance the water passage performance and improve the anti-boiling ability. The duration is about 2-4 minutes;

[0048] ②Infiltration: Using the temperature difference infiltration method, first put the cocoons into the high-temperature infiltration part. In the infiltration process, the temperature of the infiltration part is set to 100 ℃, and the steam pressure is 0.05 kg / m 2 , so that the steam and the air in the cocoon cavity are replaced, and then the cocoon is moved to the low-temperature water of about 60°C. Due to the temperature drop, the steam and air in the cocoon cavity shri...

Embodiment 3

[0059] The invention provides a manufacturing process of golden silk skin nourishing quilt, the specific steps are as follows:

[0060] a) cocoon selection: select golden silkworm cocoons without obvious damage or crack;

[0061] b) Cocoon cooking:

[0062] ①Impregnation: Immerse the cocoon in warm water to infiltrate the cocoon layer and form a water film on the outside of the cocoon layer to enhance the water passage performance and improve the anti-boiling ability. The duration is about 2-4 minutes;

[0063] ②Infiltration: Using the temperature difference infiltration method, first put the cocoons into the high-temperature infiltration part. In the infiltration process, the temperature of the infiltration part is set to 100 ℃, and the steam pressure is 0.05 kg / m 2 , so that the steam and the air in the cocoon cavity are replaced, and then the cocoon is moved to the low-temperature water of about 60°C. Due to the temperature drop, the steam and air in the cocoon cavity shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com