Nickel-based complex, and preparation method and application thereof

A complex, nickel-based technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve problems such as lack, and achieve the effects of cost saving, energy saving, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

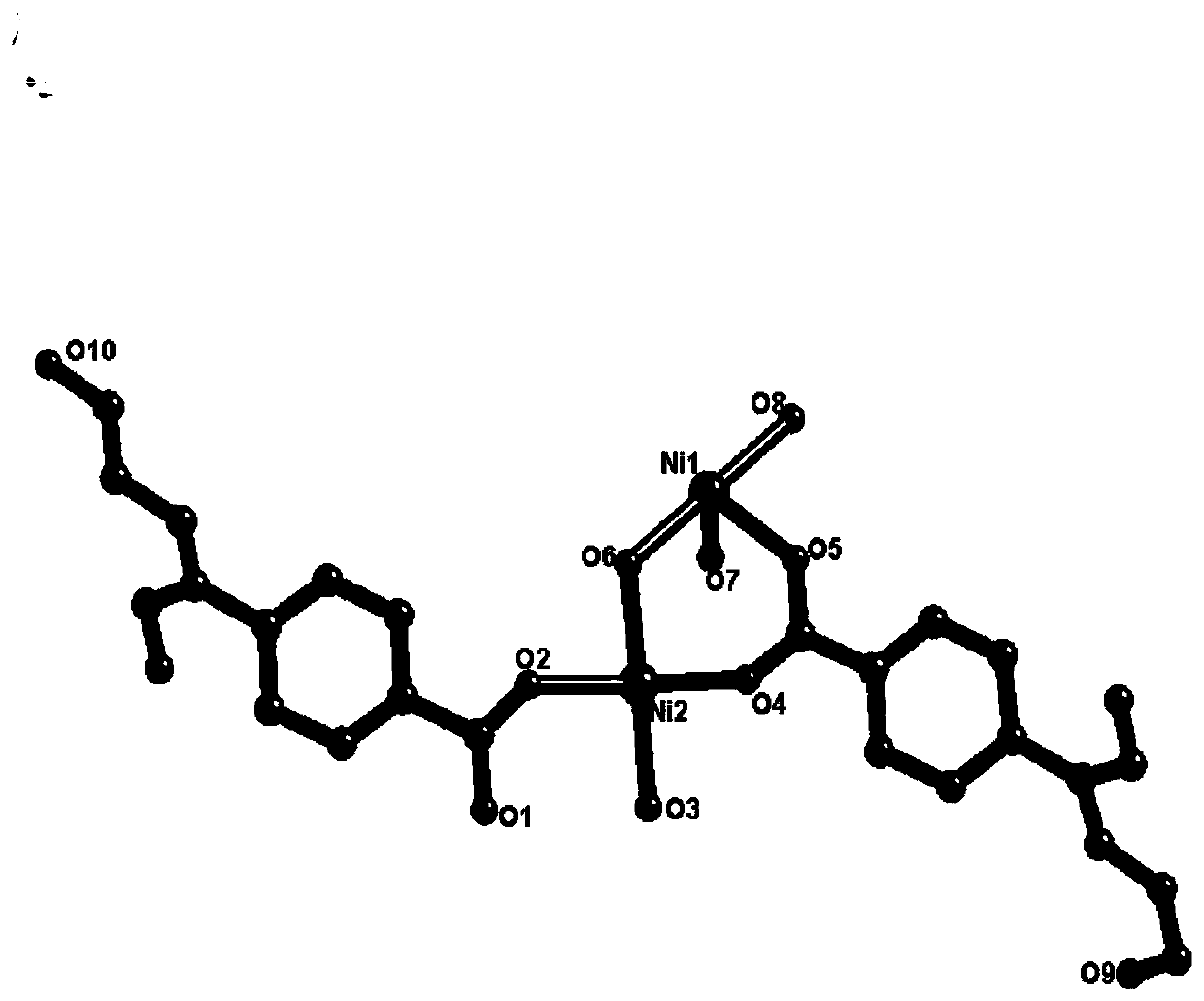

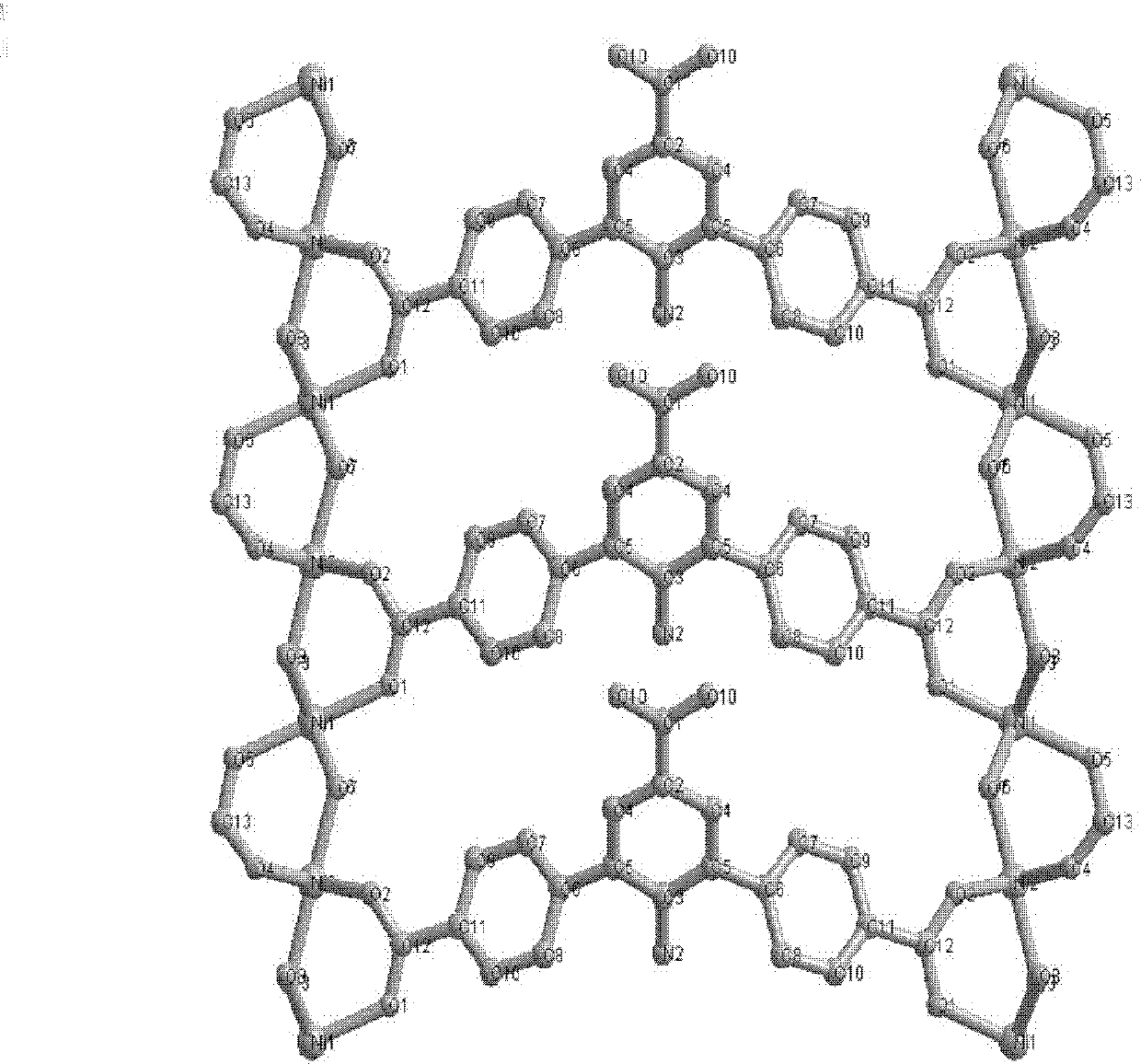

[0035] A preparation method of a nickel-based complex, comprising the following steps:

[0036] A. Accurately weigh 0.0050g, 0.0133mmol of 2-amino[1,1:3,1-terphenyl]-4,4,5-tricarboxylic acid (H 3 attca) ligand and 0.0500g, 0.138mmol of nickel nitrate hexahydrate in the reaction vessel, at room temperature, add 2mL of N,N-dimethylformamide and H in the reaction vessel 2 A mixed solvent composed of O, N,N-dimethylformamide and H 2 The volume ratio of O is 1:1;

[0037] B. Put the solution in step A in a glass bottle and store it in a constant temperature blower box at 100°C for 36 hours to obtain a green crystal-like nickel-based complex.

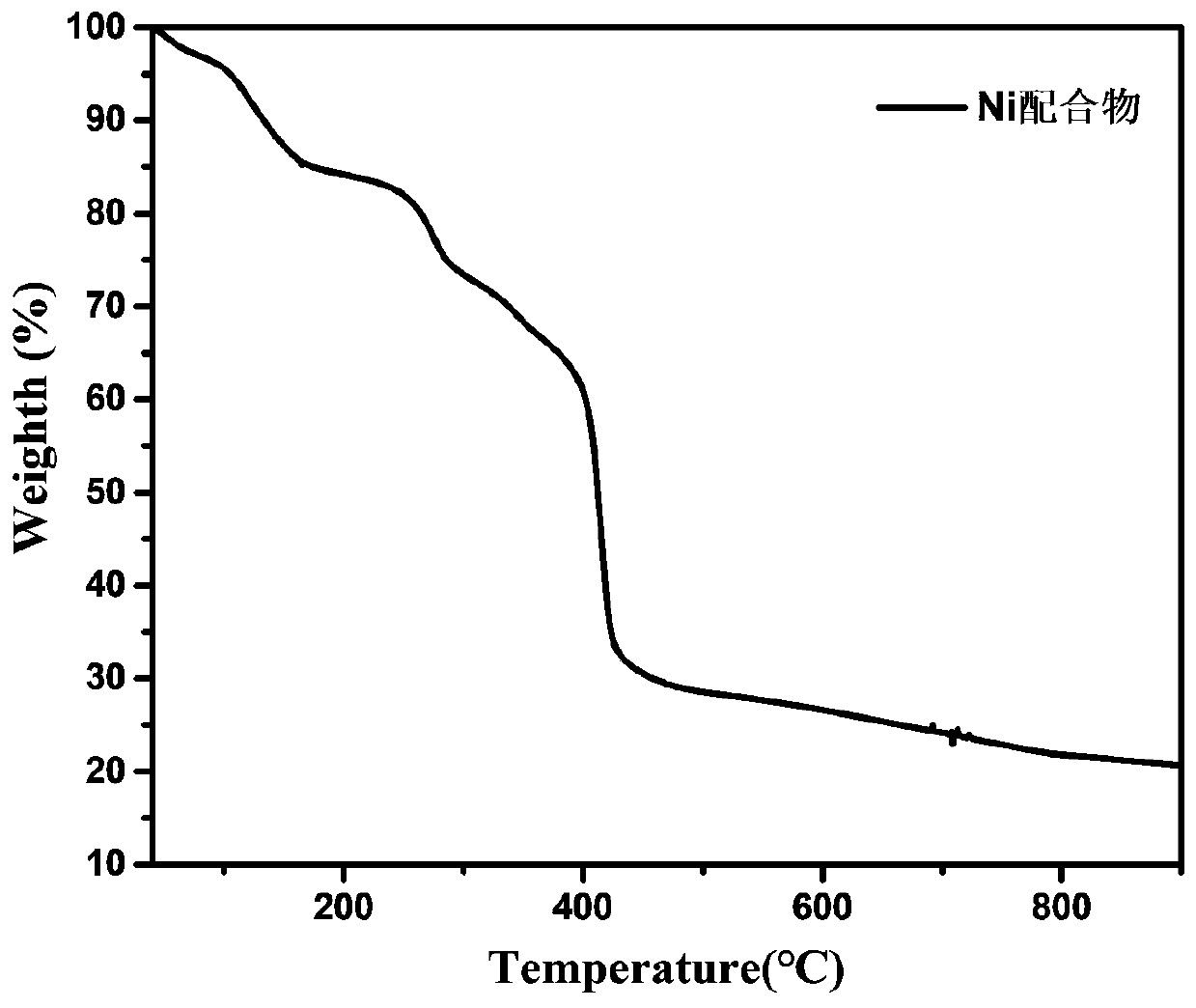

[0038] The resulting green crystalline nickel-based complex

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com