Semitrailer lifting supporting leg

A semi-trailer and outrigger technology, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problems of limited lifting height of outriggers, time-consuming and laborious, outrigger collisions, etc., to improve the accuracy of adjustment, The effect of increasing the contact area and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

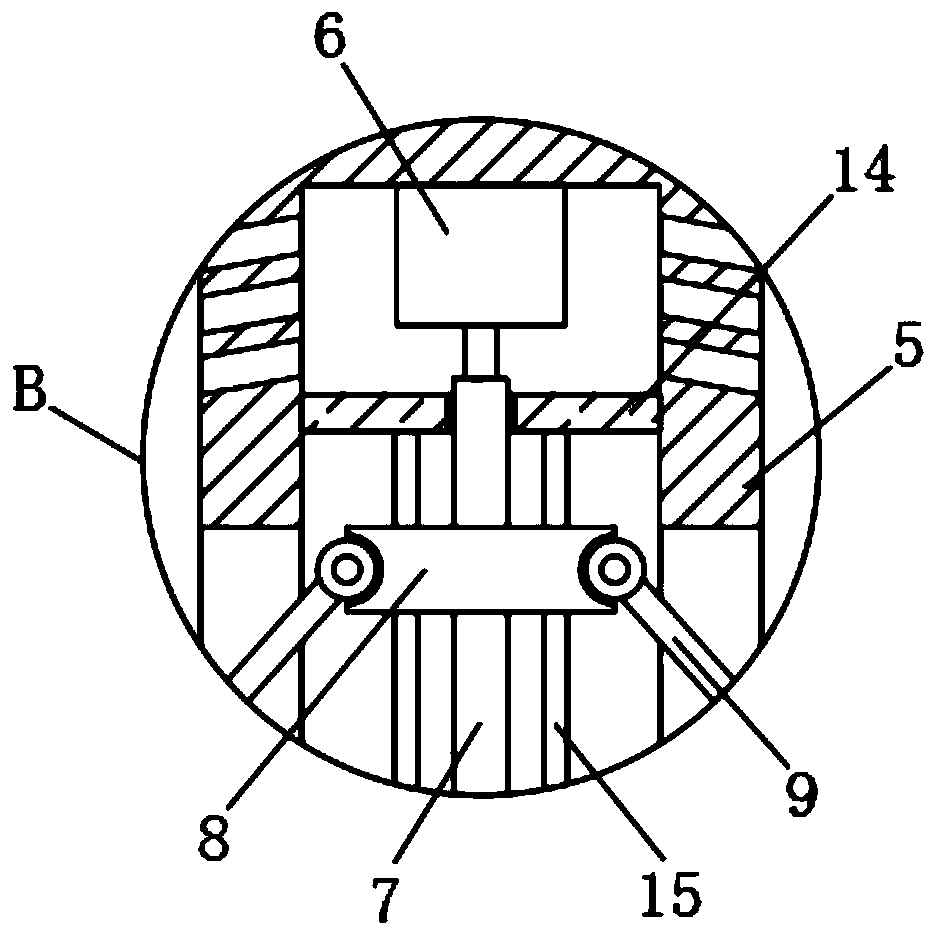

[0025] refer to Figure 1-4 , a lifting leg for a semi-trailer, including a fixed seat 1, the lower end side wall of the fixed seat 1 is connected with a hydraulic telescopic rod 2 through a rotating shaft, a cavity is opened in the fixed seat 1, and the inner wall of the upper end of the cavity is provided with multiple A slanted heat dissipation hole, a plurality of heat dissipation holes are distributed in a rectangular array directly above the positive and negative motor 301, and the heat generated by the positive and negative motor 301 can be dissipated quickly through the heat dissipation holes, thereby ensuring that the positive and negative motor 301 can work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com