Environment-friendly printing device

A printing device, green and environmentally friendly technology, applied in the direction of printing, printing machines, rotary printing machines, etc., can solve the problems that affect paper printing, fail to meet user requirements, and paper dust removal, so as to improve service life and improve coating calendering quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

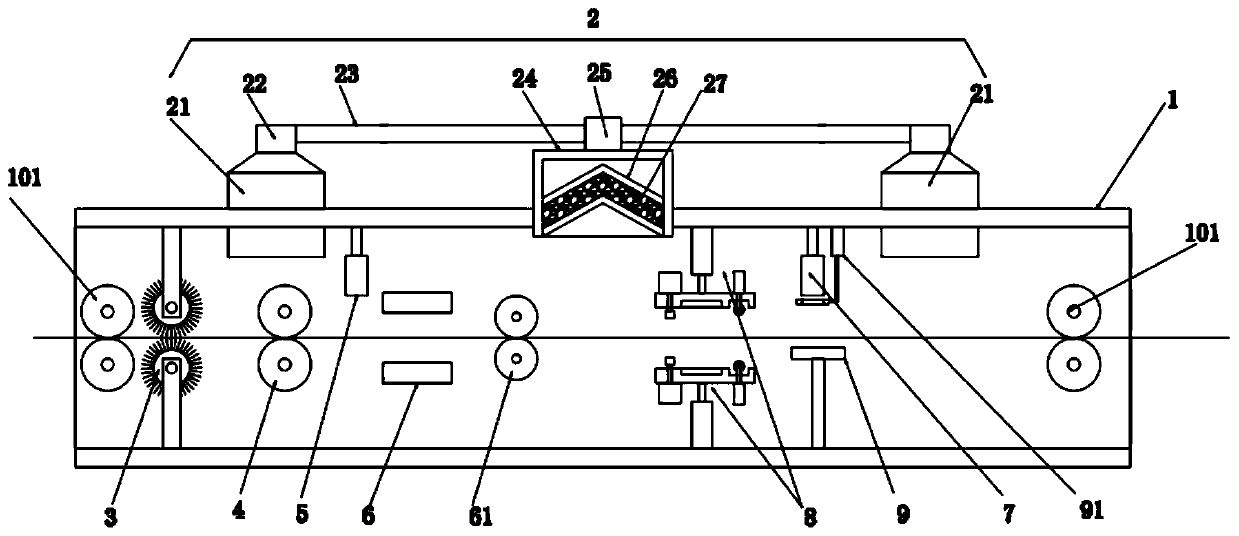

[0032] see Figure 1-4 , in an embodiment of the present invention, a green environmental protection printing device includes a printing body 1 and a set of guide rollers 101 arranged at its feed end and discharge end for guiding paper, the feed end of the print body 1 There is a printing roller 4 for printing on the surface of the paper, and the inside of the printing body 1 on the right side of the printing roller 4 is provided with an ultraviolet drying lamp 6 for drying ink marks on the surface of the paper after printing, and the inside of the printing body 1 is There is also a cleaning brush 3 located between the left guide roller group 101 and the printing roller 4, which is used to clean the surface of the paper, and the dust on the surface of the paper is continuously disturbed by the rotation of the roller on the cleaning brush 3. , the printing body 1 is also provided with a dust removal and adsorption assembly 2 for preventing the waste gas generated by printing fr...

Embodiment 2

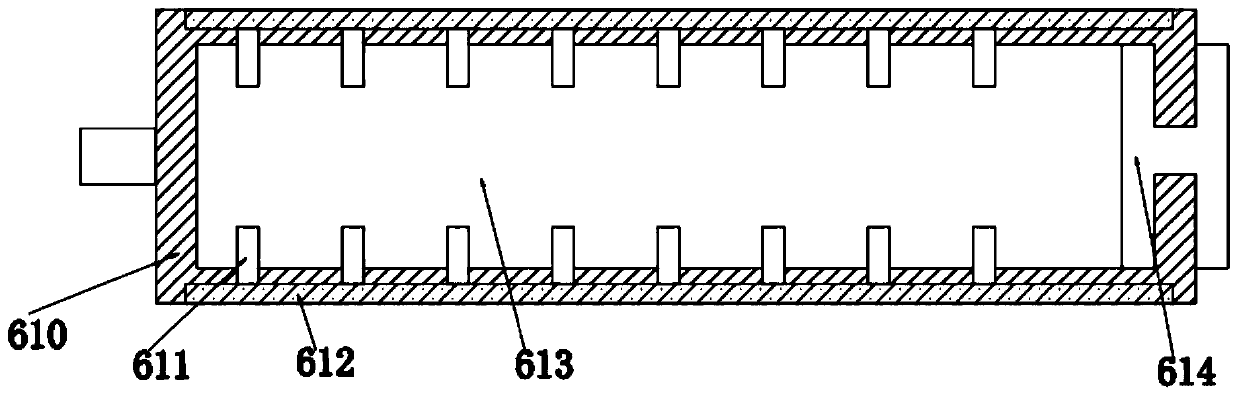

[0039] The difference from Example 1 is: In order to avoid the influence of the temperature rise of the paper on the later coating during printing and drying (higher paper temperature will make the coating layer not easy to shape), the coating calender assembly 8 The inside of the printing body 1 on the left is provided with a set of cooling rollers 61 for cooling the paper. The set of cooling rollers 61 includes a cooling cylinder 610 in contact with the surface of the paper. The inside of the cooling cylinder 610 is provided with a filling layer for absorbing the heat of the paper. 613, the filling layer 613 is preferably water with a larger specific heat capacity. The filling layer 613 is connected to the metal layer 612 wrapped on the outside of the cooling cylinder 610 for direct contact with the paper through several metal heat conducting rods 611. The heat is absorbed and transmitted to the filling layer 613. The end of the cooling cylinder 610 is provided with a semicon...

Embodiment 3

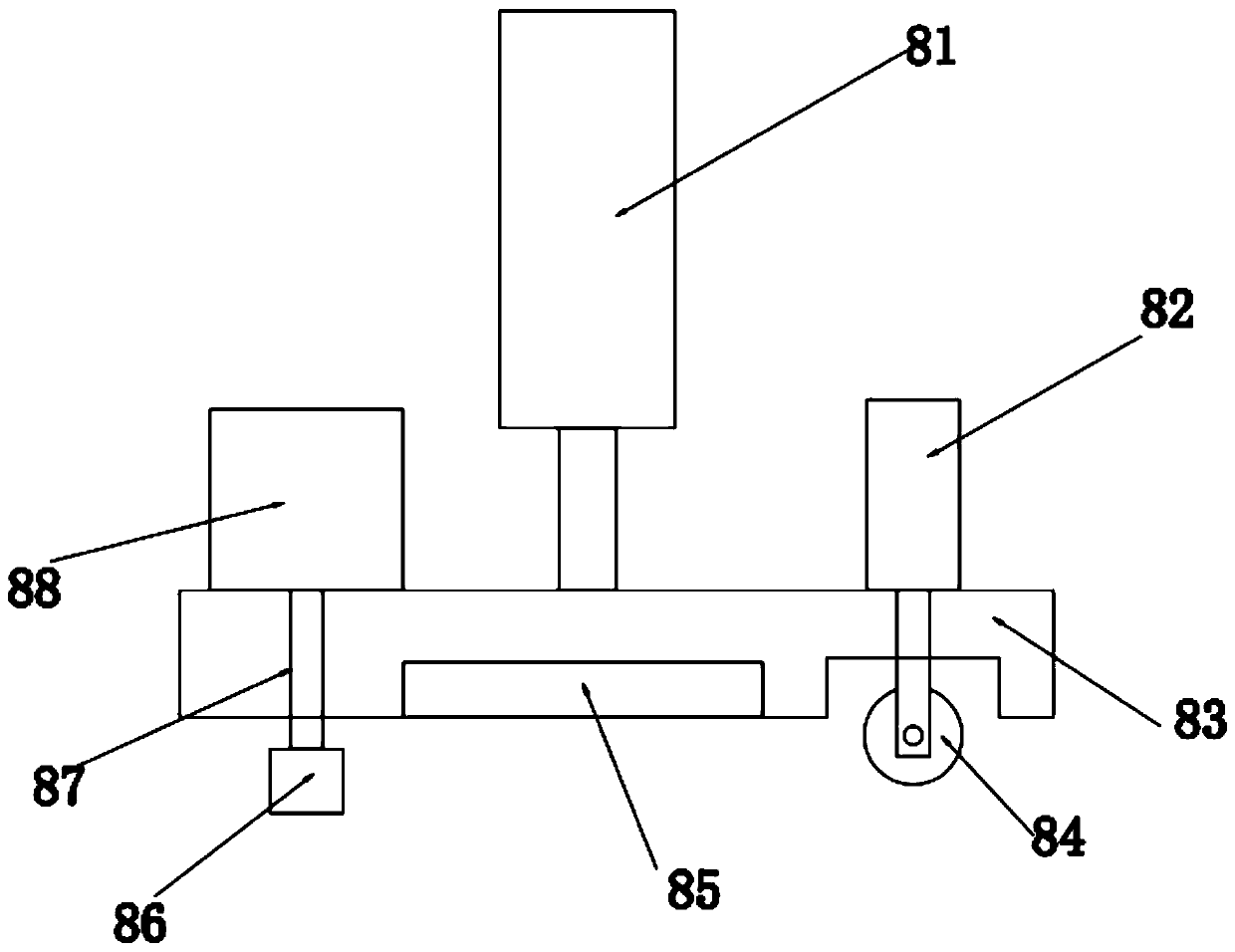

[0041] The difference from Example 1 is that in order to facilitate the control of the printing quality, the inside of the printing body 1 is also provided with a screening assembly for screening printing paper, and the screening assembly includes printing rollers 4 and ultraviolet drying The first camera 5 between the lamps 6 and the second camera 7 arranged on the right side of the coating calender assembly 8 obtain the product quality after printing on the paper through the first camera 5, and obtain the coating quality on the paper through the second camera 7. The quality of the product after the protective layer is convenient for later judgment of the wrong position and helps to determine the maintenance position. The screening assembly also includes a marking assembly 91 arranged at the second camera 7, and the marking assembly 91 includes a telescopic cylinder and a setting The end of the telescopic cylinder is used to stamp the marking head on the surface of the paper. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com