Interlayer film for laminated glass and laminated glass

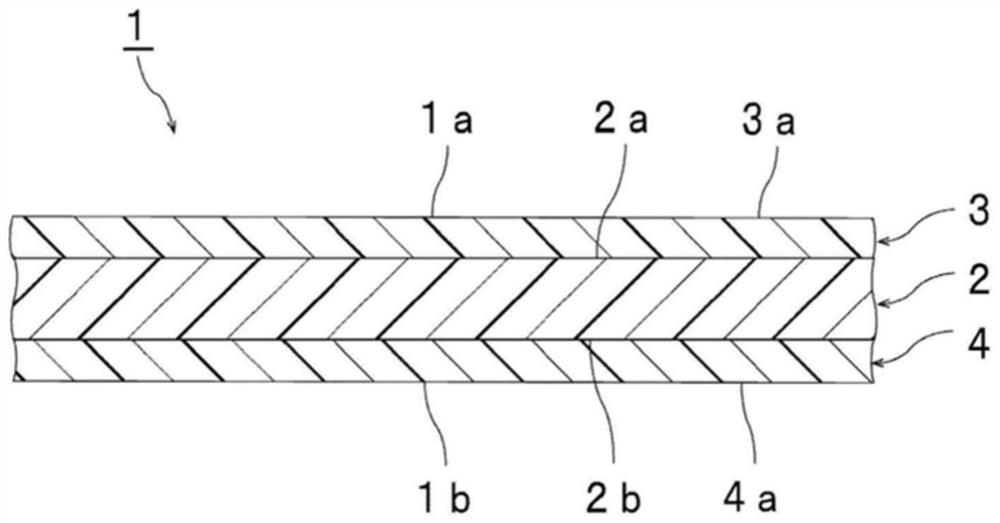

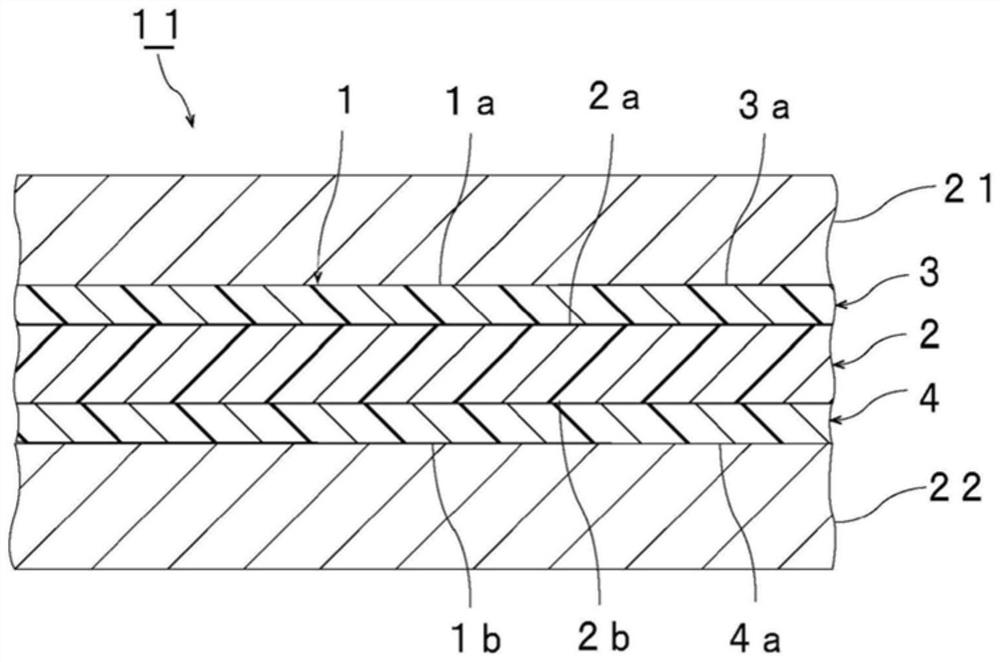

A technology of laminated glass and interlayer, applied in the direction of glass/slag layered products, layered products, synthetic resin layered products, etc., to achieve the effect of preventing voids and suppressing the rise of YI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0181] Preparation of Composition X for Forming the First Layer:

[0182] Polyvinyl acetal resin (polyvinyl butyral (PVB) resin, polyvinyl alcohol (PVA) with an average degree of polymerization of 2300, a hydroxyl content of 23.0 mol%, a degree of acetylation of 12.5 mol%, butyralized 64.5 mol %) 100 parts by weight, 60 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer, TINUVIN 770DF (manufactured by BASF Corporation, N-H (hydrogen atom) type, molecular weight 481) 0.2 parts by weight, 0.2 parts by weight of BHT (2,6-di-tert-butyl-p-cresol, molecular weight 220) and 0.2 parts by weight of Adekastab 3050 (manufactured by ADEKA Corporation, phosphorus-containing antioxidant, molecular weight 503) were mixed to obtain Composition X for forming the first layer was obtained.

[0183] Preparation of composition Y for forming the second and third layers:

[0184] Polyvinyl acetal resin (polyvinyl butyral (PVB) resin, polyvinyl alcohol (PVA) with an av...

Embodiment 2~30 and comparative example 1~5

[0190] As shown in the following Tables 1 to 5, an intermediate film was prepared in the same manner as in Example 1, except that the types and contents of the components contained in the first layer, the second layer, and the third layer were set. and laminated glass.

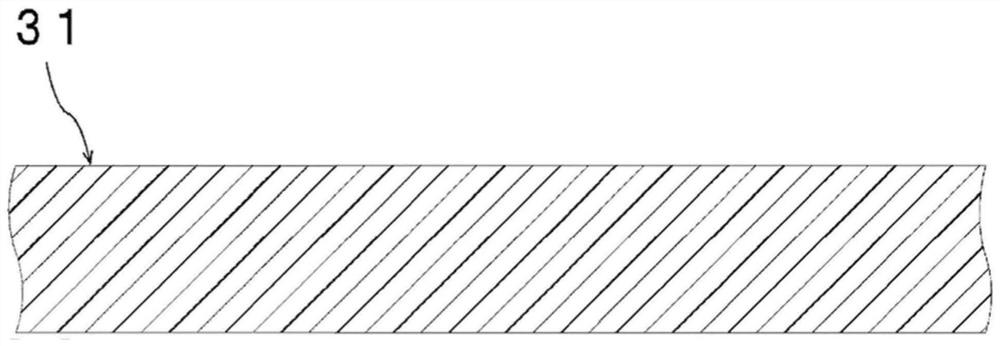

Embodiment 31

[0192] Preparation of Composition X for Forming Intermediate Film (First Layer):

[0193] Polyvinyl acetal resin (polyvinyl butyral (PVB) resin, polyvinyl alcohol (PVA) with an average degree of polymerization of 1700, a hydroxyl content of 30.0 mol%, a degree of acetylation of 1.0 mol%, butyralized 69.0 mol %) 100 parts by weight, 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer, TINUVIN 770DF (manufactured by BASF Corporation, N-H (hydrogen atom) type, molecular weight 481) 0.2 parts by weight, BHT (2,6-di-tert-butyl p-cresol, molecular weight 220) 0.2 parts by weight, Adekastab 3050 (manufactured by ADEKA Corporation, phosphorus-containing antioxidant, molecular weight 503) 0.2 parts by weight and the content Magnesium was mixed in an amount of 60 ppm in the intermediate film to obtain a composition X for forming the intermediate film.

[0194] Preparation of interlayer film:

[0195] The composition for forming an intermediate film was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of acetylation | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com