A shaping and grinding device for die-casting parts

A technology of die-casting parts and liquid storage chambers, which is applied in the field of shaping and grinding devices for die-casting parts. It can solve the problems that the deburring equipment does not have the adjustment function, cannot spray the polishing liquid evenly, and does not have the filtration and recovery of the polishing liquid. Easy to promote and apply, prevent wear and tear, and improve the effect of plastic surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

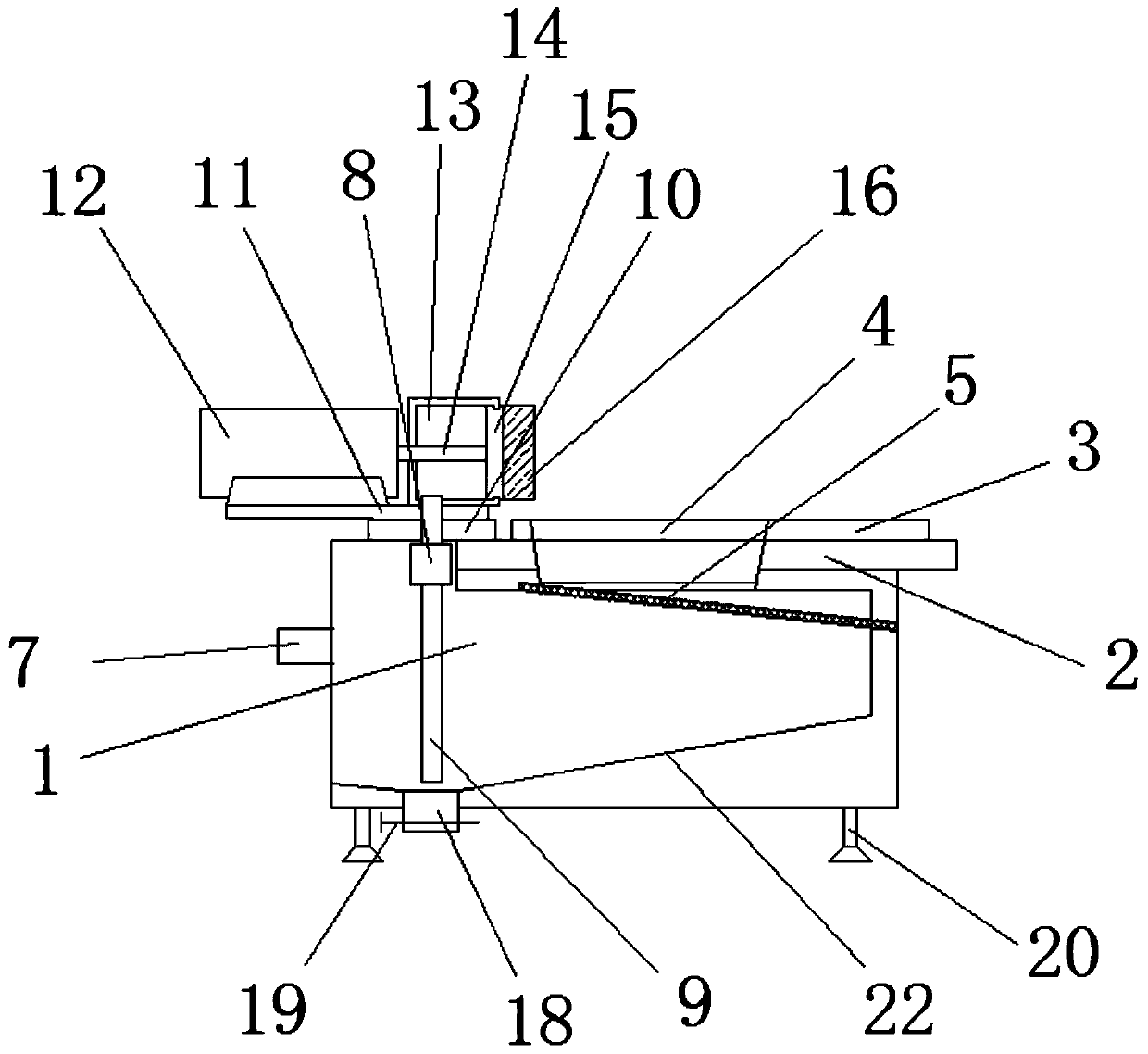

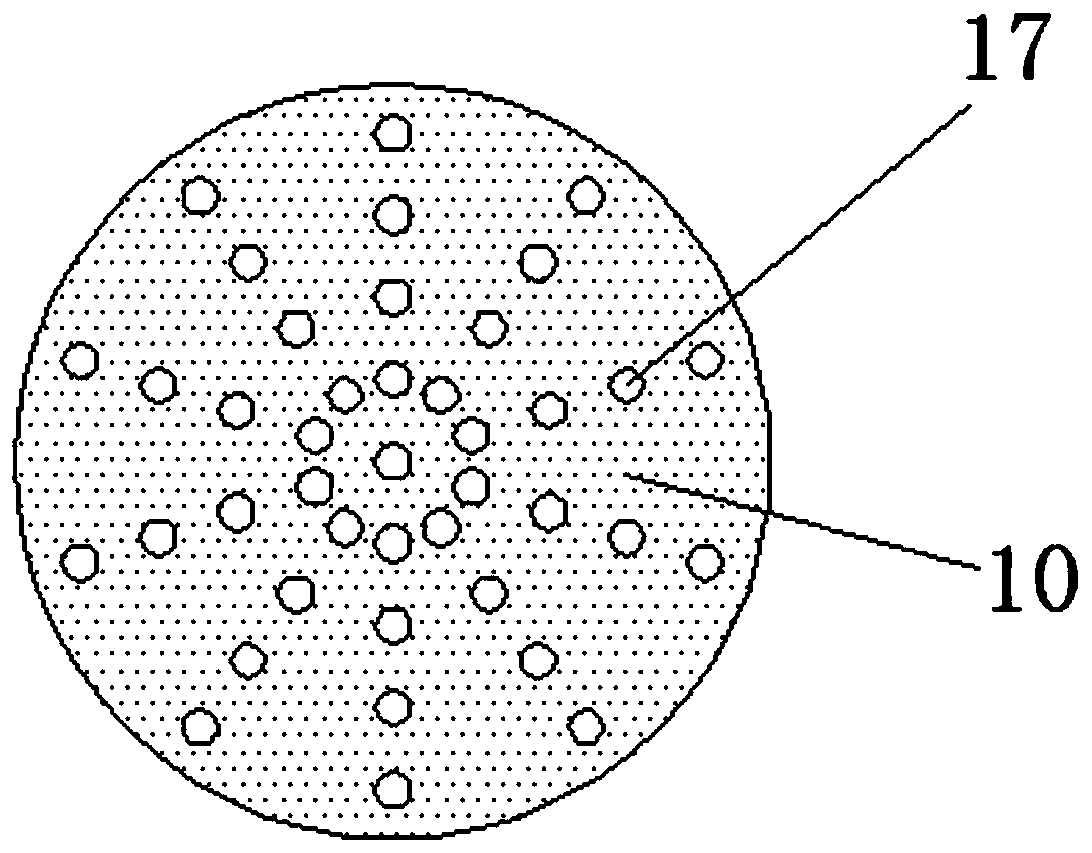

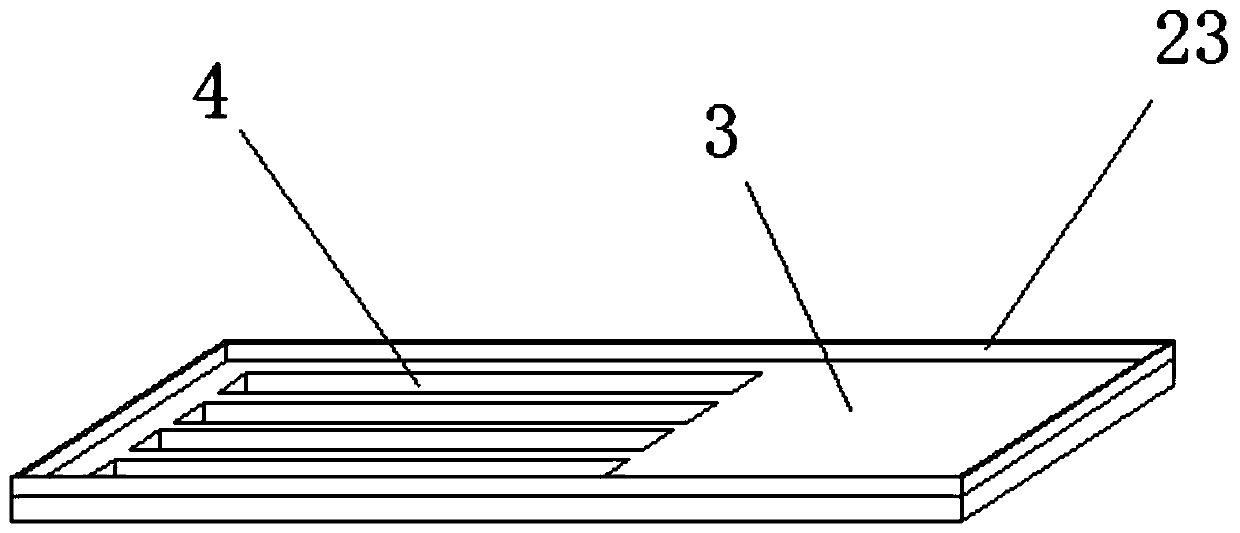

[0022] Embodiment 1: as Figure 1-3 As shown, a shaping and grinding device for die castings includes a liquid storage chamber 1, the bottom of the inner cavity of the liquid storage chamber 1 is obliquely provided with a water guide plate 22, and the bottom of the liquid storage chamber 1 is fixedly installed with four sets of Legs 20, a platform 2 is fixedly installed on the top of the liquid storage chamber 1, a loading platform 3 is fixedly connected to the top of the platform 2, ribs 23 are fixedly connected to the top of the four sides of the loading platform 3, and the storage The top left side of the liquid chamber 1 is fixedly equipped with a turntable 10, the top of the turntable 10 is fixedly connected with a bracket 11, and the bracket 11 is fixedly equipped with a motor 12 and a liquid spray chamber 13, and the right side of the motor 12 Fixedly connected with a rotating shaft 14, the rotating shaft 14 runs through the left side wall of the liquid spray chamber 13...

Embodiment 2

[0023] Embodiment 2: as Figure 1-4 As shown, a shaping and grinding device for die castings includes a liquid storage chamber 1, the bottom of the inner cavity of the liquid storage chamber 1 is obliquely provided with a water guide plate 22, and the bottom of the liquid storage chamber 1 is fixedly installed with four sets of Legs 20, the side wall of the liquid storage chamber 1 is provided with an observation strip 21, the top of the liquid storage chamber 1 is fixedly installed with a platform 2, and the top of the platform 2 is fixedly connected with a loading platform 3, and the loading The top of the four sides of the platform 3 is fixedly connected with ribs 23, the top of the left side of the liquid storage chamber 1 is fixedly installed with a turntable 10, and the top of the turntable 10 is fixedly connected with a bracket 11, and the bracket 11 is fixedly installed with Motor 12 and spray chamber 13, the right side of described motor 12 is fixedly connected with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com