Support catalyst with active metals in atomic-scale dispersion in carrier as well as preparation method and application of catalyst

A supported catalyst and active metal technology, applied in the field of supported catalysts and their preparation, can solve the problems of limiting the application of atomically dispersed supported catalysts, complicated post-processing processes, expensive drugs and raw materials, etc., and achieve high mechanical strength and low cost. , the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

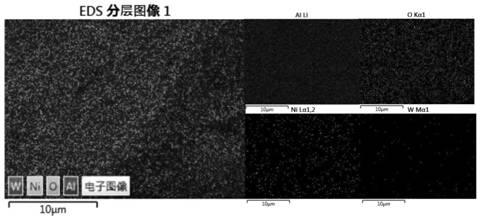

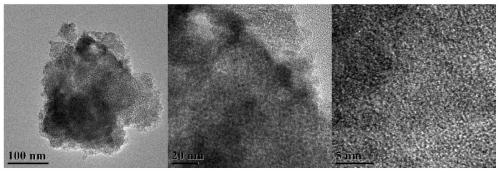

[0061] Dissolve 60.0mL with 0.009mol / L anhydrous NiCl 2 and 0.091mol / L anhydrous AlCl 3 The formamide solution was placed in a polytetrafluoroethylene reactor with a volume of 100.0 mL, and reacted at 180° C. for 12 hours. After the reaction time expires, lower the temperature naturally, take out the solid-liquid mixture, separate the solid and liquid by centrifugation, dry the solid in an oven at 80°C, collect the dry powder, and use a muffle furnace to roast at 450°C for 3 hours to obtain the target product Ni / Al 2 o 3 , the transmission electron microscope photo see figure 1 , the nitrogen adsorption-desorption curve is shown in Figure 14 , XPS Ni2p peak splitting curve see Figure 15 .

Embodiment 2

[0063] In addition to the type B salt anhydrous AlCl 3 Replaced by Ce(NO 3 ) 2 ·6H 2 O, other is the same as embodiment 1, promptly obtains target product Ni / CeO 2 , the transmission electron microscope photo see figure 2 .

Embodiment 3

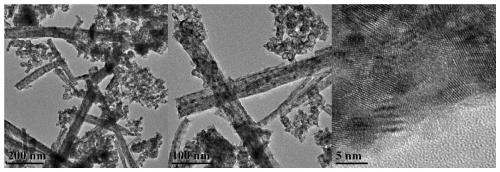

[0065] anhydrous NiCl 2 The concentration is increased to 0.018mol / L, AlCl 3 Concentration is raised to 0.182mol / L, other is the same as embodiment 1, promptly obtains target product Ni / Al 2 o 3 , the transmission electron microscope photo see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com