Negative pressure seed sucking and mechanical seed cleaning type precise seed-metering device and seed-metering method thereof

A seed cleaning and metering device technology, applied to the parts of the planter, etc., can solve the problems of the wear of the seeding device, the coordination of the seeding speed and seeding quality, and the influence of the overall work of the air chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

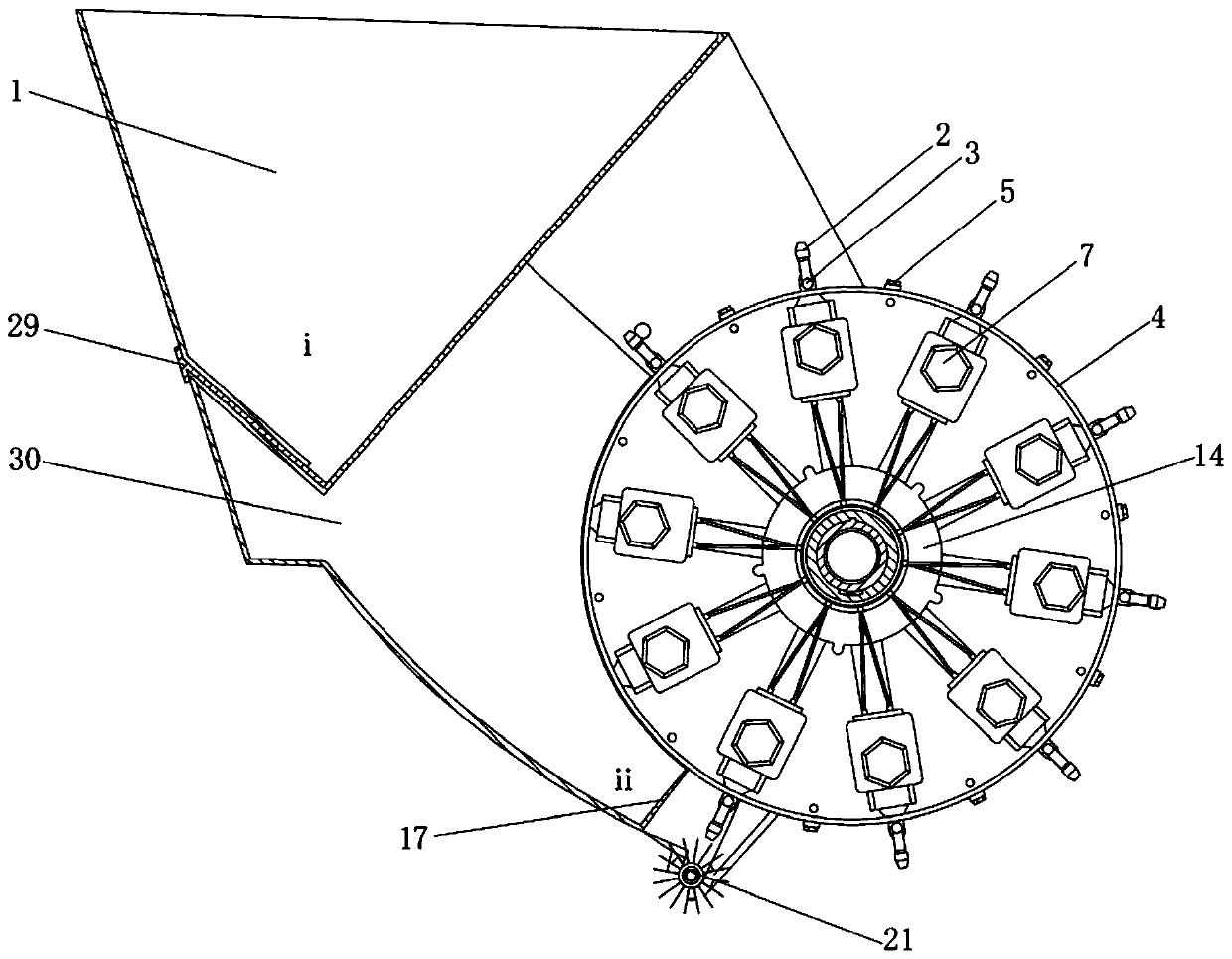

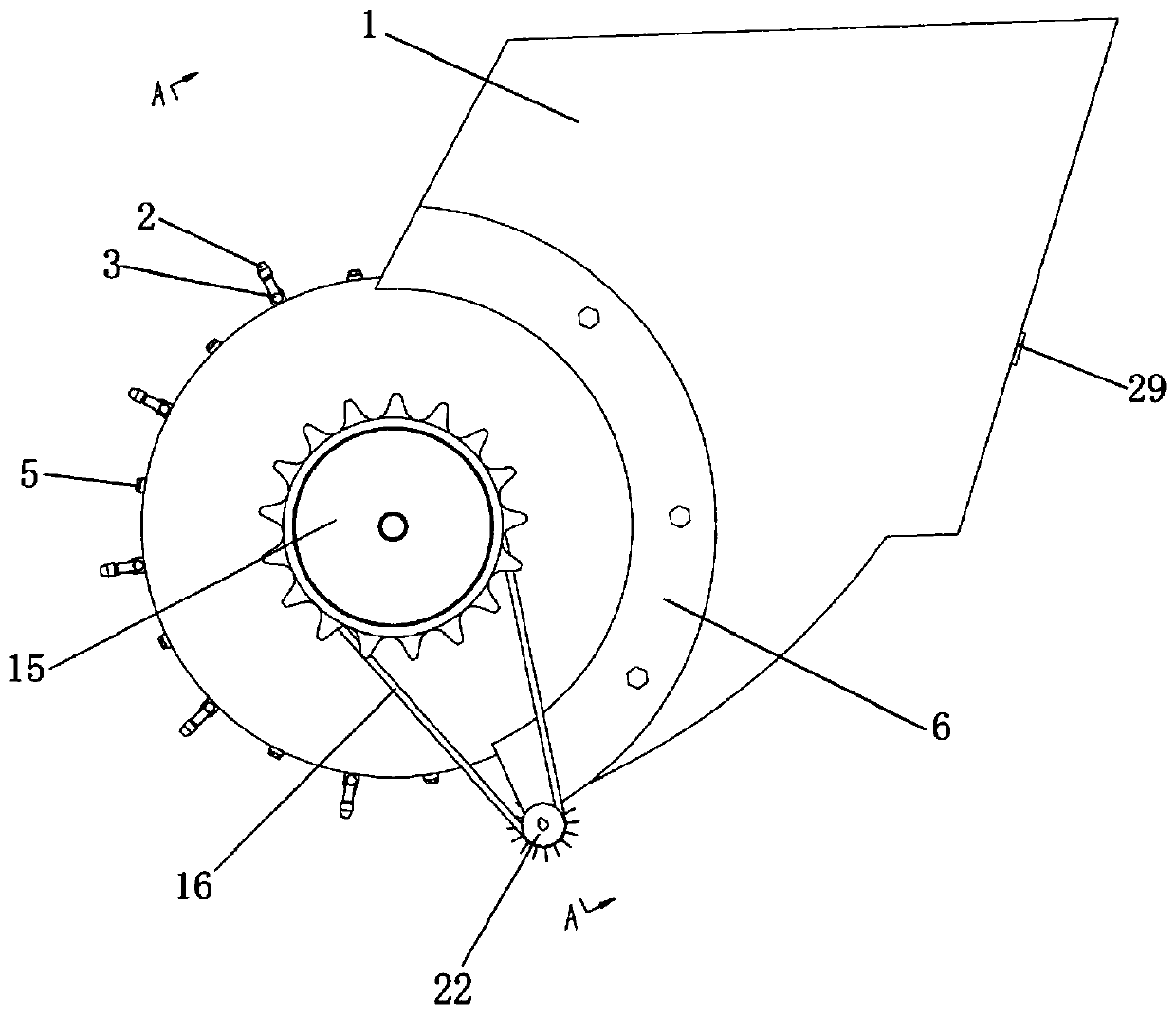

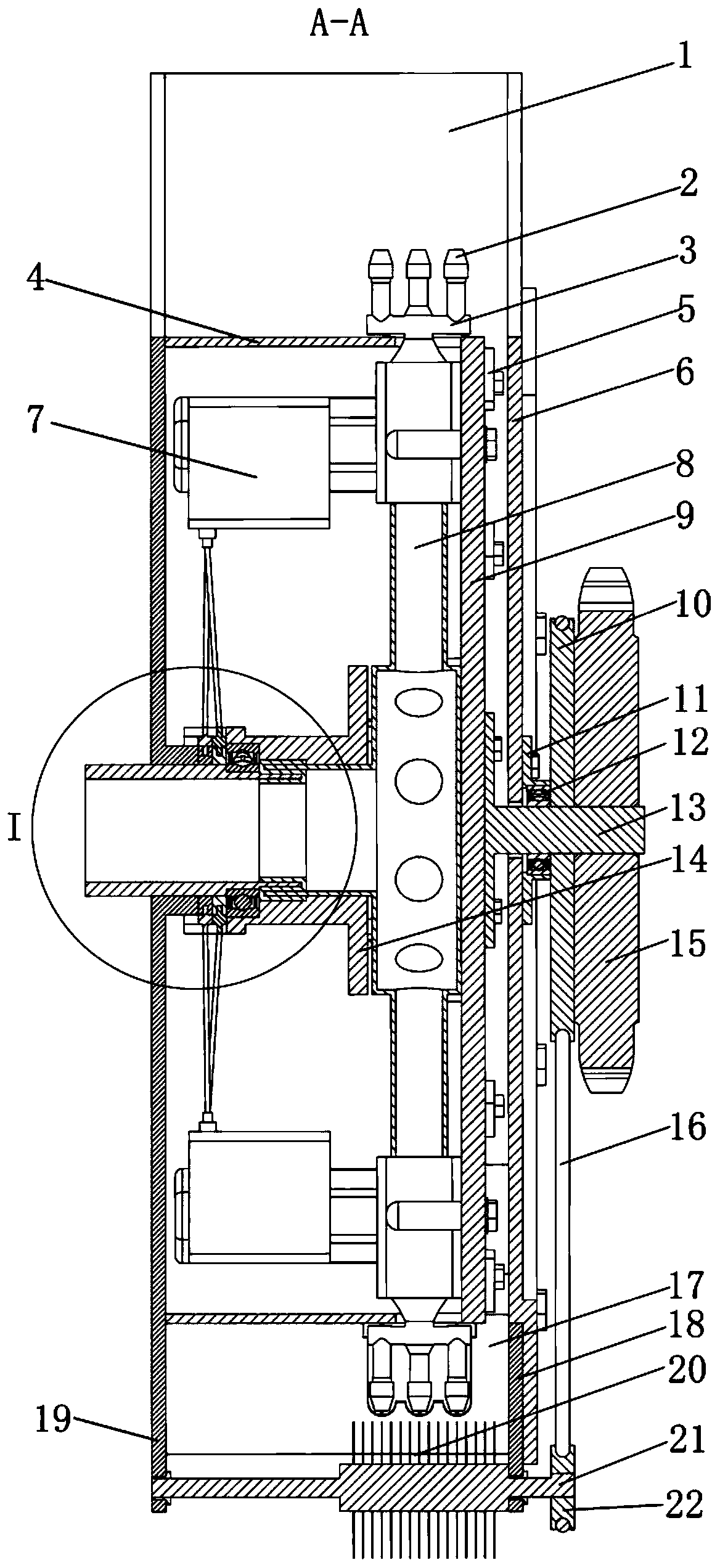

[0036] Such as Figure 1~5 As shown, a negative pressure seed suction mechanical seed cleaning type precision seed metering device includes a seed chamber 1, a seed suction nozzle 2, a seed suction branch pipe 3, a side panel 4, a side panel fixing piece 5, a right cover plate 6, two Position three-way solenoid valve 7, intermediate pipe 8, support disc 9, sowing sprocket 10, bearing seat 11, bearing 12, main shaft 13, support frame 14, power wheel 15, transmission chain 16, flexible seed retaining plate 17, right side Plate 18, left side plate 19, brush 20, brush shaft 21, brush sprocket 22, combined brush ring 23, main control slip ring guide rail 24, negative pressure chamber 25, support frame bearing 26, sealing ring 27 , Negative electrode slip ring guide rail 28, current limiting plate 29, intermediate partition 30, lead 31, non-conductive track 32, conductive trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com