Correction Method of Ultrasonic Flowmeter with Frequency Drift Correction Function

A frequency drift, ultrasonic technology, used in the measurement of flow/mass flow, liquid/fluid solid measurement, measurement devices, etc., can solve the problem of different degrees of resonance drift, affecting the measurement accuracy and stability of ultrasonic flowmeters, and the frequency of the driving signal. Unable to maintain consistency and other problems, to achieve the effect of ensuring echo quality, realizing automatic gain control, and improving accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

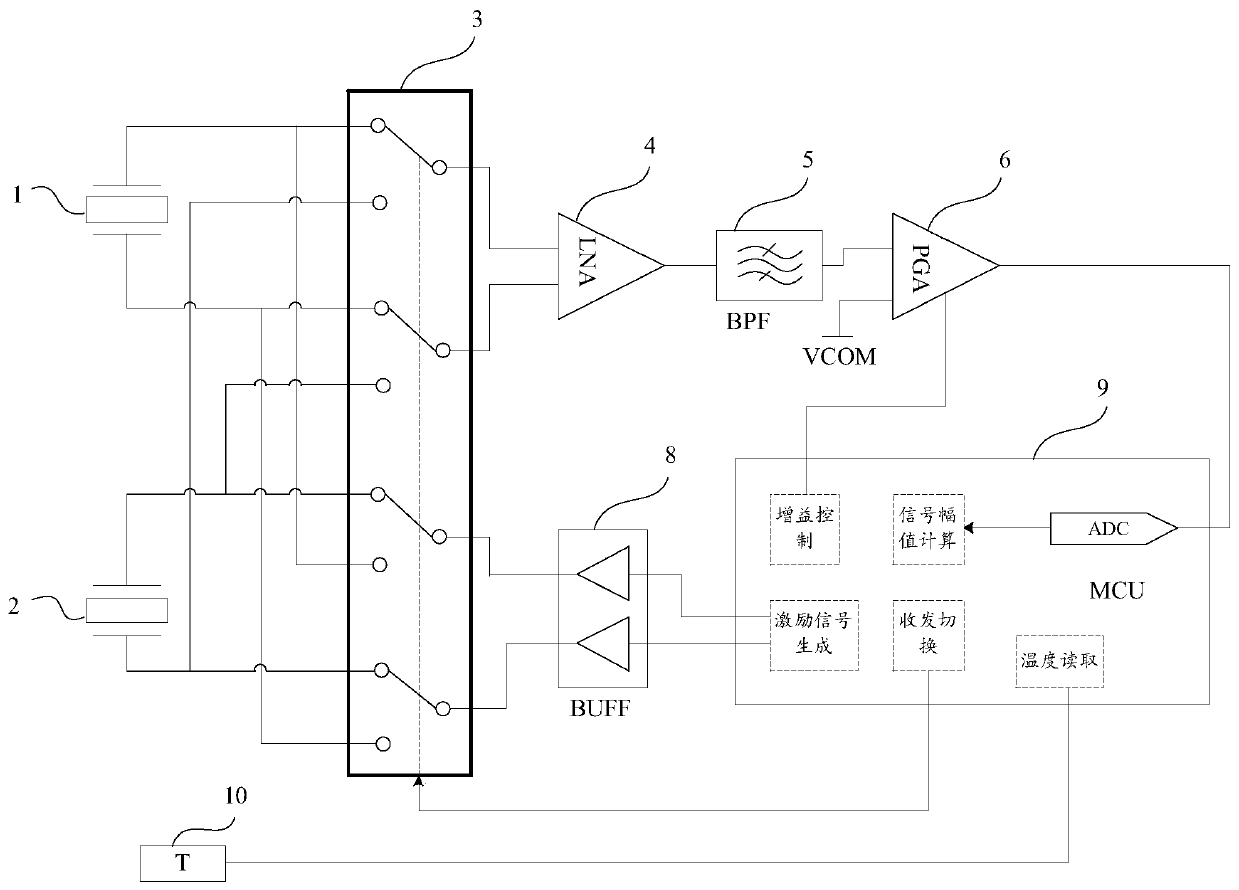

[0033] Such as figure 1 As shown, the embodiment of the present application provides a structural block diagram of an ultrasonic flowmeter with a frequency drift correction function, including an upstream transducer 1, a downstream transducer 2, a signal switching switch 3, a low noise amplifier 4, and a bandpass filter Device 5, variable gain amplifier 6, microcontroller 9, temperature sensor 10, excitation signal buffer 8, analog-to-digital converter ADC.

[0034] The upstream transducer 1 and the downstream transducer 2 are respectively connected to the signal switching switch 3; through the signal switching switch, the upstream transducer 1 and the downstream transducer 2 are alternately used as the transmitting transducer and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com