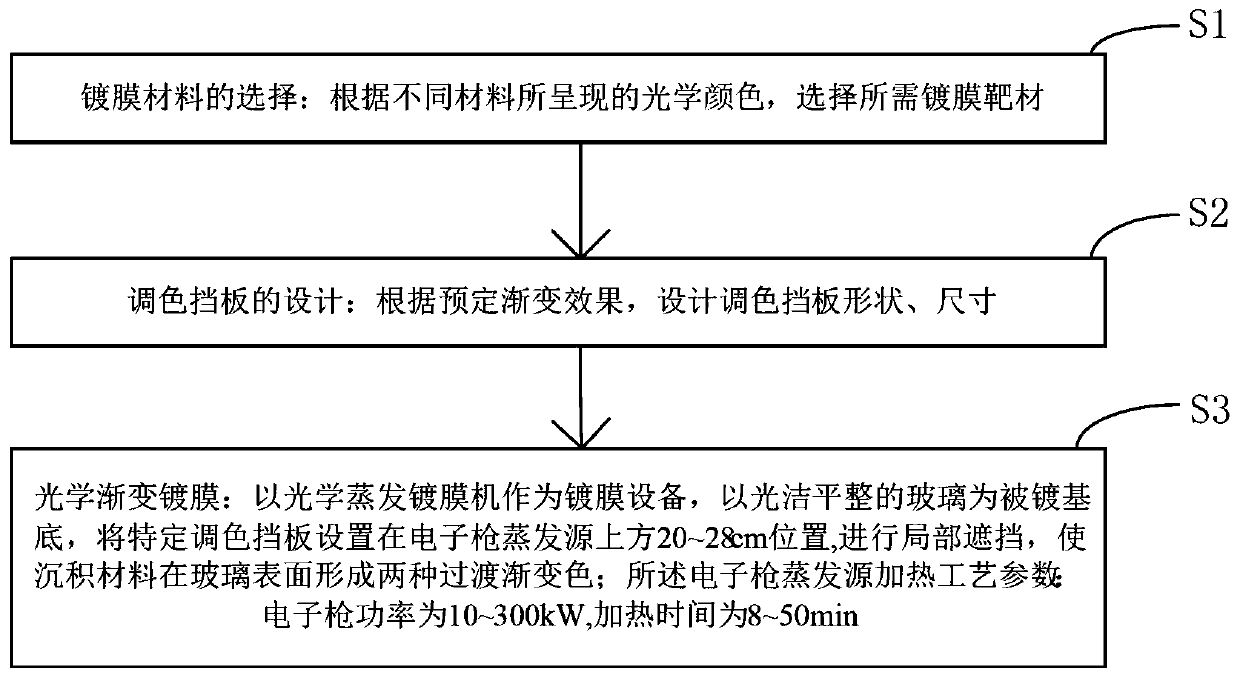

Film-coating method for forming gradient colors on glass surface

A glass surface, gradient color technology, applied in coatings and other directions, can solve problems such as violations and immature borderless designs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

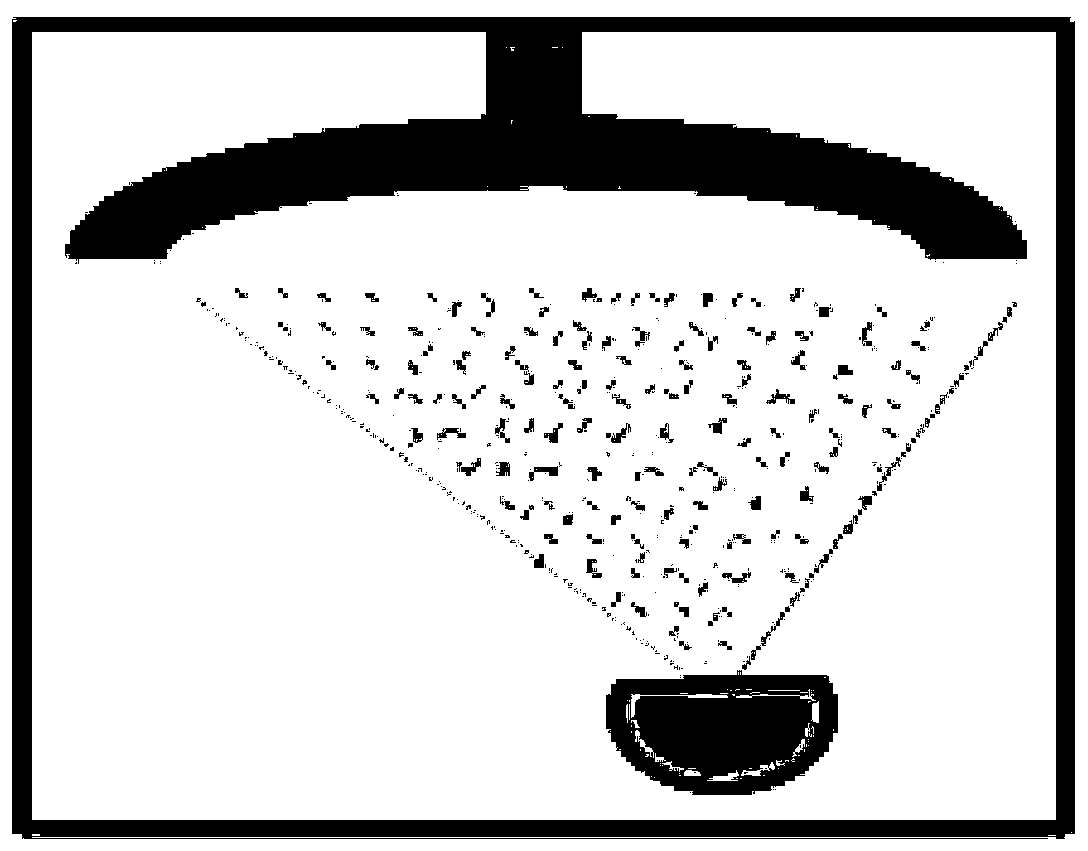

[0028] The present invention provides a specific embodiment of a coating method for forming gradient colors on the surface of glass. The coating equipment used in the method is an optical evaporation coating machine. The high-voltage electric field between the anodes is accelerated and focused, deflected by the magnetic field to reach the surface of the crucible evaporation material, the evaporation material is heated, the molecules of the evaporation material overflow, gasify and evenly deposit and adhere to the surface of the substrate to form a coating (the film coated in this state Uniform layer distribution is a conventional coating process), and the schematic diagram of the above working principle is shown in figure 1 ;

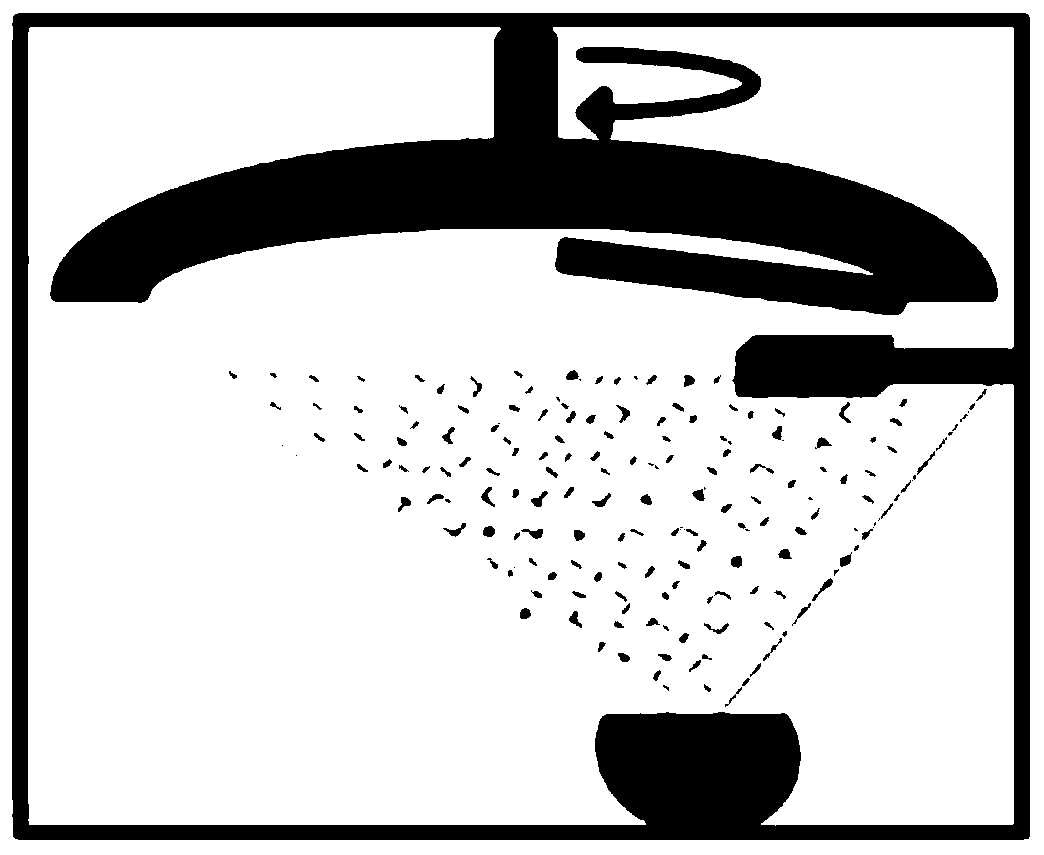

[0029] The coating method for forming gradient colors on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com