Nanoparticle liquid with oxidase activity and preparation method

A platinum nanoparticle, oxidase activity technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., to achieve the effect of simple method, high catalytic activity and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a platinum nanoparticle liquid with oxidase activity, comprising the steps of:

[0027] (1) Add 50 μL of 50 mM cytidine-5'-monophosphate disodium salt ethylene glycol solution into a 1.5 mL centrifuge tube;

[0028] (2) Add 50 μL of 50 mM potassium tetrachloroplatinate aqueous solution to the solution obtained in step (1), add ethylene glycol to make the total volume 500 μL, shake and mix, and stand at 60°C for 24 hours to obtain a solution with oxidase activity platinum nanoparticles liquid. Liquid (being called as CMP-Pt1.0 liquid), obtains its average particle diameter by transmission electron microscope scanning and is 3.3nm (see figure 1 ).

[0029] Determination of Oxidase Activity in Platinum Nanoparticle Liquid:

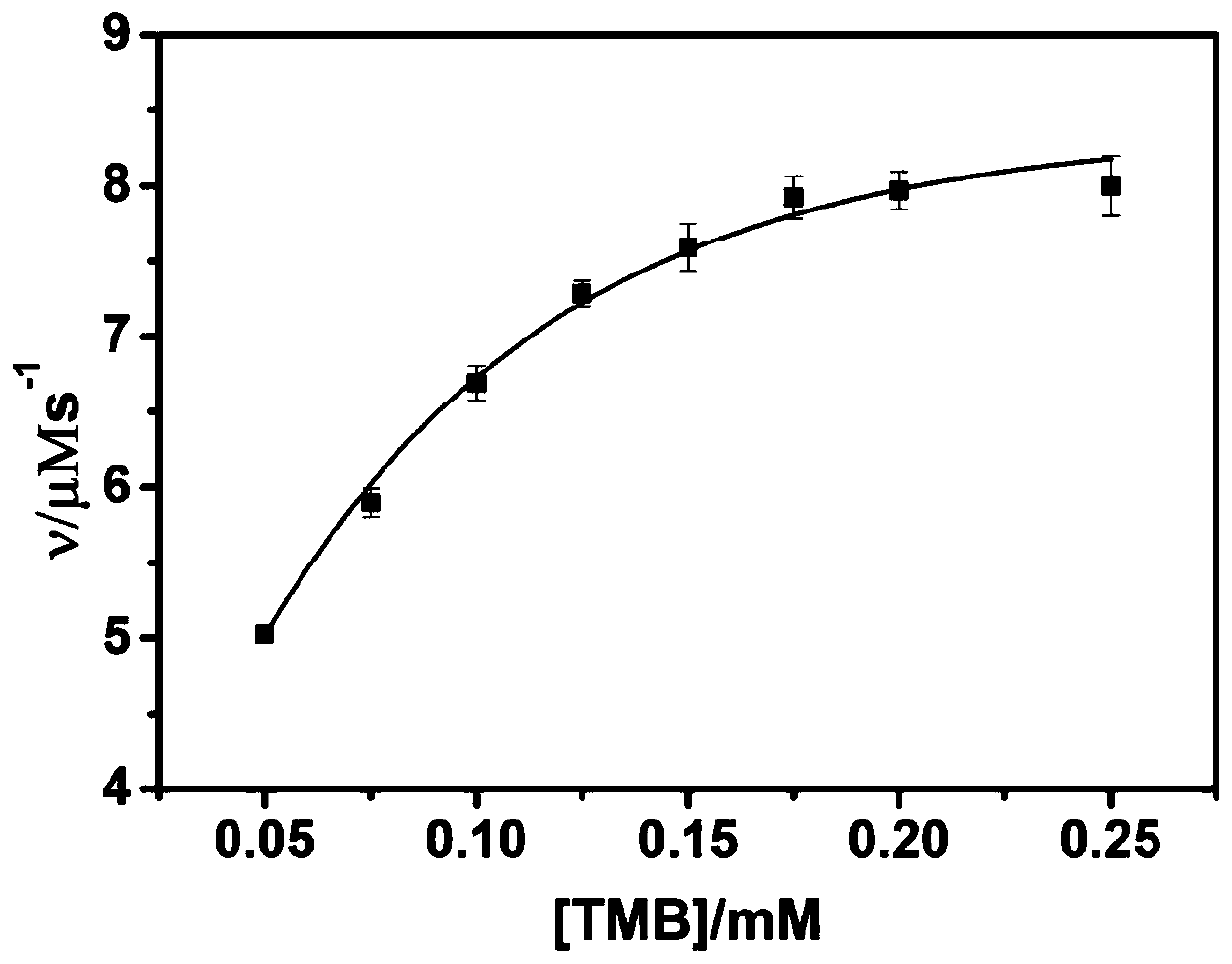

[0030] Take 20 μL of the platinum nanoparticle liquid with oxidase activity obtained in Example 1 in a 1.5mL centrifuge tube and add 980 μL of distilled water to dilute and mix evenly. In eight 4mL cuvettes, add 20 μL of the a...

Embodiment 2

[0033] A method for preparing a platinum nanoparticle liquid with oxidase activity, comprising the steps of:

[0034] (1) Add 100 μL of 5mM cytidine-5'-monophosphate disodium salt ethylene glycol solution into a 1.5mL centrifuge tube;

[0035] (2) Add 25 μL of 100 mM potassium tetrachloroplatinate aqueous solution to the solution obtained in step (1), add ethylene glycol to make the total volume 500 μL, shake and mix, and let stand at 20°C for 72 hours to obtain platinum nanoparticles liquid. The liquid (named as CMP-Pt0.2 liquid) has an average particle size of 3.1 nm obtained by scanning with a transmission electron microscope.

[0036] Determination method is the same as embodiment 1, to the K of 3,3',5,5'-tetramethylbenzidine m The value is 0.064mM.

Embodiment 3

[0038] A method for preparing a platinum nanoparticle liquid with oxidase activity, comprising the steps of:

[0039] (1) Add 50 μL of 250 mM cytidine-5'-monophosphate disodium salt ethylene glycol solution into a 1.5 mL centrifuge tube;

[0040] (2) Add 100 μL of 25 mM potassium tetrachloroplatinate aqueous solution to the solution obtained in step (1), add ethylene glycol to make the total volume 500 μL, shake and mix well, and let stand at 80°C for 12 hours to obtain a solution with oxidase activity platinum nanoparticles liquid. The liquid (named as CMP-Pt5.0 liquid) has an average particle size of 3.7 nm obtained by scanning with a transmission electron microscope.

[0041] Determination method is the same as embodiment 1, to the K of 3,3',5,5'-tetramethylbenzidine m The value is 0.048mM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Km value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com