Organic amine modified graphene oxide/polymer composite film and its preparation and application

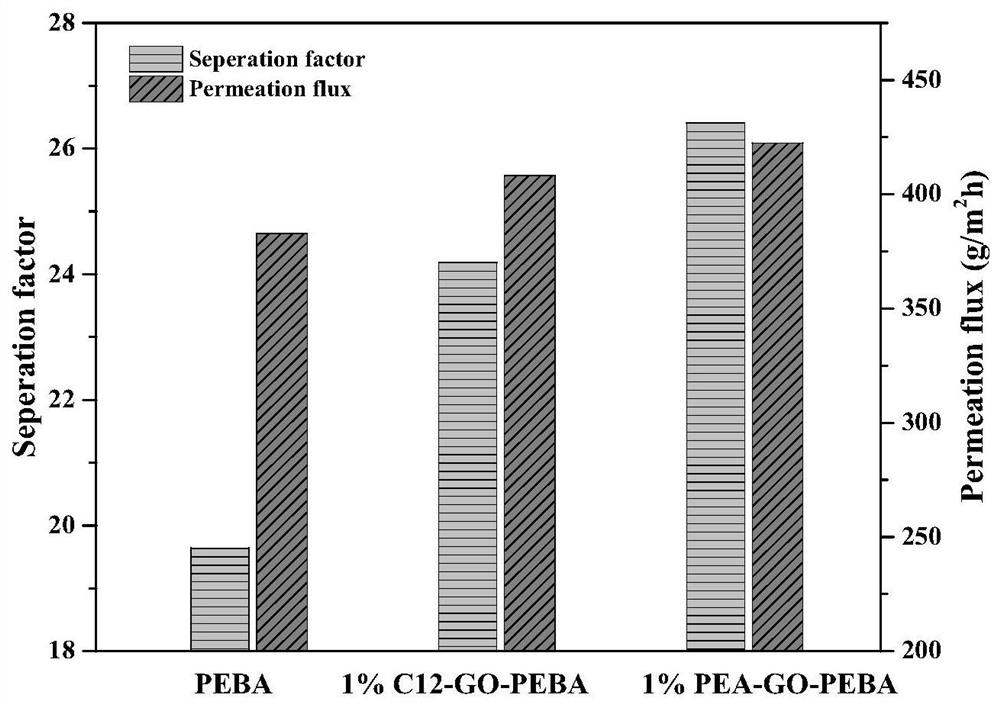

A technology of polymer membrane and organic amine, which is applied in the field of organic amine modified graphene oxide/polymer composite membrane, can solve the problems of poor stability of GO layer, complicated membrane making method, and large dosage, so as to improve the separation factor and permeation flux, membrane structure optimization, and enhanced hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

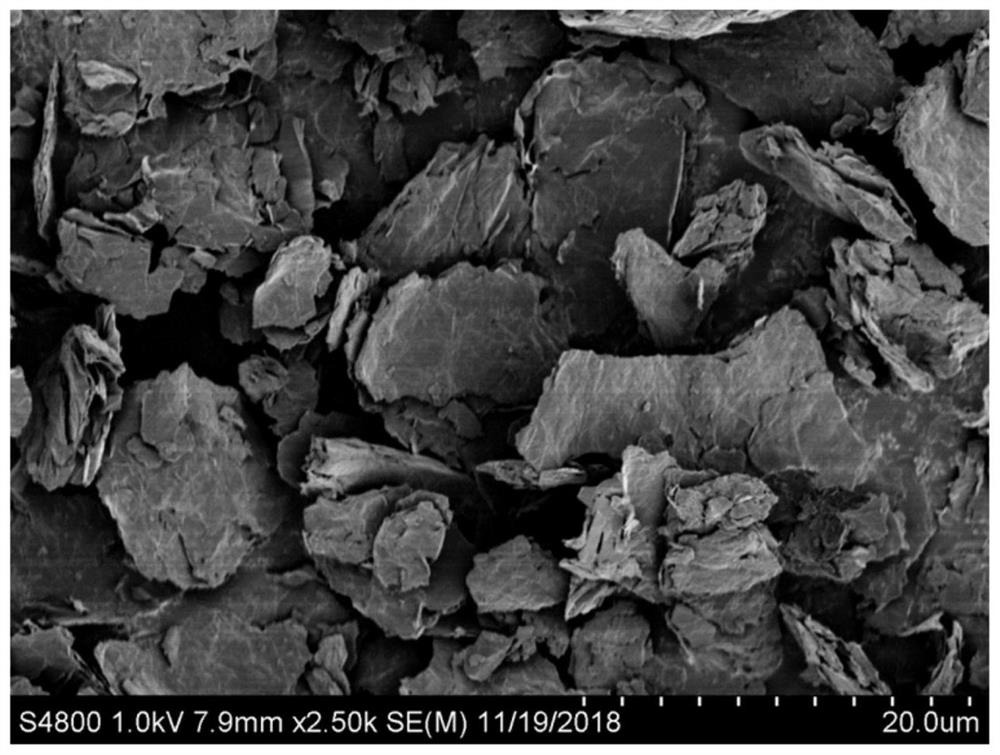

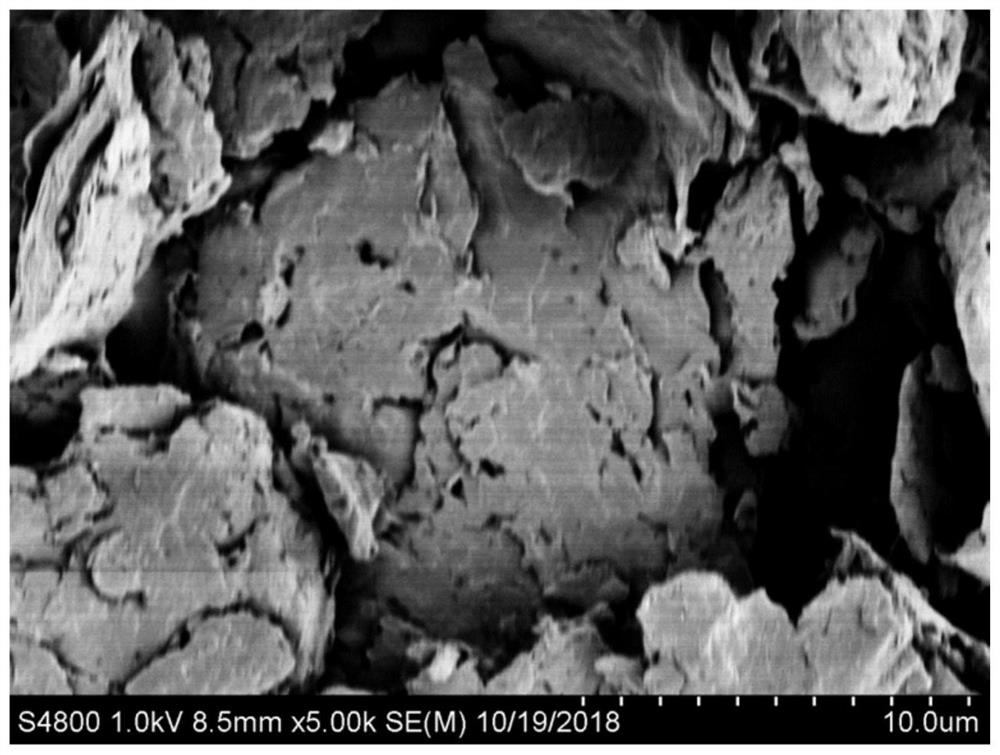

[0040] An organic amine modified graphene oxide / polymer composite membrane, the composite membrane includes a pervaporation membrane and an organic amine modified graphene oxide powder dispersed therein, the organic amine modified graphene oxide powder is formed by organic amine and oxidation Oxygen-containing functional groups on the surface of graphene were formed by reaction, wherein the graphene oxide powder was commercially available graphene oxide (GO, with a sheet diameter of 0.5-5 μm), the organic amine was polyetheramine D-230, and the pervaporation membrane material was poly Ether block copolyamide (PEBA), the mass ratio of organic amine modified graphene oxide powder (PEA-GO) to PEBA is about 1:100, this composite membrane can be applied in butanol / water system pervaporation separation of butanol , the specific preparation steps of the composite membrane are as follows:

[0041] Weigh a certain mass of graphene oxide powder and add an appropriate amount of N,N-dimet...

Embodiment 2

[0043]An organic amine modified graphene oxide / polymer composite membrane, the composite membrane includes a pervaporation membrane and an organic amine modified graphene oxide powder dispersed therein, the organic amine modified graphene oxide powder is formed by organic amine and oxidation Oxygen-containing functional groups on the surface of graphene are formed by reaction. Among them, the graphene oxide powder is commercially available graphene oxide (GO, with a sheet diameter of 0.5-5 μm), the organic amine is dodecylamine, and the pervaporation membrane material is polyether Block copolyamide (PEBA), the mass ratio of organic amine-modified graphene oxide powder (C12-GO) to PEBA is about 1:100, this composite membrane can be applied in butanol / water system pervaporation separation of butanol, The concrete preparation steps of this composite film are as follows:

[0044] Weigh a certain mass of graphene oxide powder and add an appropriate amount of n-hexane to stir proper...

Embodiment 3

[0049] This embodiment is basically the same as Embodiment 1, except that, in this embodiment, D400 polyetheramine is selected as the organic amine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com