Fireproof door

A technology of fire doors and fire bars, which is applied in the field of fire doors, can solve problems such as dense smoke, large safety hazards, and unfavorable escape, and achieve the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

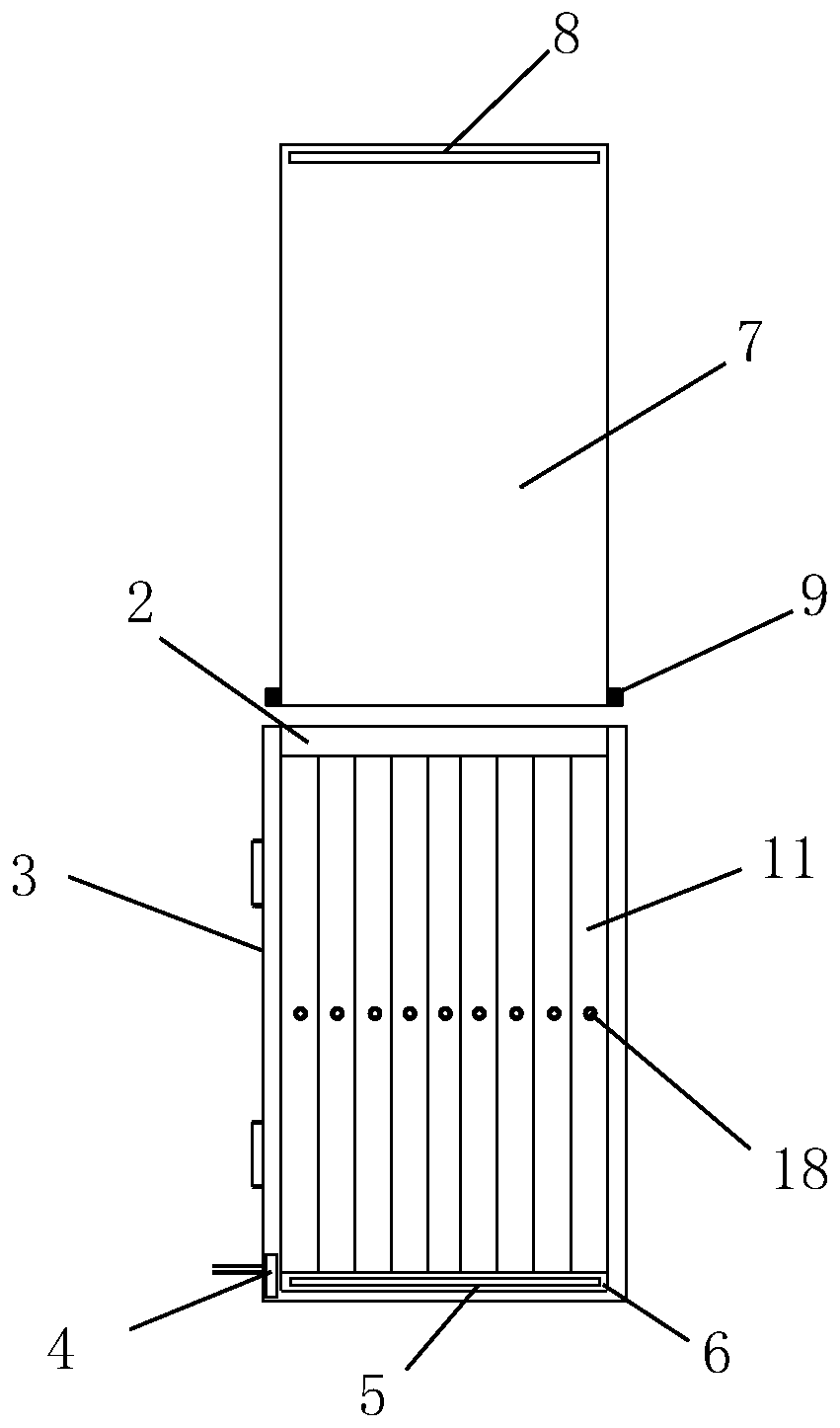

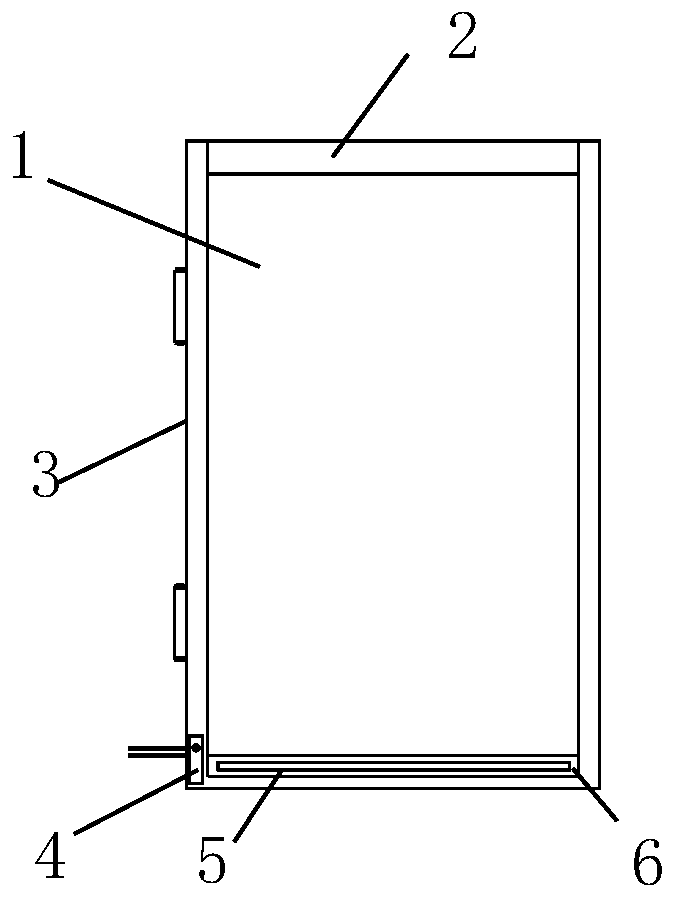

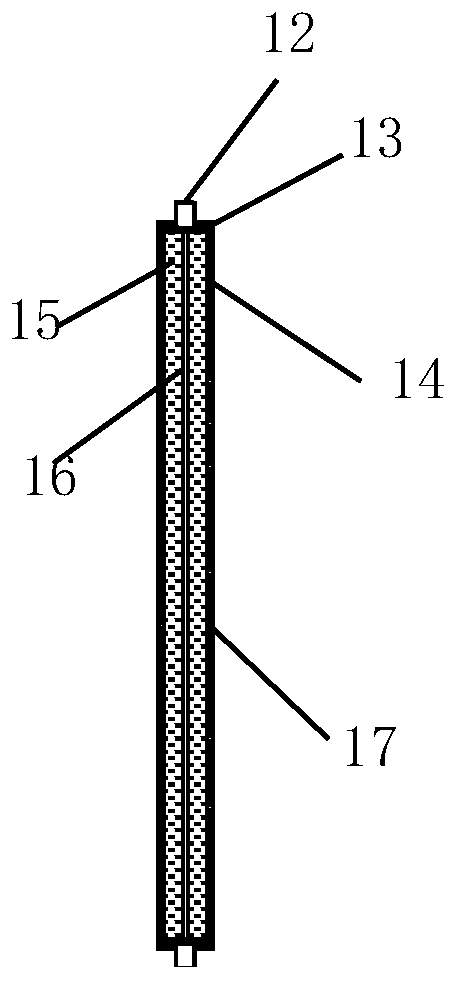

[0022] Such as figure 1 with figure 2 As shown, a fire door includes a door frame 3, a hollow cavity 1 through which the door frame 3 has a middle, and the upper and lower sides of the hollow cavity 1 are respectively provided with more than one group of symmetrical first shaft holes (not shown), the hollow There are more than one flexible fireproof rods 11 arranged side by side in the cavity 1. The fireproof rods 11 and the fireproof rods 11 are in sealing contact with each other and the entire hollow cavity 1 is sealed by more than one fireproof rods 11. The upper and lower sides of the fireproof rods 11 are respectively vertical. A first rotating shaft 12 is provided, and the first rotating shafts 12 are respectively rotated and installed in the first rotating shaft holes (not shown) above and below the hollow cavity, and an escape gap cavity is formed between two adjacent fireproof rods 11;

[0023] The front and back of the door frame 3 are respectively provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com